MXene/Ni3S2 electrode and preparation method and application in electro-catalysis hydrogen preparation thereof

An electrocatalysis and electrode technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., to achieve the effect of great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

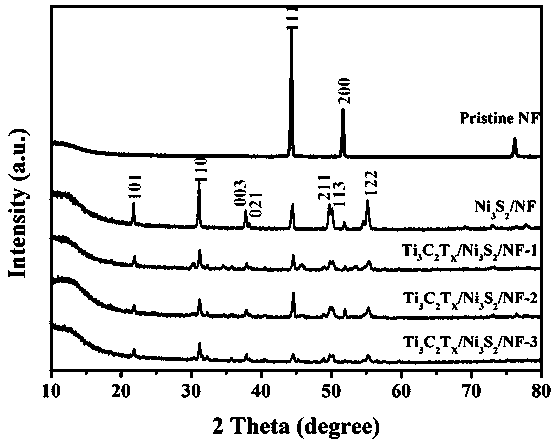

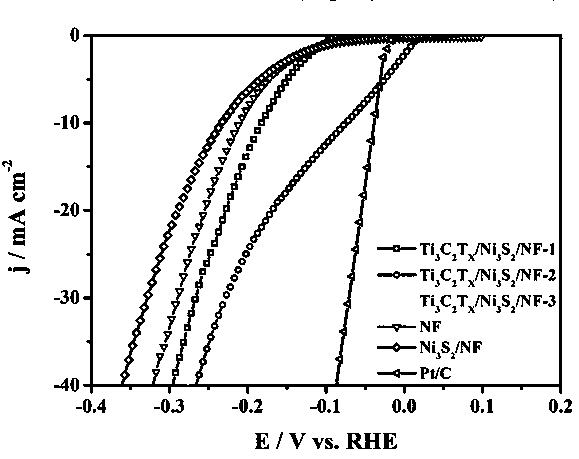

Embodiment 1

[0012] First, 1 cm × 1 cm × 1 mm nickel foam was ultrasonicated in 6 M hydrochloric acid, acetone and deionized water for 15 min each, and then vacuum-dried at 60 °C for future use. At room temperature, 2g Ti 3 AlC 2 Slowly added to 40 ml HF solution (40wt%), magnetically stirred at 200 r / min for 24 h. Afterwards, centrifuge at 3500 r / min for 2 min, pour off the supernatant, add water and centrifuge again, and repeat this many times until the pH is about neutral. The lower precipitate was collected and dried under vacuum at 60°C. Take 0.5 g of dried precipitate and 0.25 g of CTAB in 15 mL of deoxygenated water and stir for 3 h, then add a piece of dried nickel foam to the above solution and continue stirring for 3 h. Finally, the mixed solution was transferred to a high-temperature and high-pressure reactor and reacted at 160 °C for 4 h. After natural cooling, the nickel foam was washed with deionized water and absolute ethanol and dried at 60°C to obtain the obtained sam...

Embodiment 2

[0014] First, 1 cm × 1 cm × 1 mm nickel foam was ultrasonicated in 6 M hydrochloric acid, acetone and deionized water for 15 min each, and then vacuum-dried at 60 °C for future use. At room temperature, 2g Ti 3 AlC 2 Slowly added to 40 ml HF solution (40wt%), magnetically stirred at 200 r / min for 24 h. Afterwards, centrifuge at 3500 r / min for 2 min, pour off the supernatant, add water and centrifuge again, and repeat this many times until the pH is about neutral. The lower precipitate was collected and dried under vacuum at 60°C. Take 0.5 g of dried precipitate and 0.25 g of CTAB in 15 mL of deoxygenated water and stir for 3 h, then add 6 mmol of thioacetamide and a piece of dried nickel foam to the above solution and continue to stir for 3 h. Finally, the mixed solution was transferred to a high temperature and high pressure reactor and reacted at 160° C. for 4 h. After natural cooling, the nickel foam was washed with deionized water and absolute ethanol and dried at 60 ...

Embodiment 3

[0016] First, 1 cm × 1 cm × 1 mm nickel foam was ultrasonicated in 6 M hydrochloric acid, acetone and deionized water for 15 min each, and then vacuum-dried at 60 °C for future use. At room temperature, 2g Ti 3 AlC 2 Slowly added to 40 ml HF solution (40wt%), magnetically stirred at 200 r / min for 24 h. Afterwards, centrifuge at 3500 r / min for 2 min, pour off the supernatant, add water and centrifuge again, and repeat this many times until the pH is about neutral. The lower precipitate was collected and dried under vacuum at 60°C. Take 0.5 g of dried precipitate and 0.25 g of CTAB in 15 mL of deoxygenated water and stir for 3 h, then add 9 mmol of thioacetamide and a piece of dried nickel foam to the above solution and continue to stir for 3 h. Finally, the mixed solution was transferred to a high temperature and high pressure reactor and reacted at 160° C. for 4 h. After natural cooling, the nickel foam was washed with deionized water and absolute ethanol and dried at 60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com