Construction method of high tibial osteotomy guide plate model

A construction method and guide plate technology, applied in bone drill guidance, medical science, surgery, etc., can solve the problems of increased operation time, inability to ensure accurate planning, and increased radiation doses of doctors and patients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] Another aspect of the present invention provides a method for preparing a personalized high tibial osteotomy guide plate, the method comprising: constructing an obtained high tibial osteotomy guide plate model according to the construction method of the high tibial high osteotomy guide plate model, and preparing a personalized High tibial osteotomy guide. According to the method for constructing the high tibial osteotomy template model, the method of constructing the high tibial osteotomy template and preparing the personalized high tibial osteotomy template should be known to those skilled in the art, for example, 3D can be used For methods such as printing, the material used may be photosensitive resin or the like.

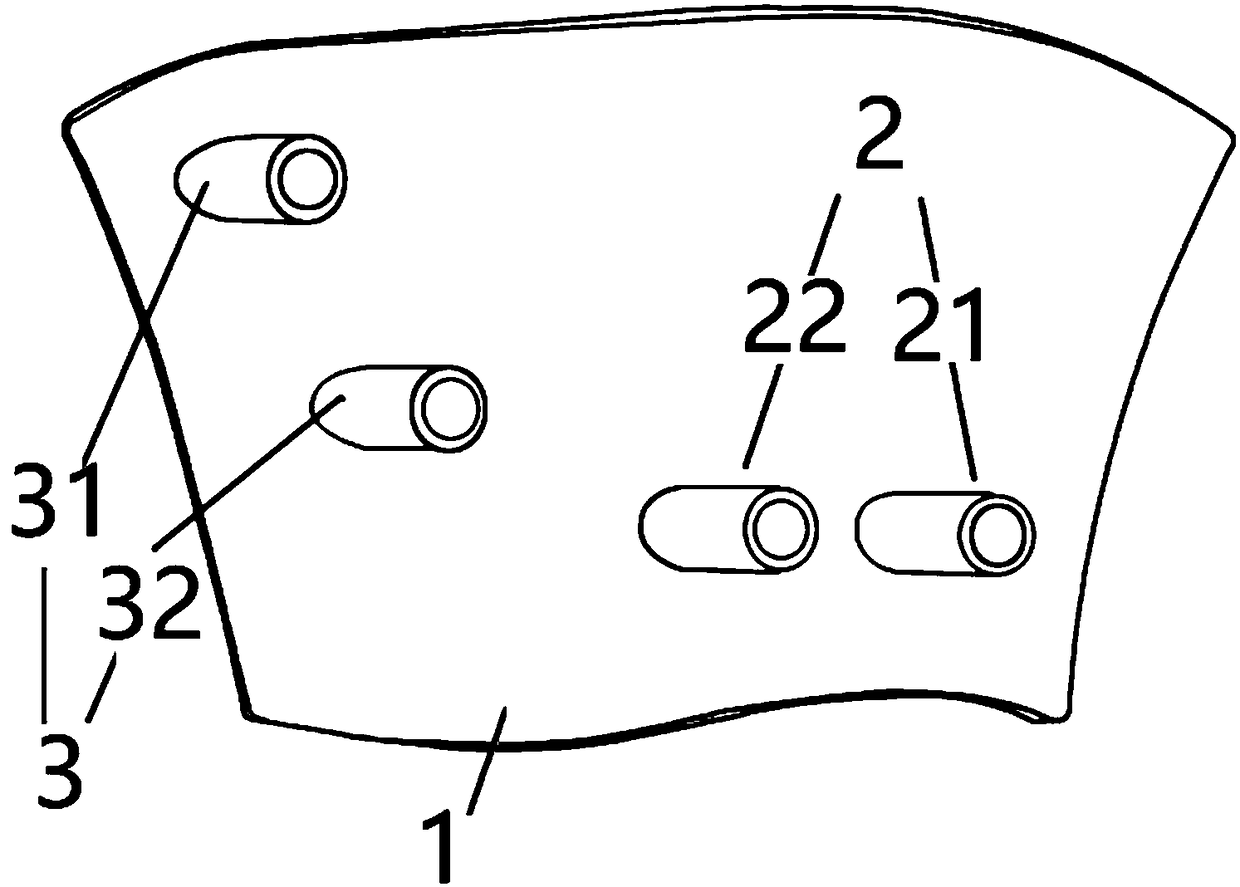

[0085] Another aspect of the present invention provides a personalized high tibial osteotomy guide plate. The personalized high tibial osteotomy guide can be obtained by constructing the high tibial osteotomy model described above, or prepared by the pre...

