A production process for infiltrating graphene into a magnetic body

A production process and magnetic body technology, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of shortening the service life of magnets, poor high-temperature resistance of magnets, and demagnetization of magnets, so as to improve high-temperature resistance. The effect of prolonging the service life and avoiding demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

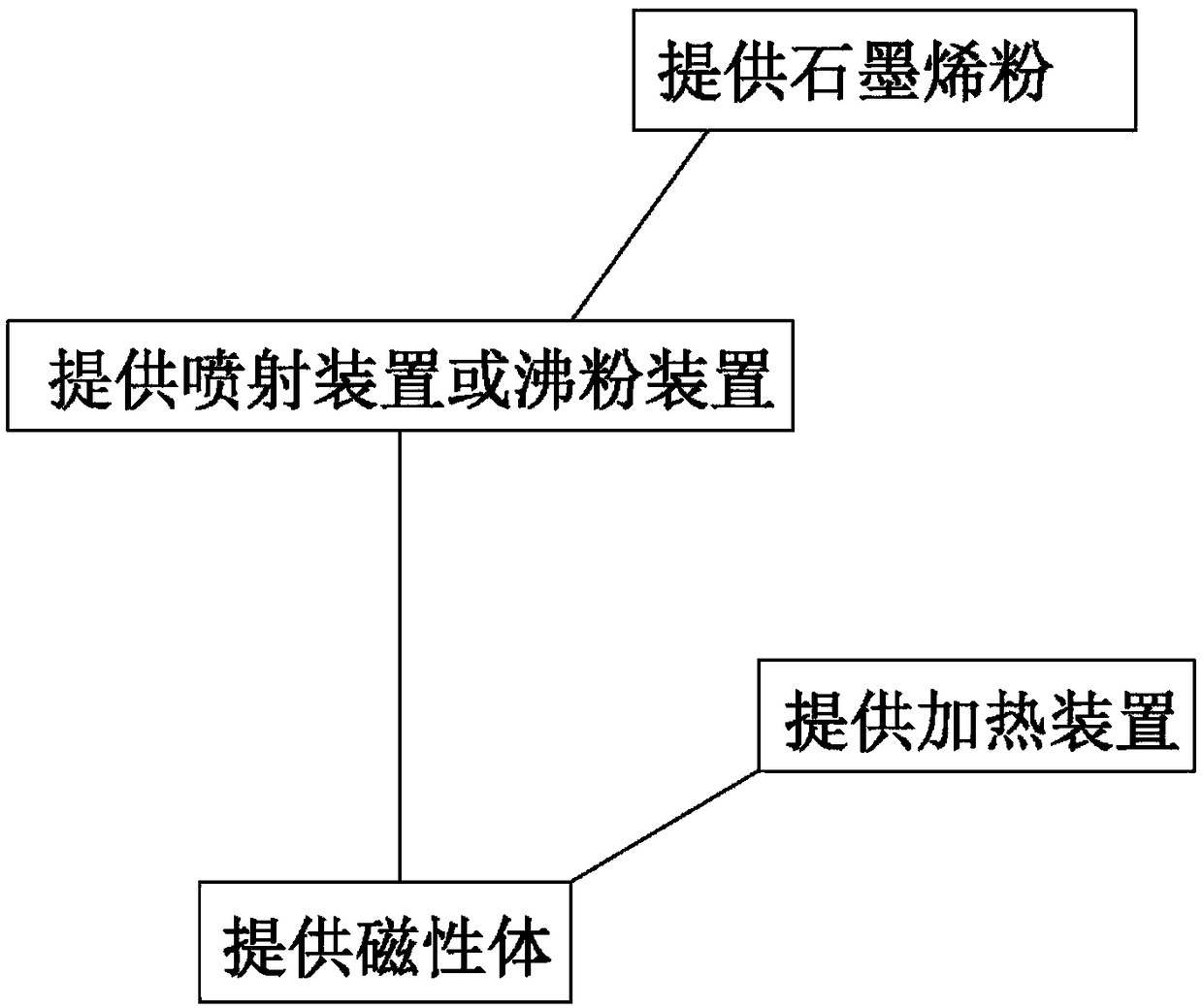

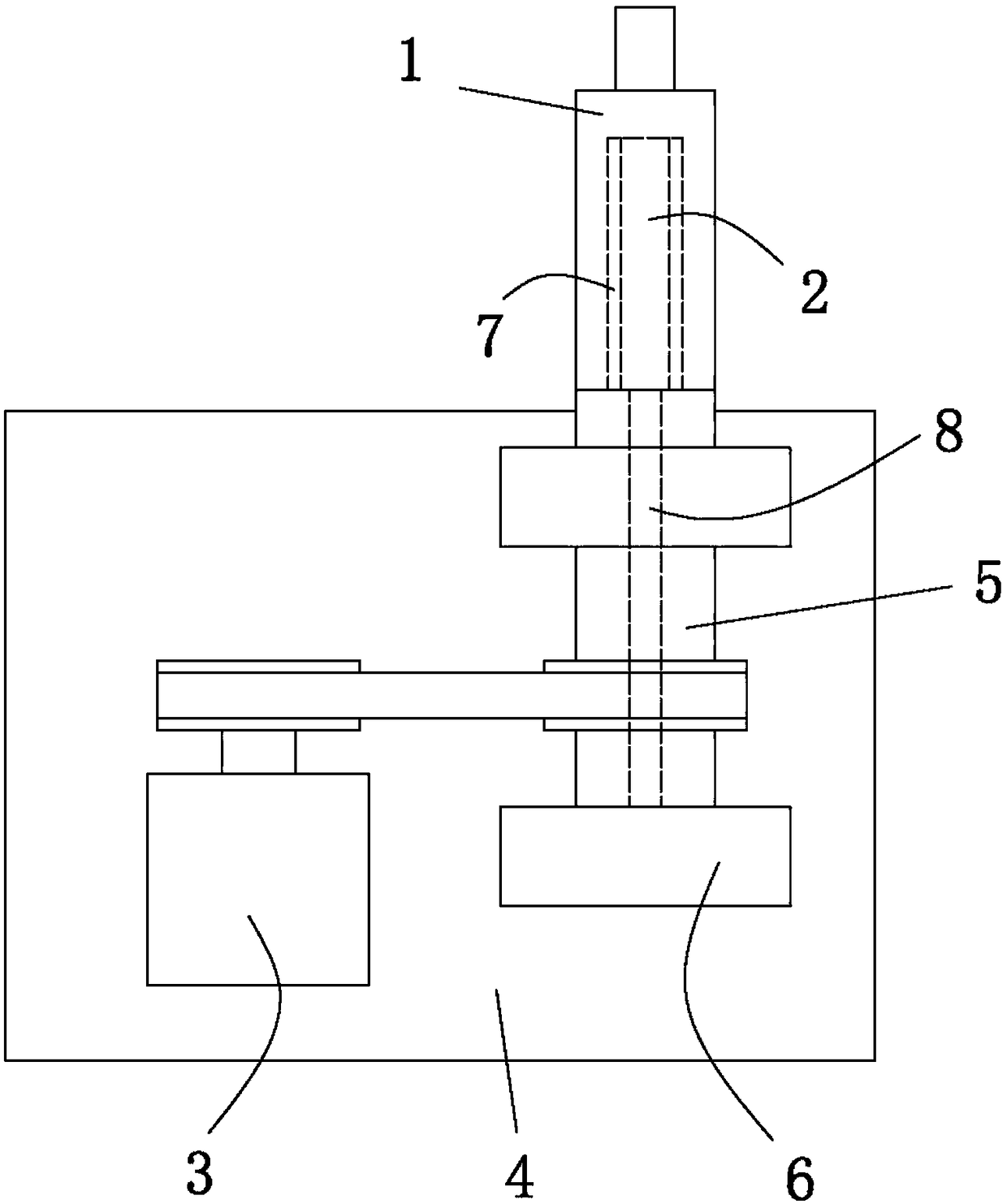

[0038] see figure 1 , figure 2 , image 3 and Image 6 Shown, a kind of graphene of the present invention infiltrates the production technique of magnetic body, and the production technique of described graphene infiltration magnetic body comprises:

[0039] A magnetic body 101 is provided, and the magnetic body 101 is made of a magnetic material, for example, the magnetic body 101 is made of a material containing iron, cobalt or nickel, or the magnetic body 101 is made of a material containing NdFeB;

[0040] A heating device is provided, and the heating device is used to heat the magnetic body 101 to make the molecular movement of the magnetic body 101 more active;

[0041] Graphene powder is provided, and the graphene powder is composed of nanoscale graphene particles 102;

[0042] An injection device is provided, and the injection device is used to spray and infiltrate the graphene powder into the magnetic body 101 heated by the heating device. After the heating devic...

