Negative bending moment steel bundle tensioning connector and bridge construction for simply supported continuous bridge

A simply supported variable continuous, negative bending moment technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of bridge quality, unreasonable structural form, etc., to shorten the age difference, improve the connection reliability, The effect of reducing the shrinkage of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

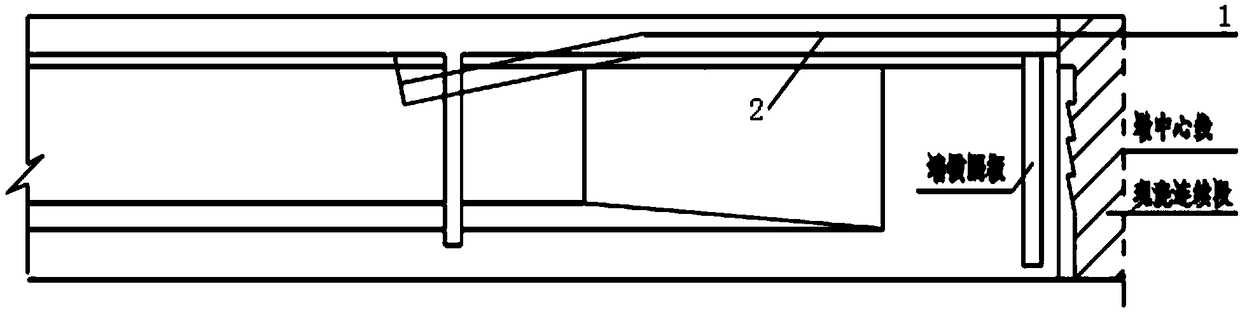

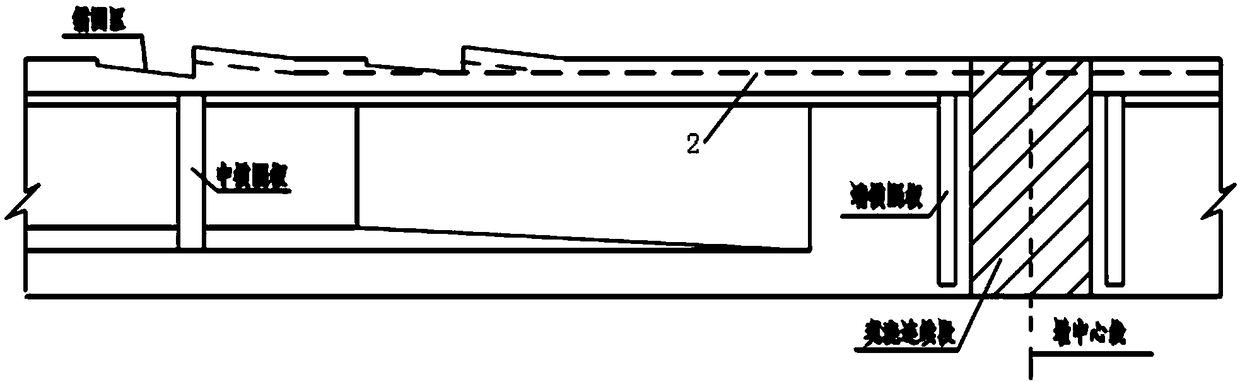

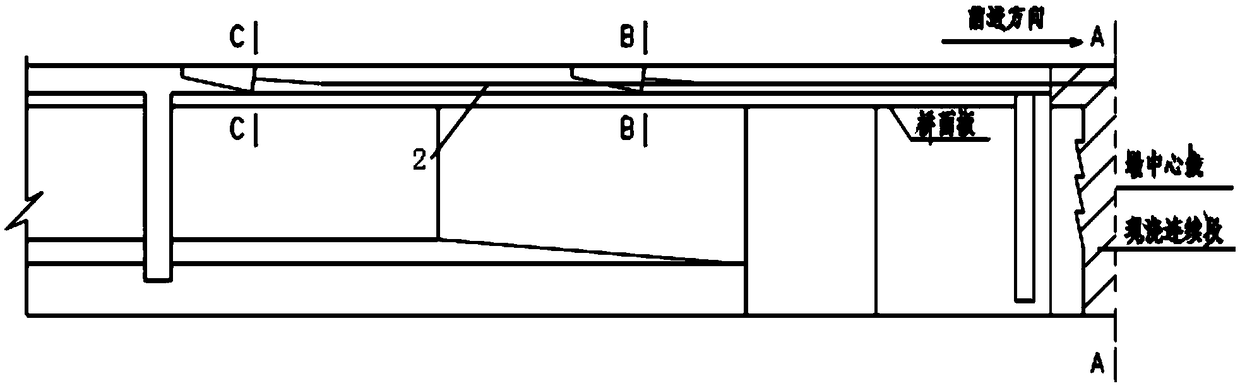

[0041] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0042]A simply supported variable continuous bridge negative moment steel beam tension connector, including a bellows 1 and a steel beam 2 inserted in the bellows 1, one end of the steel beam 2 is provided with an anchoring device 3, and also includes a steel beam 2 The other end matches the connecting screwing mechanism 4; the connecting screwing mechanism 4 is mainly composed of a steel beam anchor 41 and a connecting screw 42, and the connecting screw 42 is set outside the steel beam anchor 41 and connected with the steel beam anchor. The peripheral thread of 41 fits. The steel beam tension connector changes the assembly method of the other end, so that two adjacent steel beams 2 can be connected together, and the connecting screw 42 in the middle is rotated by a hydraulic device, and the relative movement of the anchors on both sides is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com