Whole tailings paste continuous agitating machine provided with liquid level regulation and control device

A control device and mixer technology, which is applied to mixers, mixer accessories, mixers and other directions with a rotating mixing device, can solve the problems of large liquid level fluctuations, hidden dangers in safety production, and error-prone, to strengthen the mixing and shearing effect. , Avoid overflow accident, strengthen the effect of shearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

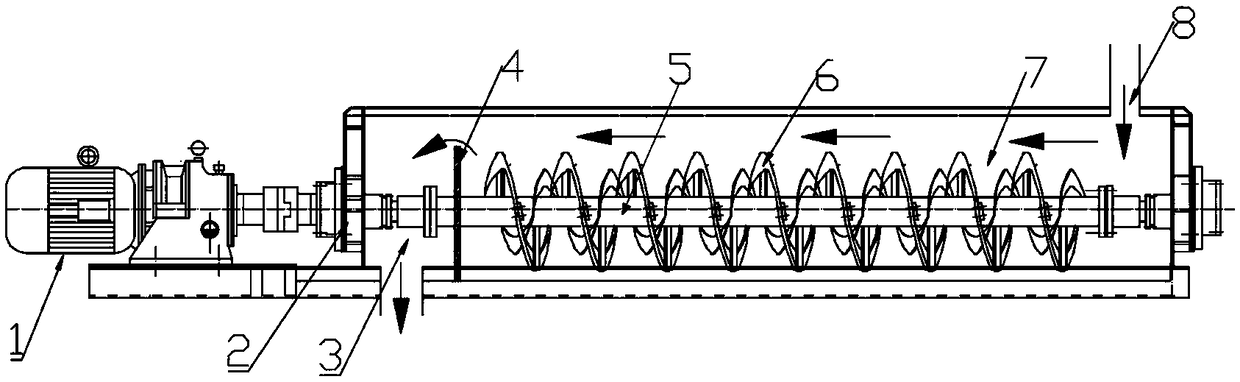

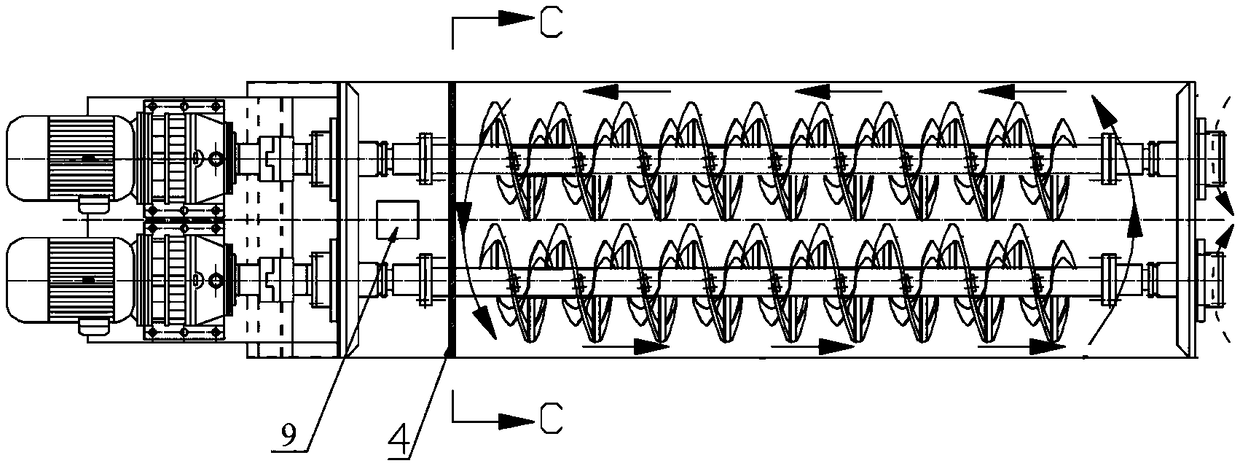

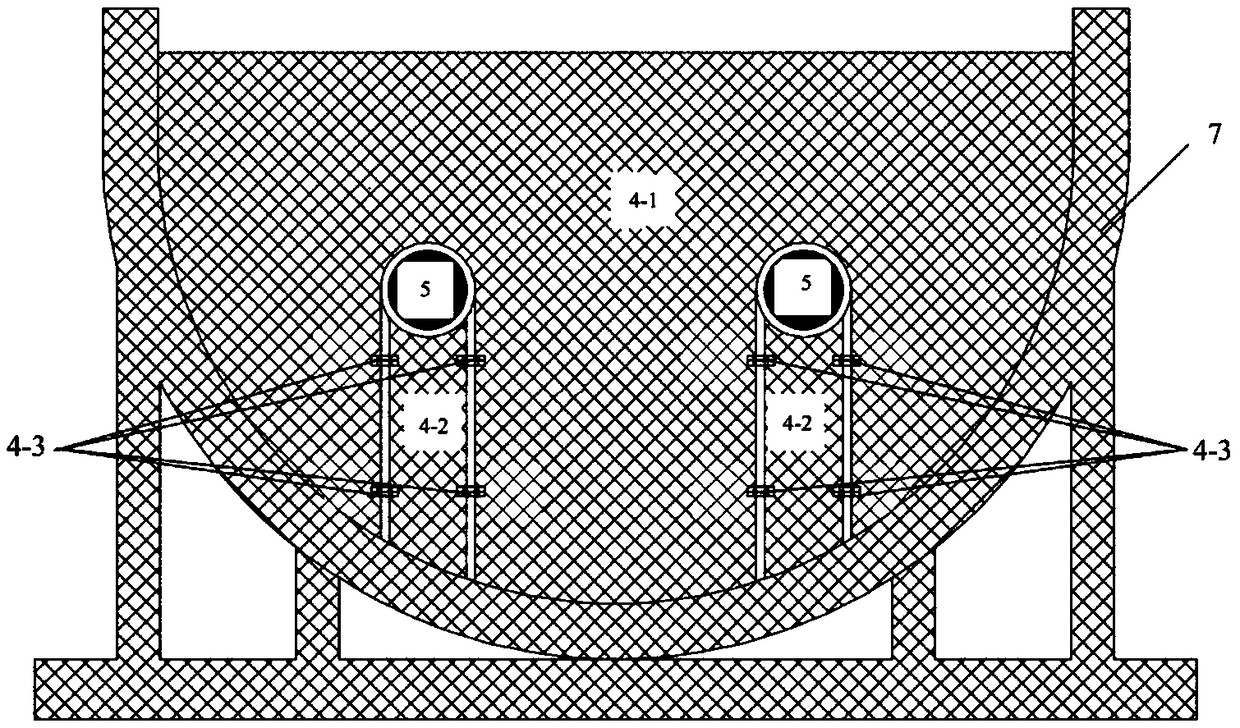

[0053] A mine adopts the filling process of deep cone thickener, double-shaft continuous mixer and plunger pump. The underflow concentration of the whole tailings after thickening is about 75%. The thickened tailings are sent to the mixer together with cement to prepare The mass fraction is about 77% paste, and finally pumped to the downhole stope through the plunger. In the embodiment of the present invention, the structure of the traditional mixer is modified, and the U-shaped feeding structure is modified by adding a liquid level control device, and the reverse operation of the two shafts is realized. After the material enters the mixing tank, the liquid level is raised under the action of the main board in the liquid level control device, and a high liquid level multi-cycle migration mode is formed under the dual-axis drive of the reverse movement. Under the premise of constant production capacity, the stirring time can be extended to About 3 minutes. The distance between...

example 2

[0056] A mine uses full tailings cemented filling technology, and adopts a filling process combining vertical sand bins, double-shaft continuous mixers and gravity conveying. After the tailings are thickened by the vertical sand silo, the underflow concentration is about 65%. The thickened tailings and cement are sent to the mixer to mix into a filling slurry with a mass fraction of about 68%, and finally flow to the underground stope by gravity. The mixer adopts the device and method provided by the present invention, and is equipped with a liquid level control device, a U-shaped feeding structure and a dual-axis reverse operation model. The distance between the mixer bearing, the feeding port and the overflow plate is 15cm, the height of the liquid level control device is 2cm higher than the top of the mixer blade, and the mixing blades are spiral and move inversely to each other. After the material enters the mixer, it forms a surrounding flow and multi-circulation movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com