Embodiment 1

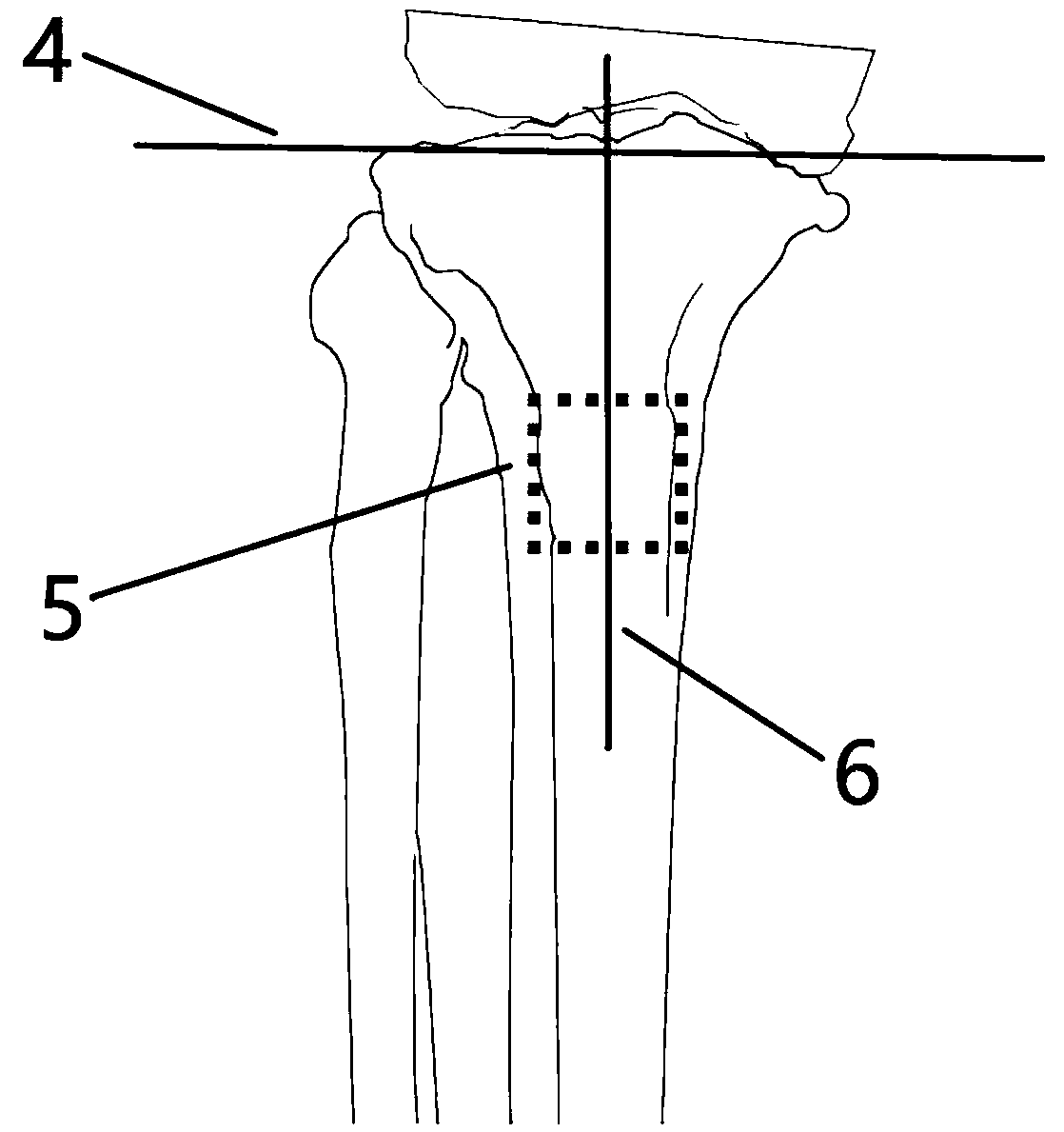

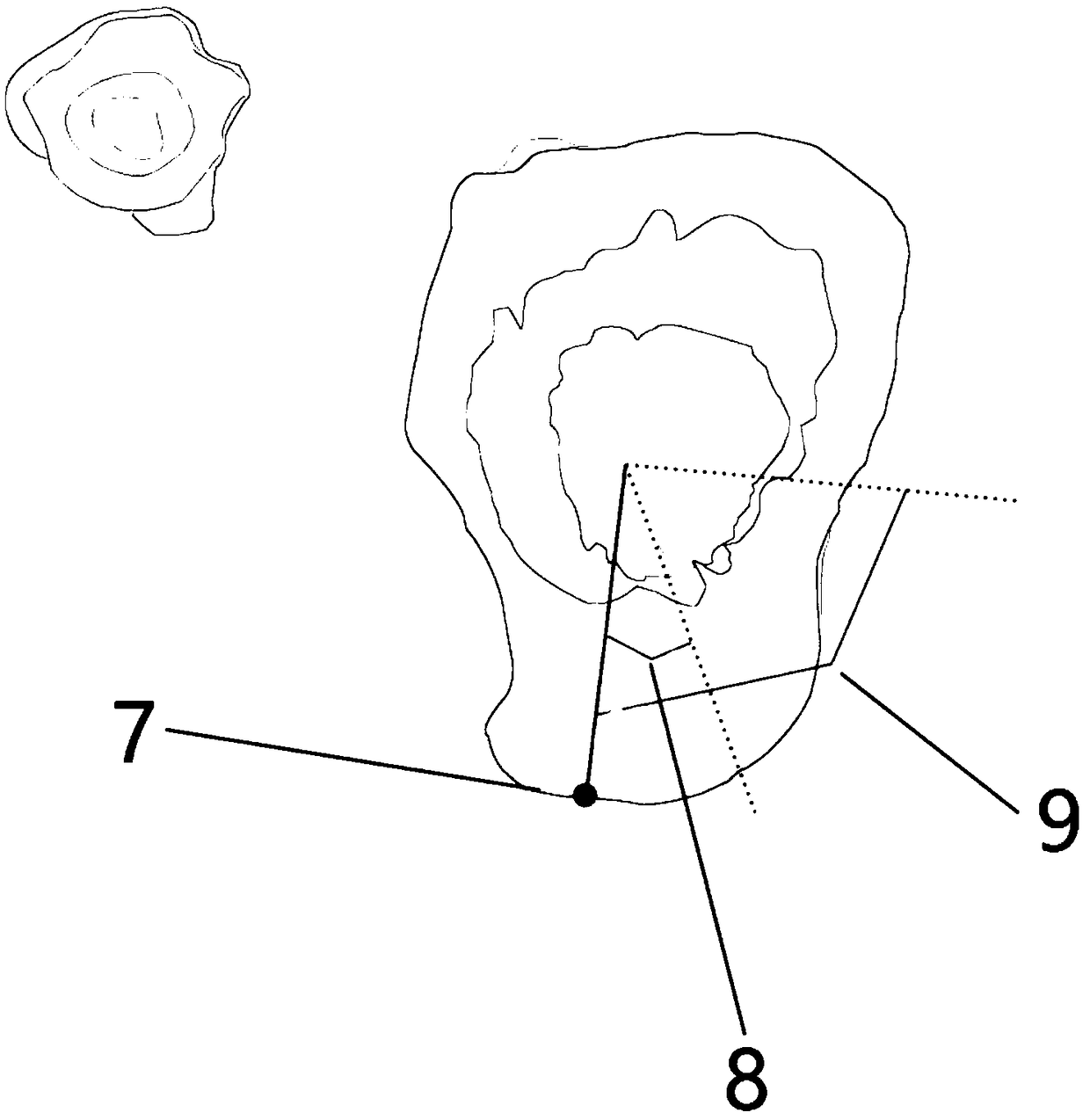

[0095] The three-dimensional model of the tibia was used as the basis of the coordinate system, and the tibial plateau was used as the axial reference. The point cloud of the tibial plateau was selected to fit a plane, and the normal direction of the plane was used as the reference direction to define the upper and lower boundaries of the guide plate. Select the medial and lateral axial plane of the tibial tubercle as the rotation reference, such as figure 2 shown. The center of the tibial tuberosity is 30-40 mm inward as the rotation axis point, the rotation reference axis is located in the medial and lateral medial axis plane of the tibial tubercle, and is perpendicular to the fitting surface of the tibial plateau, the starting point is the rotation axis point, and the end point is the tibial tubercle center. Define the left and right boundaries of the guide plate with the reference axis of rotation, and rotate 30 degrees (the left limit angle) and 95 degrees (the right li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com