A composite optical fiber communication system based on PROFIBUS bus

An optical fiber communication system and bus technology, applied in the direction of optical fiber transmission, transmission system, bus network, etc., can solve problems such as unstable communication signal transmission, and achieve the effects of easy troubleshooting, high reliability, and light burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

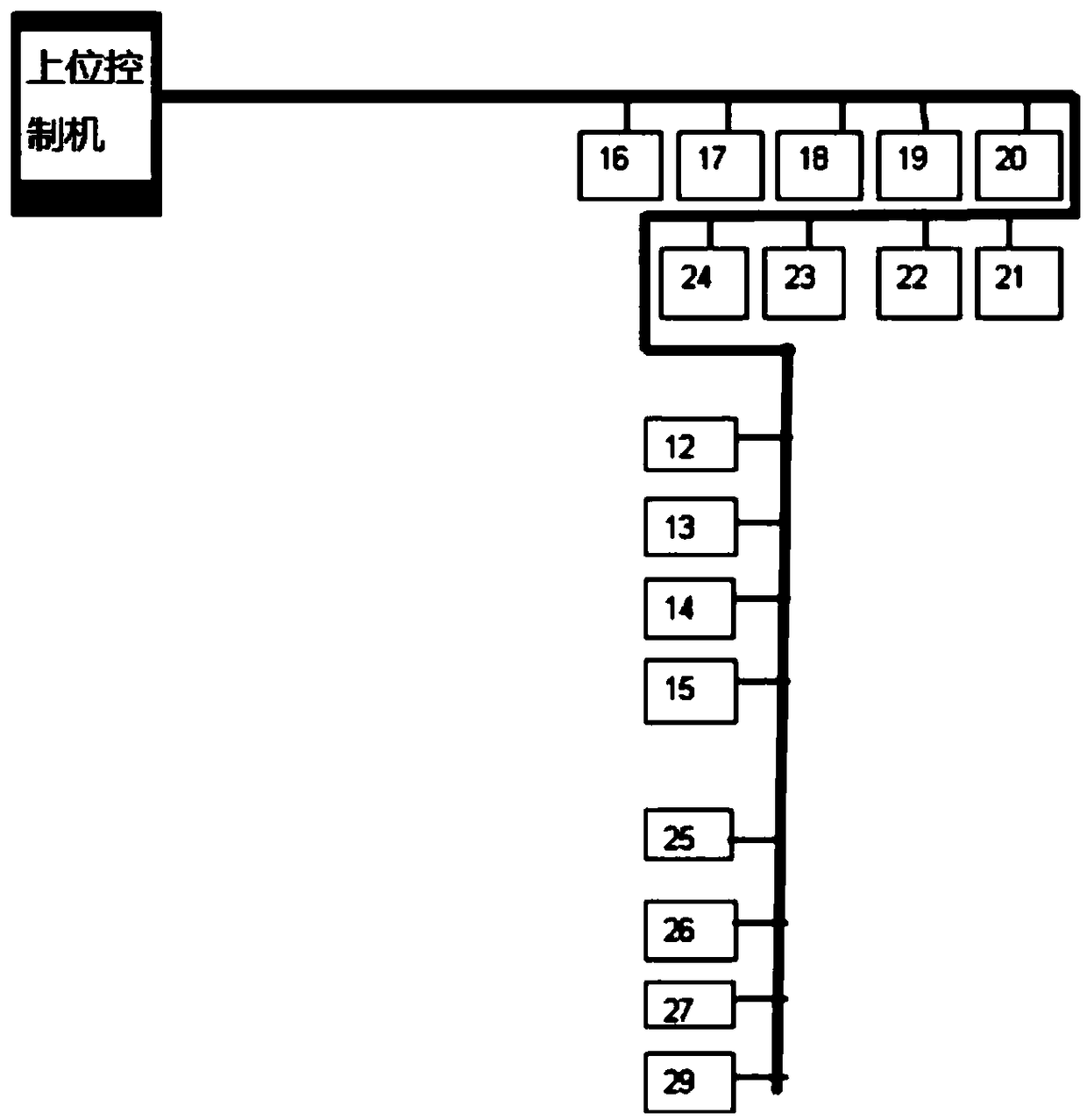

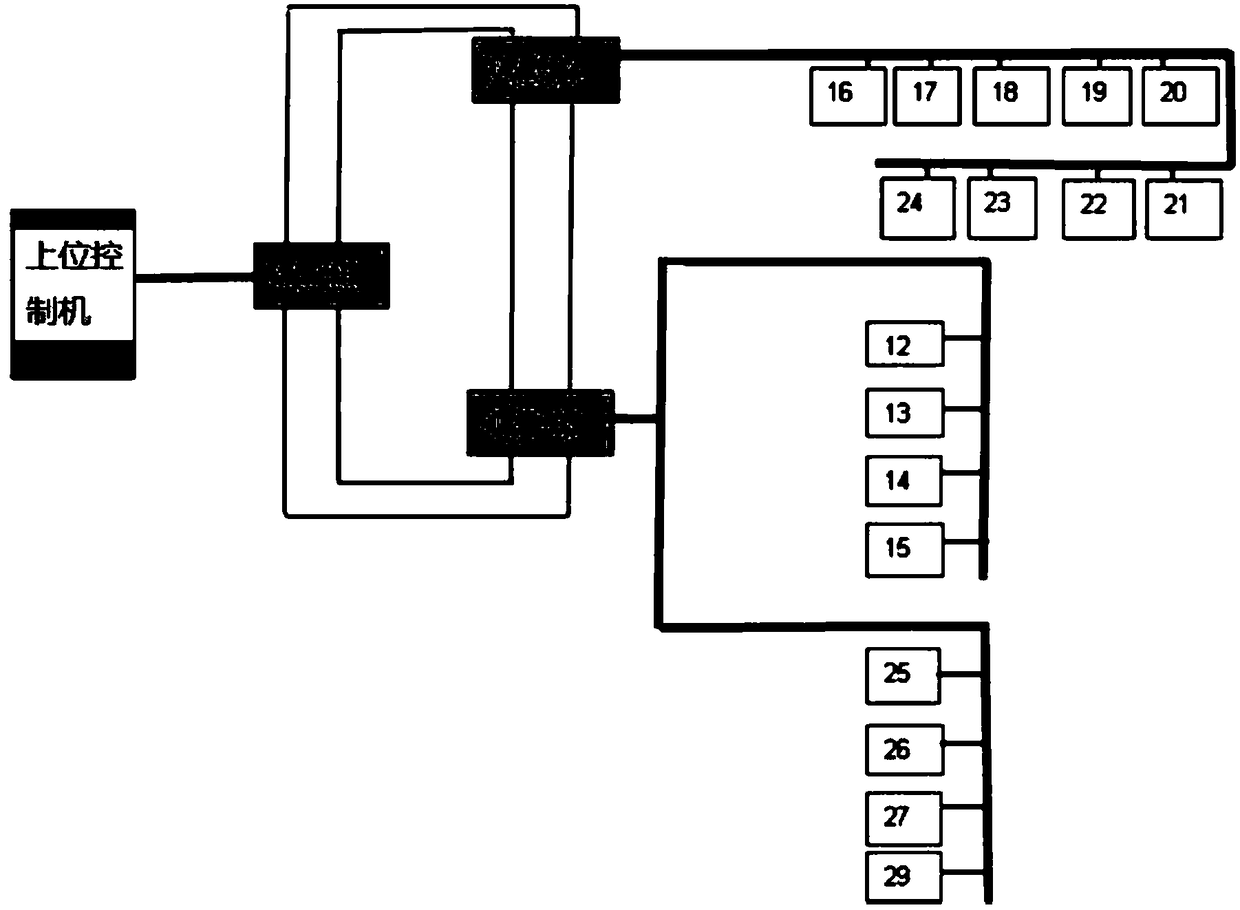

[0036] Please refer to Figure 3 to Figure 4 , in the first embodiment of the present invention, the composite optical fiber communication system based on the PROFIBUS bus includes: a host controller, a photoelectric conversion module and a plurality of transmission control points; wherein the photoelectric conversion module includes at least three photoelectric conversion modules, They are: the first photoelectric conversion module OLM-01, the second photoelectric conversion module OLM-02, and the third photoelectric conversion module OLM-03. The signal input terminal of the first photoelectric conversion module OLM-01 is connected to the host controller, and the signal output terminal of the first photoelectric conversion module OLM-01 is used to connect the signal input terminal of the second photoelectric conversion module OLM-02 and the third photoelectric conversion module respectively. The signal input terminal of the module OLM-03, the signal output terminal of the sec...

no. 2 example

[0044] Based on the previous embodiment, the PROFIBUS-based composite optical fiber communication system provided by the second embodiment of the present application includes: a host controller, a photoelectric conversion module and a plurality of transmission control points; wherein the photoelectric conversion module includes: the first The photoelectric conversion module OLM-01, the second photoelectric conversion module OLM-02, the third photoelectric conversion module OLM-03 and the fourth photoelectric conversion module OLM-04. The signal input end of the first photoelectric conversion module OLM-01 is connected to the host controller, and the signal output end of the first photoelectric conversion module OLM-01 is respectively connected to the signal input end of the second photoelectric conversion module OLM-02, the third photoelectric conversion module OLM The signal input terminal of -03 and the signal input terminal of the fourth photoelectric conversion module OLM-0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com