Drying device applied after washing of diodes

A dehydration device and cleaning technology, which are applied in the directions of drying gas arrangement, drying solid materials, drying machines, etc., can solve the problems of inability to spin the surface of the diode, time-consuming and labor-intensive, and inconvenient operation, so as to solve the problems of incomplete dehydration, Simple structure, practical and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

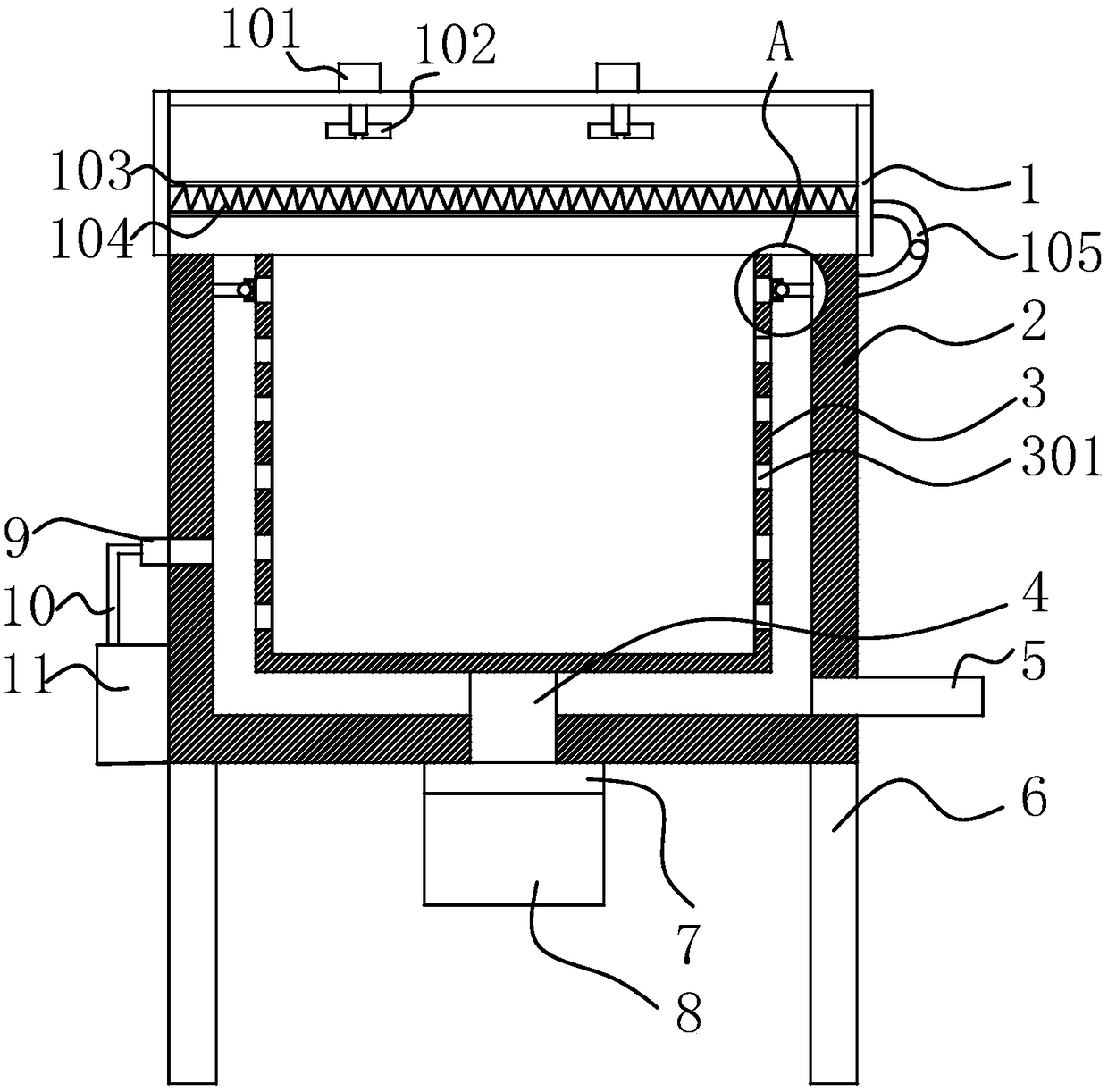

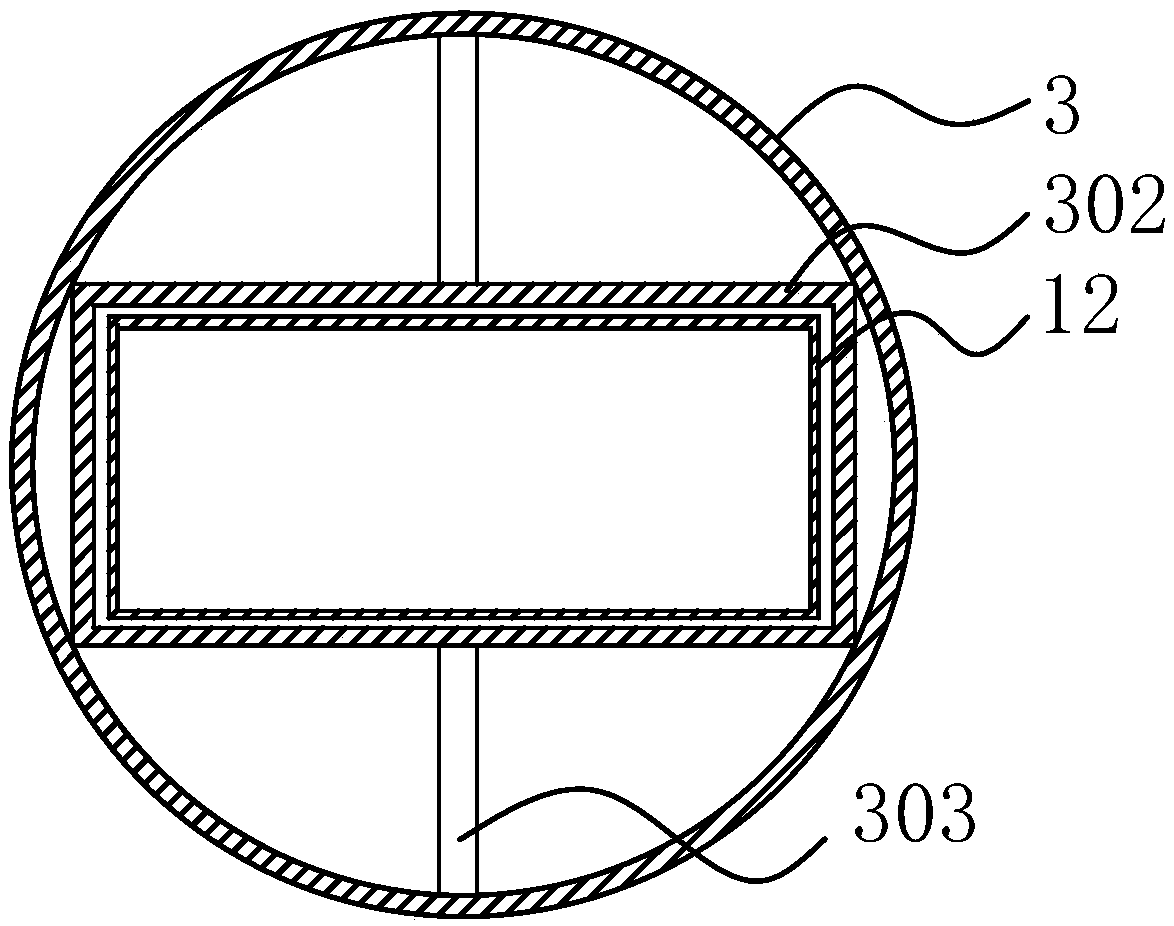

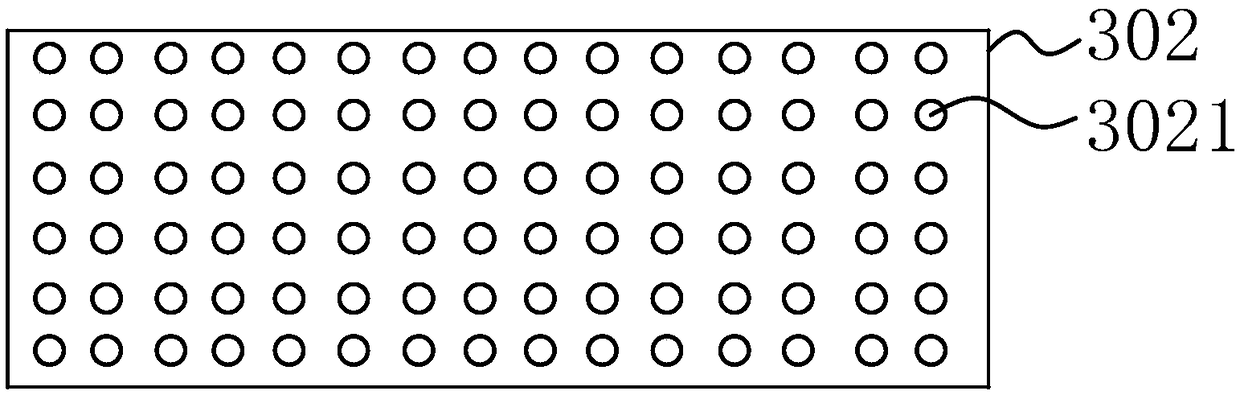

[0026] Such as figure 1 As shown, the present invention provides a dehydration device after diode cleaning, which includes a housing 2, a drum 3 disposed in the housing 2, and a cover 1 disposed on the housing 2, and is characterized in that the cover 1 passes through C A type hinge 105 is connected with the housing 2, the top of the cover 1 is provided with a first motor 101, the output end of the first motor 101 passes through the cover 1 and the end is provided with a fan blade 102, and the inner wall of the cover 1 is provided with a protective cover 103 , the protective cover 103 is provided with an electric heating wire 104, the surface of the rotating drum 3 is uniformly arranged with water leaks 301, the bottom of the rotating drum 3 is fixed with a rotating shaft 4, and the rotating shaft 4 is connected to the bottom of the housing 2 through a coupling 7. The second motor 8 is rotationally connected, one side of the housing 2 is provided with a water outlet 5, and the...

Embodiment 2

[0030] Such as figure 1 As shown, the present invention provides a dehydration device after diode cleaning, which includes a housing 2, a drum 3 disposed in the housing 2, and a cover 1 disposed on the housing 2, and is characterized in that the cover 1 passes through C A type hinge 105 is connected with the housing 2, the top of the cover 1 is provided with a first motor 101, the output end of the first motor 101 passes through the cover 1 and the end is provided with a fan blade 102, and the inner wall of the cover 1 is provided with a protective cover 103 , the protective cover 103 is provided with an electric heating wire 104, the surface of the rotating drum 3 is uniformly arranged with water leaks 301, the bottom of the rotating drum 3 is fixed with a rotating shaft 4, and the rotating shaft 4 is connected to the bottom of the housing 2 through a coupling 7. The second motor 8 is rotationally connected, one side of the housing 2 is provided with a water outlet 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com