A water-cooled plate and a water-cooled battery

A technology of water-cooled plate and first flow channel, which is applied to secondary batteries, circuits, electrical components, etc., can solve the problems of battery performance degradation, large temperature difference of battery cells, and shortened battery life, so as to eliminate temperature difference and achieve consistent cooling effect. The effect of improving battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

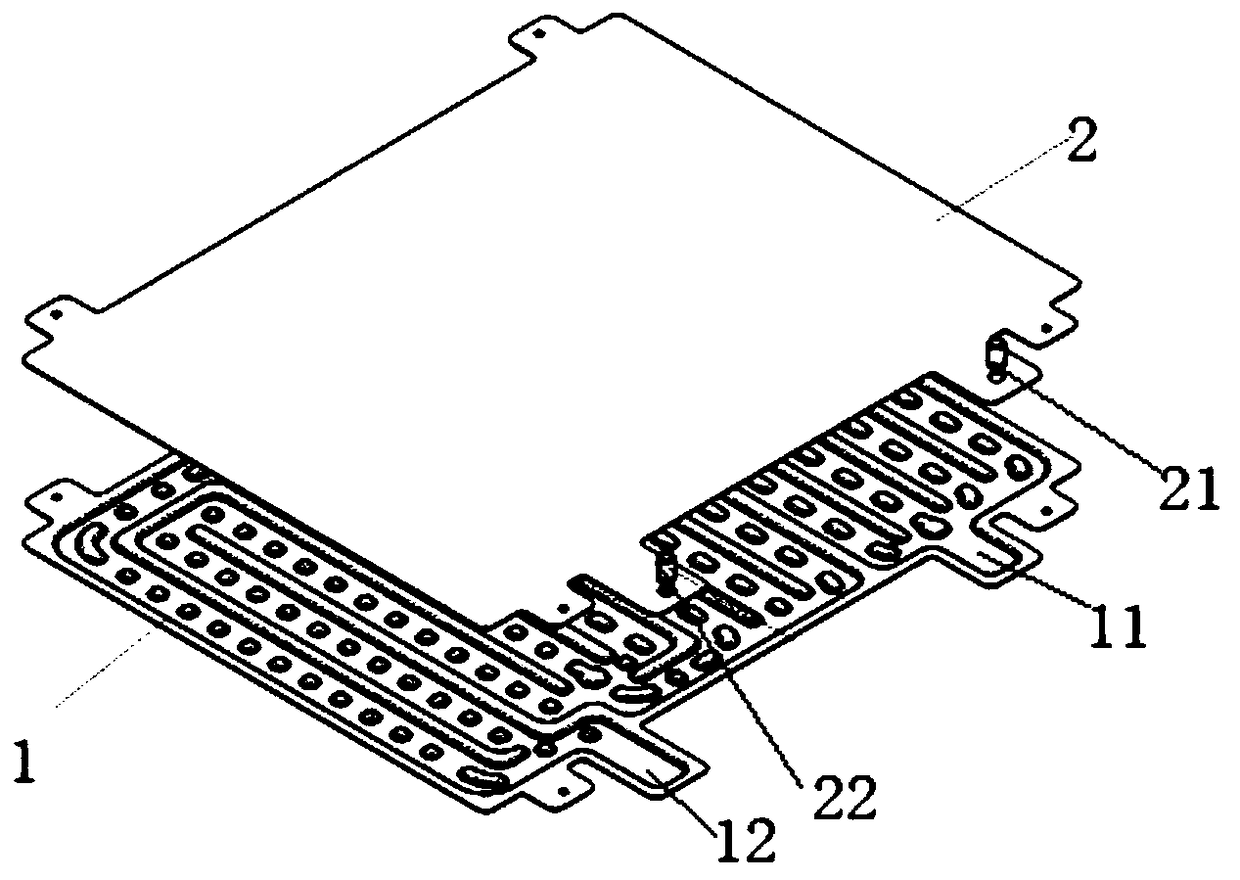

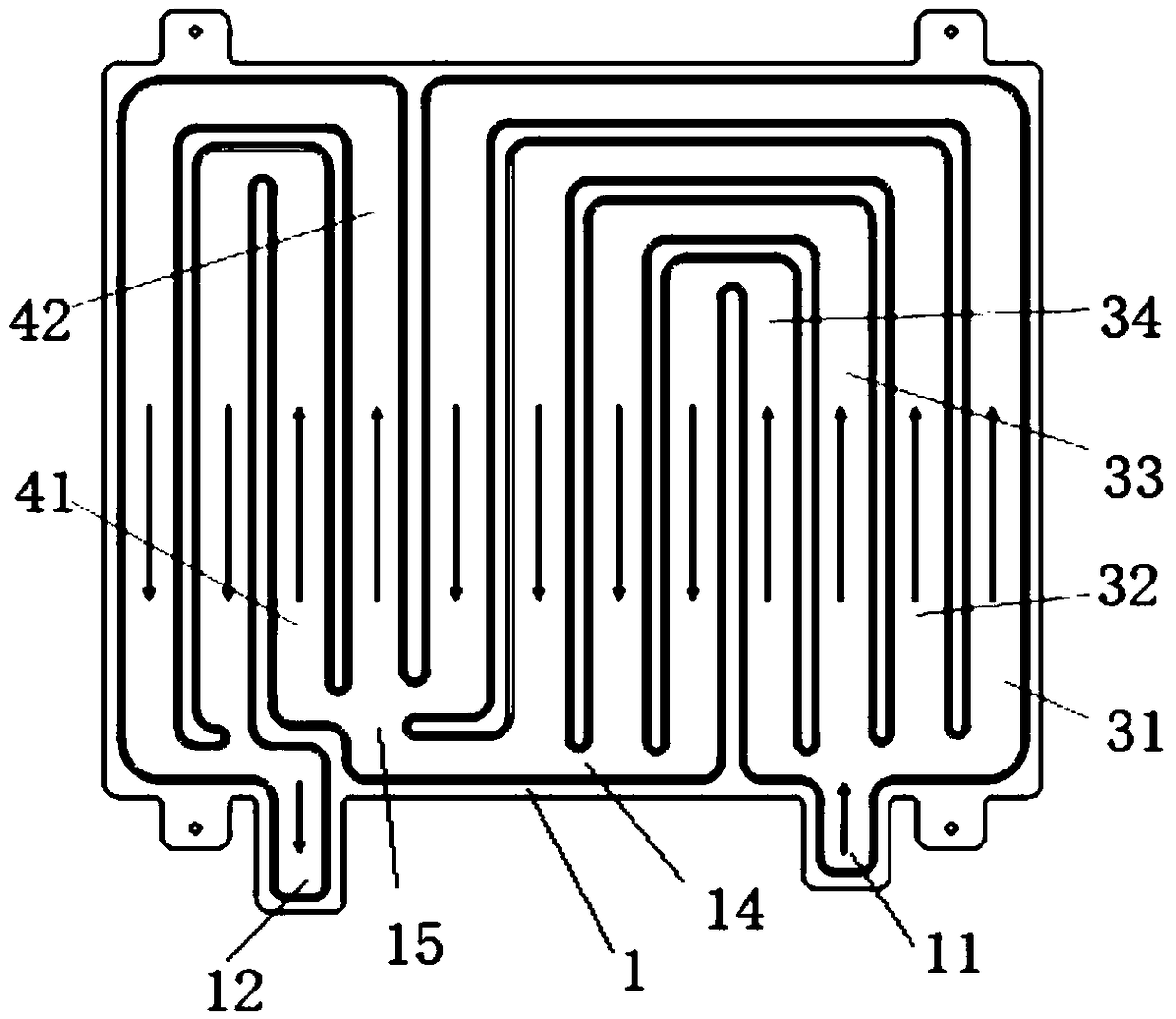

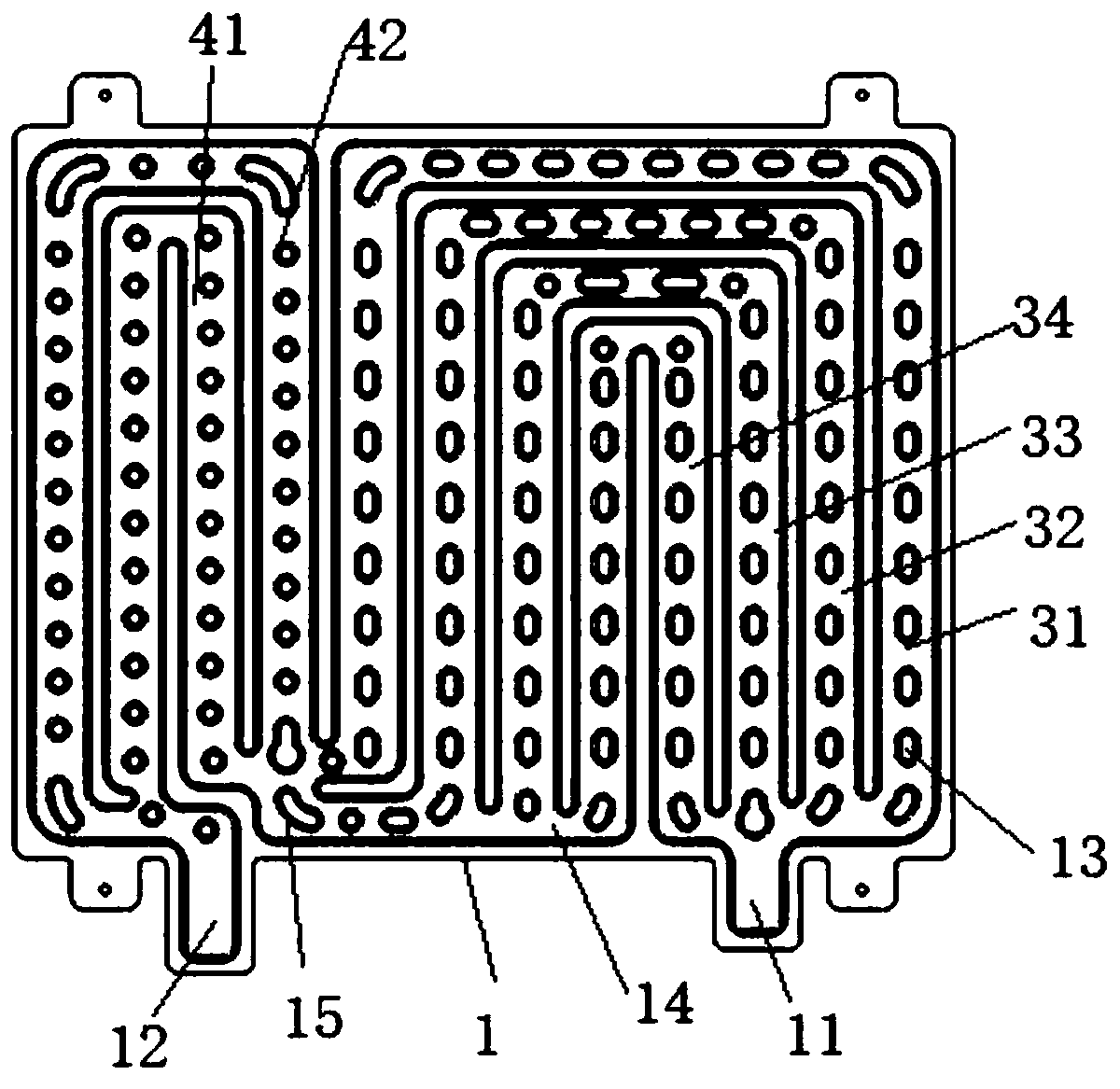

[0028] This embodiment provides a water-cooled plate, such as Figure 1-3 , including a base plate 1 and a cover plate 2, a groove is provided on the base plate 1, and the cover plate 2 is welded on the base plate 1, and an accommodation cavity is formed between the groove on