Positive pressure leak hole calibration system and method with lower limit of 10<-10>Pam<3>/s

A calibration system and positive pressure leak technology, which is applied in the testing of machine/structural components, fluid tightness testing, and detection of fluid appearance at the leak point, etc., can solve the problems that cannot meet the calibration requirements of positive pressure leaks, etc. , to achieve the effect of solving calibration technical problems and technical bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

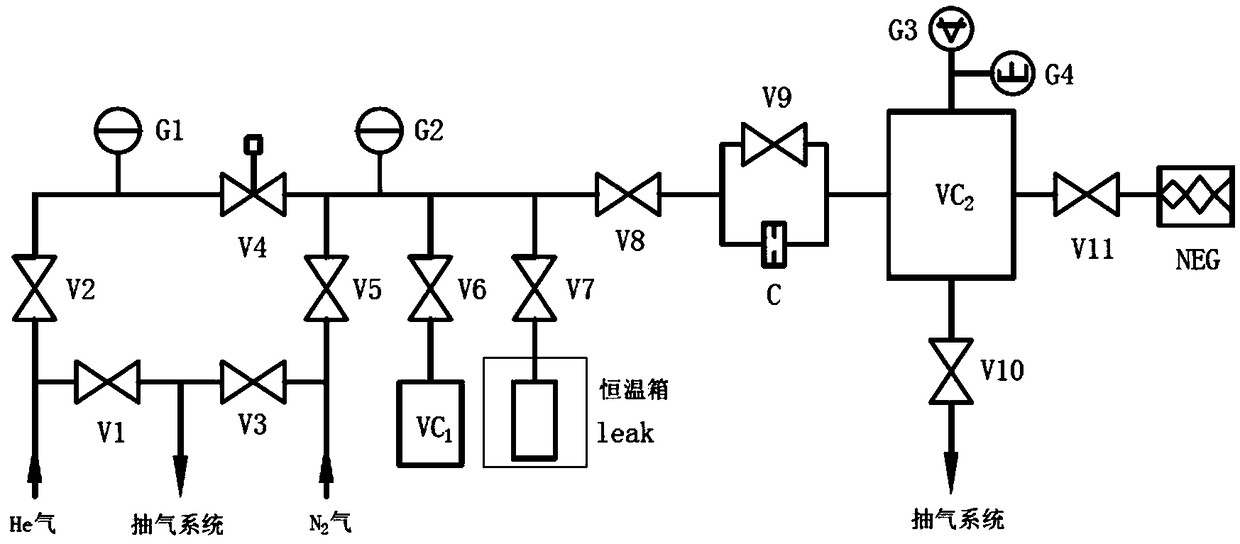

[0040] (1) Keep the ambient temperature at 23±1°C, use high-purity N 2 Gas (both with a purity of 99.999%) washes the vacuum system 3 times; after that, through the valve V 5 Charge 101.32kPa of N to the Leak outlet of the calibrated leak 2 Gas (99.999% pure) is used to simulate the ground atmospheric pressure state at the leak outlet.

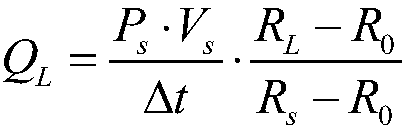

[0041] (2) Set the temperature of the incubator to 23±0.05°C, close the valve V 7 The gas leaked from the leak hole is accumulated in the accumulation chamber (Leak and V 7 Between the metal seal structure, the volume is V s =0.98mL), after accumulating the leaked gas for 36000s, the accumulative indoor gas pressure is 218Pa(P s =218Pa), open the valve V 7 Expand the mixed gas in the accumulation chamber to VC 1 Decaying pressure in the volume composed of its related pipes, after waiting for 100s, close the valve V 9 , open the valve V 8 , the mixed gas is introduced into the mass spectrometry chamber VC through the molecular flow samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com