A metal package rectifier diode and a manufacturing method thereof

A rectifier diode and metal packaging technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as low reliability and low product quality, and achieve strong heat dissipation, fast sintering, and good adhesion. moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

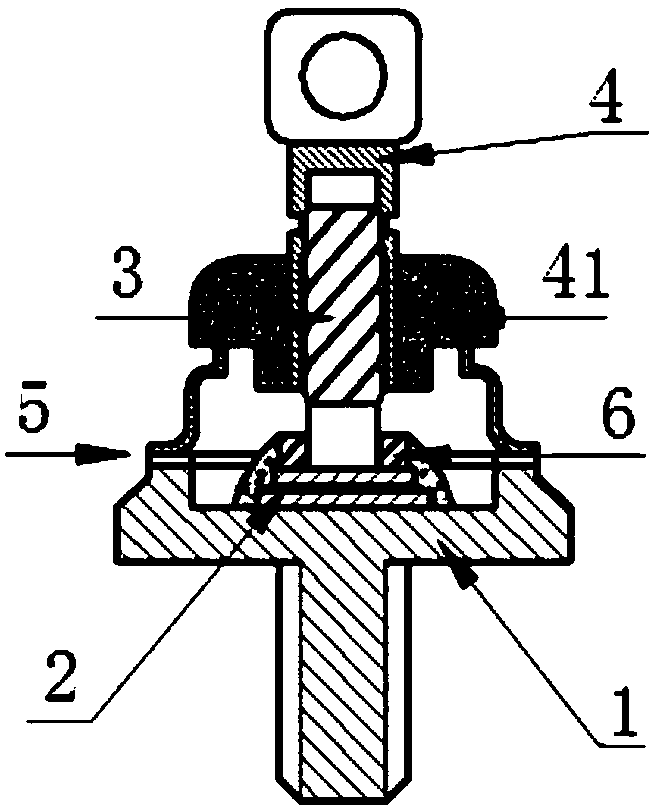

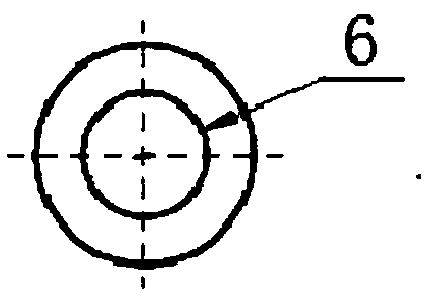

[0031] A metal package rectifier diode of the present invention, such as Figure 1-Figure 5 As shown, it includes a tube base 1, a tube core assembly 2, a lead column 3 and a tube cap 4; the tube base 1 and the tube cap 4 respectively form the first and second electrodes, and the tube core assembly 2 is welded on the tube base 1, and the lead wire One end of the post 3 is welded on the tube core assembly 2, and the other end is fixedly connected to the cap 4; the lead post 3 is arranged through the cap 4, and the cap 4 is respectively sealed and connected to the stem 1 and the lead post 3; the lead post 3 is formed by weaving multiple strands of metal wires 31, and the two ends are provided with metal sleeves 32 for fastening the metal wires.

[0032] Wherein, one end of the lead post 3 weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com