the base plate 1 and the cover plate 2, and the accommodation cavity There are flow passages for coolant circulation. In this embodiment, four first flow channels 31, 32, 33, 34 are arranged in parallel in the front end area (water inlet area) of the substrate 1, and two second flow channels 41, 34 are arranged in parallel in the rear end area (water outlet area). 42. The sum of the cross-sectional areas of the four first flow channels 31, 32, 33, 34 is greater than the sum of the cross-sectional areas of the two second flow channels 41, 42. When flowing to the second flow passages 41, 42, due to the reduced cross-section, the flow velocity of the cooling liquid in the second flow passages 41, 42 is grea...

Embodiment 2

[0034] On the basis of Embodiment 1, this embodiment provides a water-cooled battery, such as Figure 4 A mounting hole is provided at the four corners of the water cooling plate, and the water cooling plate is fixed on the crossbeam of the lower box of the battery pack through bolts at the mounting holes. Among them, an insulating heat conduction pad 7 is provided between the cover plate 2 of the water-cooled plate and the battery module 5. When the thermal management system is turned on, the heat of the high-temperature battery is quickly transferred to the water-cooled plate through the heat-insulated heat conduction pad 7, and the coolant flows from the The liquid joint 21 flows in, passes through the first flow channel 31, 32, 33, 34 and the second flow channel 41, 42, and then flows out from the liquid outlet joint 22, taking away the heat generated by the battery module 5, and completing the cooling of the battery. After flowing out from the liquid outlet joint 22, it e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com