Liquid mixing device and control method

A liquid mixing device and liquid technology, applied in the direction of mixers, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve the problems of unreliable control and low accuracy, so as to reduce operating costs, reduce errors, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

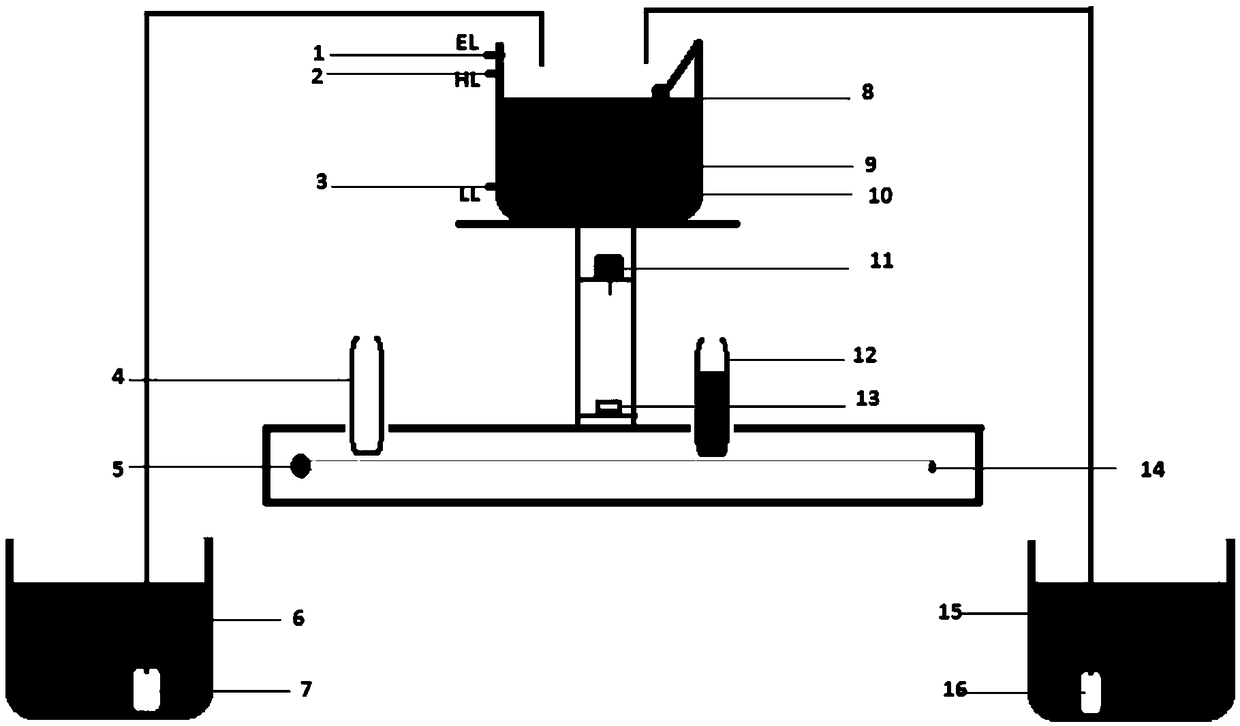

[0022] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0023] Liquid mixing devices are used to mix two liquid mixtures in equal proportions. like figure 1 As shown, the liquid mixing device includes a first liquid storage tank 6 and a second liquid storage tank 15, and liquids to be mixed are stored in the liquid storage tanks. The first liquid storage tank 6 and the second liquid storage tank 15 are connected to the first water pump 7 and the second water pump 16 respectively, and the water is delivered to the mixing tank 10 through the water pumps. The mixing tank 10 is placed on a stand, and the stand is arranged on the side of the belt. The mixing tank 10 is provided with a sensor for sensing the liquid level, and the height of the liquid level is provided with three comparison values, including low liquid level, high liquid level and early warning liquid level. The low liquid level is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com