Reinforcing material, and preparation method and application thereof in preparation of thermosensitive film

A technology of reinforcing material and heat-sensitive film, applied in the direction of coating, etc., can solve the problem of low bonding strength of heat-sensitive film, and achieve the effect of easy batch production, low energy consumption and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Preparation of La 0.6 Sr 0.4 MnO 3 Sol, 4.37 grams of lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), 1.42 grams of strontium nitrate (Sr(NO 3 ) 2 ), 4.21 grams of manganese nitrate (Mn(NO 3 ) 2 4H 2 O) Mix and dissolve in deionized water to obtain a solution, add citric acid-ethylene glycol solution, stir to form a sol and continue to stir for 0.5 hours to obtain La 0.6 Sr 0.4 MnO 3 Sol; the ratio of the amount of metal cation in the solution to the amount of citric acid is 1:1, and in the citric acid-ethylene glycol solution, the ratio of the amount of matter between citric acid and ethylene glycol is 1:2;

[0030] 2) Preparation of La 0.6 Sr 0.4 MnO 3 Gel, the sol prepared in step 1) was heated and stirred at 60°C until viscous, and then dried at 60°C for 12 hours to obtain La 0.6 Sr 0.4 MnO 3 gel;

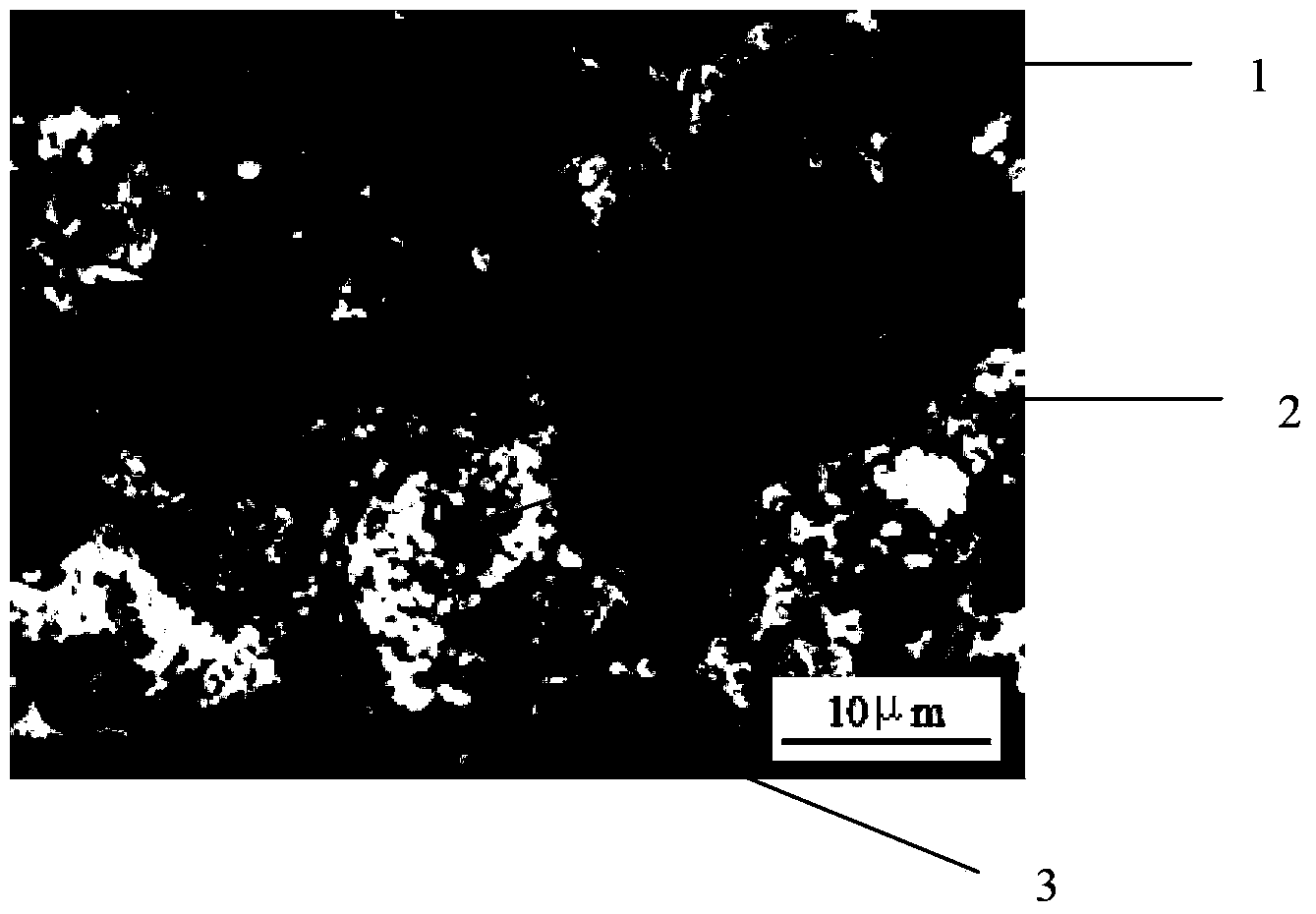

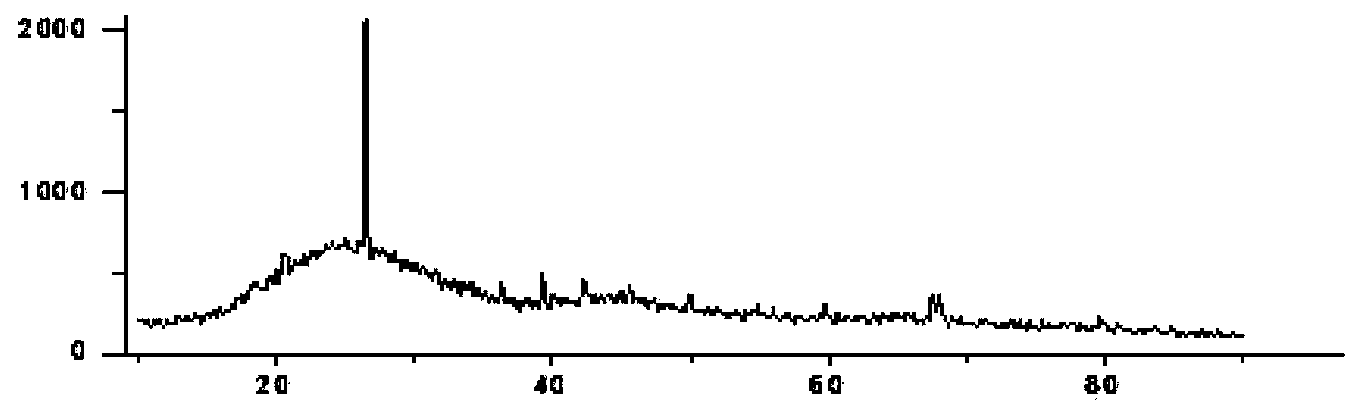

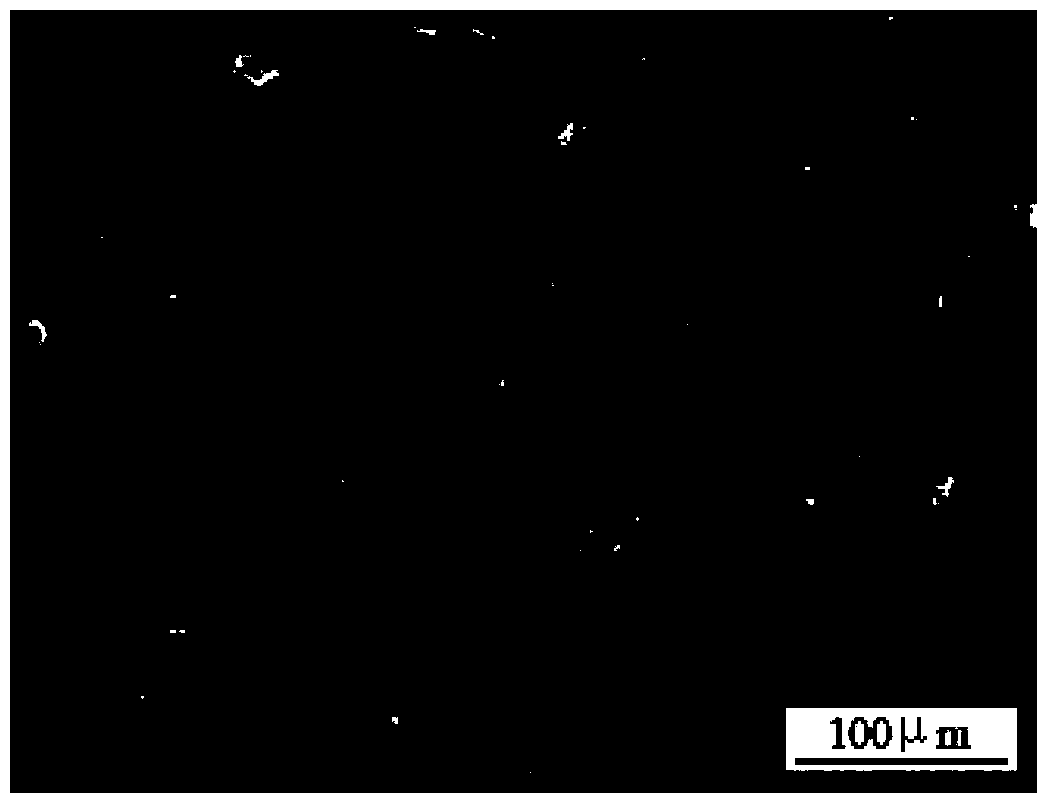

[0031] 3) Preparation of La 1-x Sr x MnO 3 Powder, the La prepared in step 2) 0.6 Sr 0.4 MnO 3 The gel was calcined at 600 °C for 1 hour, and then th...

Embodiment 2

[0037] 1) Preparation of LaMnO 3 Sol, according to the molar ratio La:Mn=1:1, mix and dissolve lanthanum nitrate and manganese nitrate in deionized water to obtain a solution, add citric acid-ethylene glycol solution, stir to form a sol and continue to stir for 0.5 hours to obtain LaMnO 3 Sol; the ratio of the amount of metal cation in the solution to the amount of citric acid is 1:1, and in the citric acid-ethylene glycol solution, the ratio of the amount of matter between citric acid and ethylene glycol is 1:2;

[0038] 2) Preparation of LaMnO 3 Gel, the sol prepared in step 1) was heated and stirred at 60°C until viscous, and then dried at 60°C for 12 hours to obtain La 0.6 Sr 0.4 MnO 3 gel;

[0039] 3) Preparation of La 1-x Sr x MnO 3 Powder, the LaMnO prepared in step 2) 3 The gel was calcined at 600 °C for 1 hour, and then the calcined product was ground for 10 minutes to obtain LaMnO 3 Powder;

[0040] 4) Prepare pure low melting point phase powder, mix 1.52g ...

Embodiment 3

[0045] 1) Preparation of La 0.2 Ca 0.8 FeO 3 Sol, according to the ratio of the amount of substances La: Ca: Fe = 0.2: 0.8: 1, mix and dissolve 1.27g of lanthanum nitrate, 2.78g of calcium nitrate, and 5.95g of ferric nitrate in deionized water to obtain a solution, add citric acid-ethylene glycol solution, stirred to form a sol and continued to stir for 3 hours to obtain La 0.6 Sr 0.4 FeO 3 Sol, the ratio of the amount of metal cations in the solution to the amount of citric acid is 1:3, and in the citric acid-ethylene glycol solution, the ratio of the amount of matter between citric acid and ethylene glycol is 1:6;

[0046] 2) Preparation of La 0.6 Sr 0.4 FeO 3 Gel, the sol prepared in step 1) was heated and stirred at 90°C until viscous, and then left to dry at 60°C for 12 hours to obtain La 0.6 Sr 0.4 FeO 3 Gel; the gel was calcined at 800°C for 1 hour, and then the calcined product was ground for 10 minutes to obtain La 0.6 Sr 0.4 FeO 3 Powder;

[0047] 3) P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com