Embodiment 2

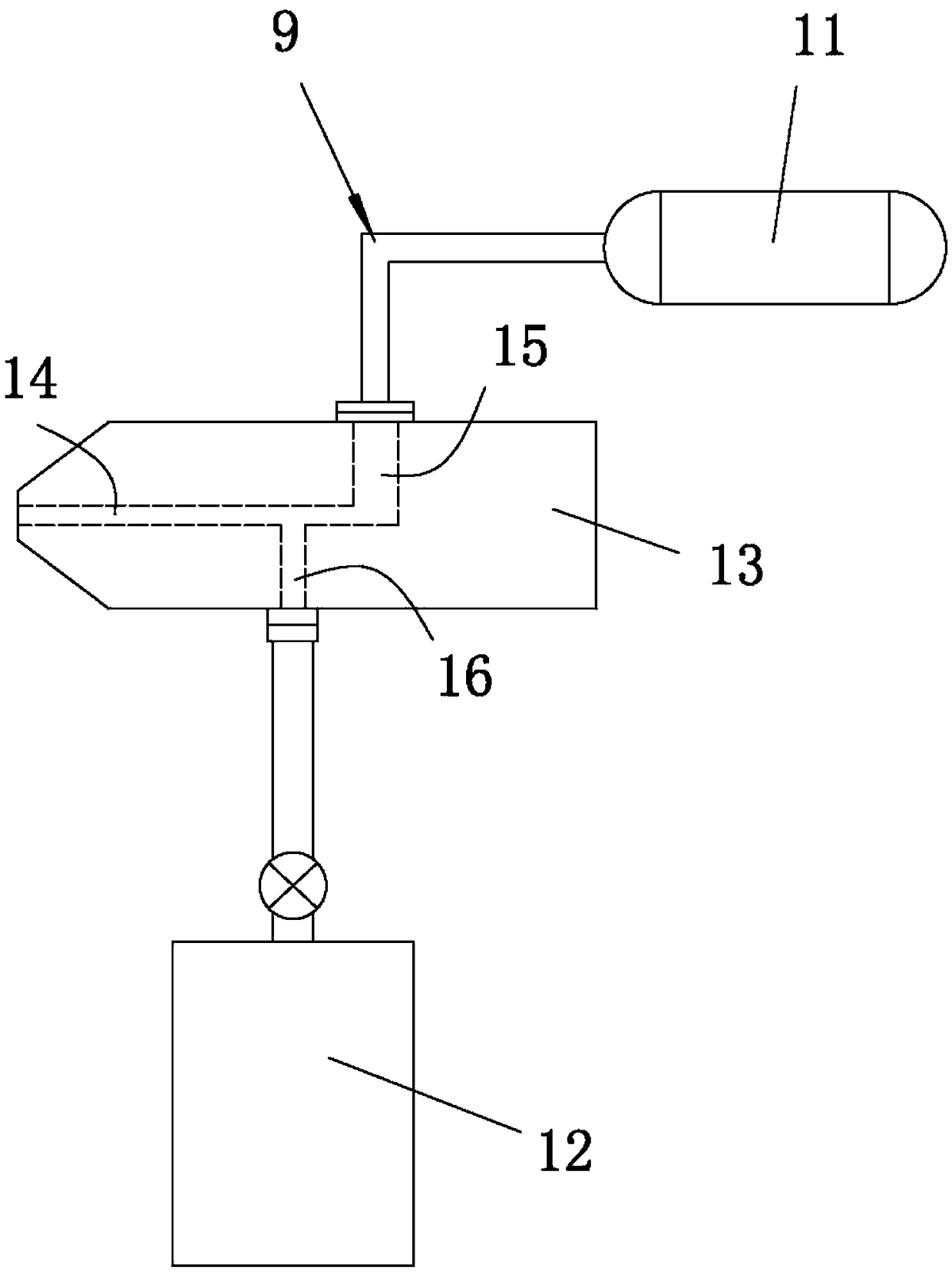

[0050] see figure 1 , Figure 4 , Figure 5 and Image 6 As shown, a powder boiling device 17 is provided, and the powder boiling device 17 includes a material holding cylinder 18, an air pump 19 and an equalizing plate 21 positioned in the material containing barrel 18. The equalizing plate 21 is a prior art, and the equalizing plate 21 is provided with a uniform A plurality of equalizing holes, the equalizing plate 21 divides the container 18 into a material chamber 22 and a material chamber 23, in this embodiment, the material chamber 23 is located above the material chamber 22, and the equalizing plate 21 roughly It is in the shape of a flat plate, and the flow equalizer 21 is located between the material chamber 23 and the material chamber 22. The material chamber 22 is used to accommodate graphene powder, and the heat conducting rod 1 is rotated and set in the material chamber 23 through the heat insulating column 5. The container chamber 23 is used to accommodate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com