Novel thick coal seam slicing floor automatically laying and networking method

A layered mining and thick coal seam technology, applied in mining equipment, earthwork drilling, temporary shields, etc., can solve problems such as low networking efficiency, low networking efficiency, and poor networking effect, so as to improve networking efficiency and ensure efficient production , to avoid the effect of roof leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

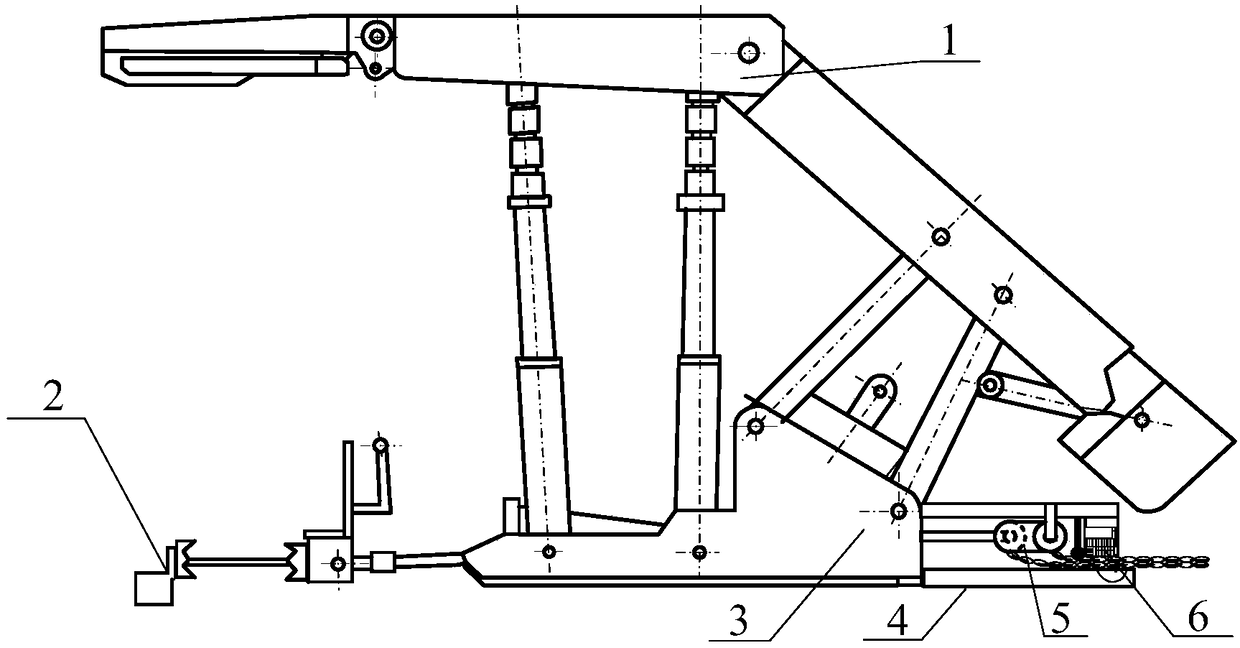

[0047] combine Figure 1 to Figure 9 , a new type of thick coal seam layered mining floor automatic laying network device, including a plurality of hydraulic supports 1, the front end of the hydraulic support is provided with a scraper conveyor 2, and the rear of the hydraulic support is provided with a support tailstock 3.

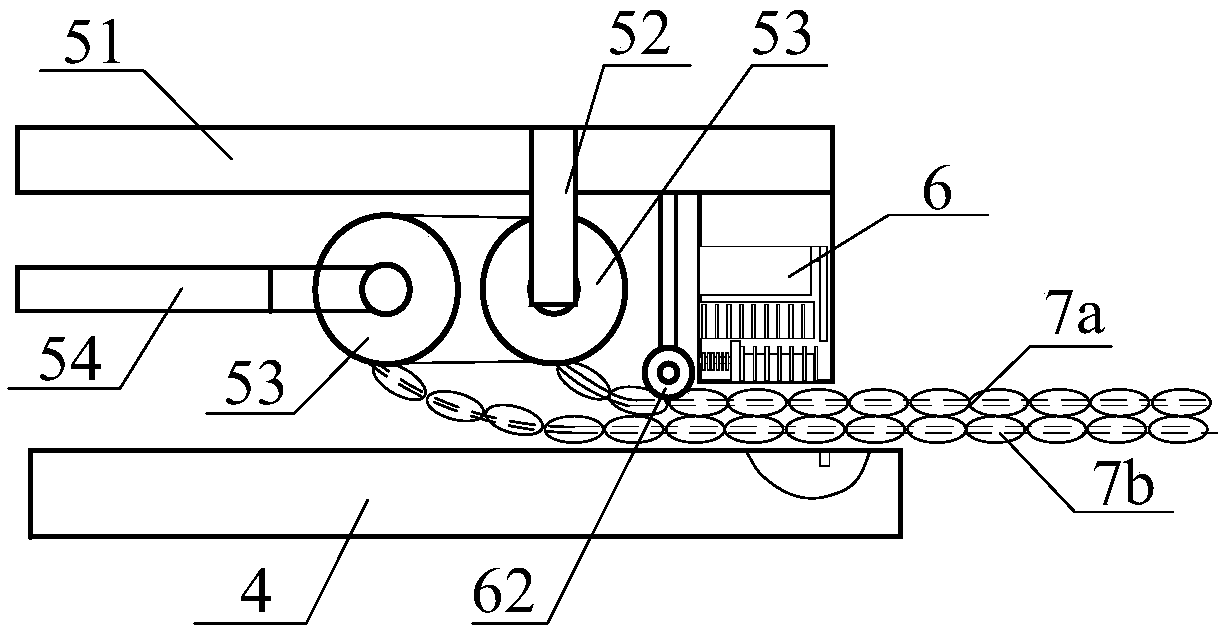

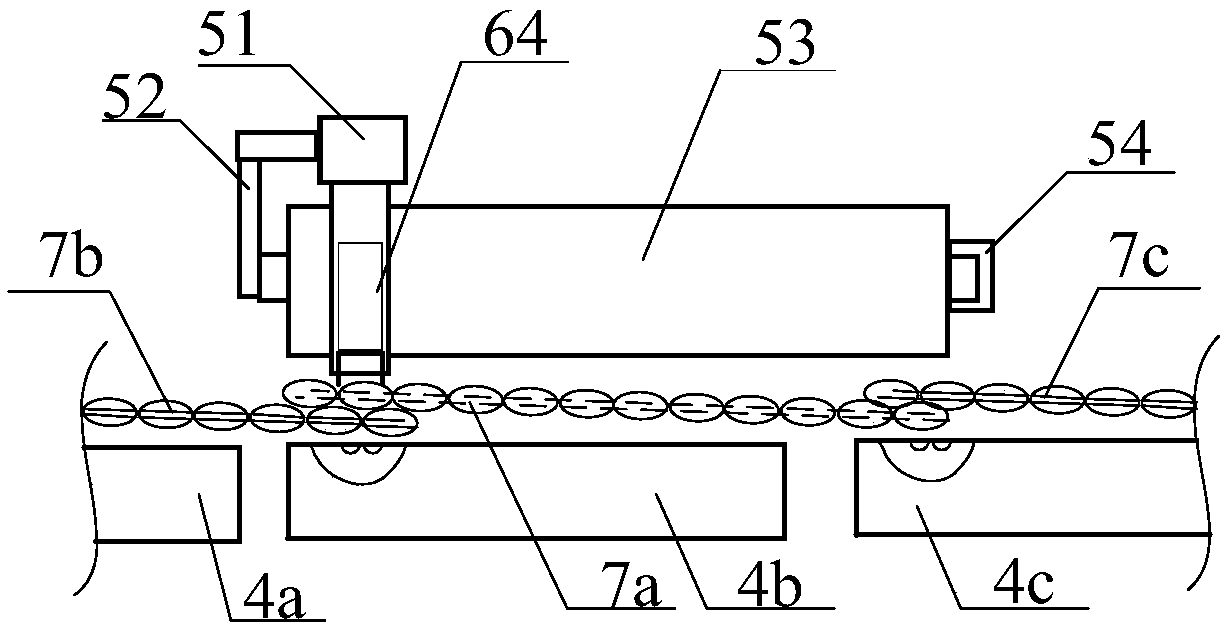

[0048] The rear part of the support tailstock 3 is connected with a support rear seat 4, and the support rear seat 4 is respectively provided with a net roll laying structure 5 and a networking structure 6, and the net roll laying structure is used for installing or spreading the wound net roll 7, The networked structure 6 is fixed on the net roll laying structure 5, and the networked structure is used for stitching and connecting the overlapped overlapping parts of the net roll to be laid and the net roll already laid. It realizes the function of automatic laying and networking of the thick coal seam layered mining floor, realizes the automatic laying an...

Embodiment 2

[0060] The method for laying a network of a novel thick coal seam layered mining floor automatic laying network device according to the above embodiment includes the following steps:

[0061] Step 1: Place the curved needle 67 on the push spring 66 to ensure the normal operation of the networking structure;

[0062] Step 2: Install the net cylinder 53 wound with the net roll on the net roll laying structure 5, specifically including:

[0063] The net roll is wound on the surface of the net cylinder, and then the net cylinder is installed between the first net cylinder arm 52 and the second net cylinder arm 54, and the net cylinder is rotated to release the net, so that the side of the net roll 7a that has been laid and the side to be paved One side of the net roll 7b is lapped and overlapped, and the lapped overlapping part 7ab is between the opening of the network box and the curved needle pit 68 to the back of the hydraulic support, and the end of the net is fixed on the net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com