Printed circuit board type discharge electrode

A technology of discharge electrodes and printed circuit boards, which is applied in the field of discharge electrodes for high voltage discharge, can solve the problems of inconvenient installation, easy bending and breakage of electrodes, and achieve the effects of easy installation and fixation, good vibration resistance and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

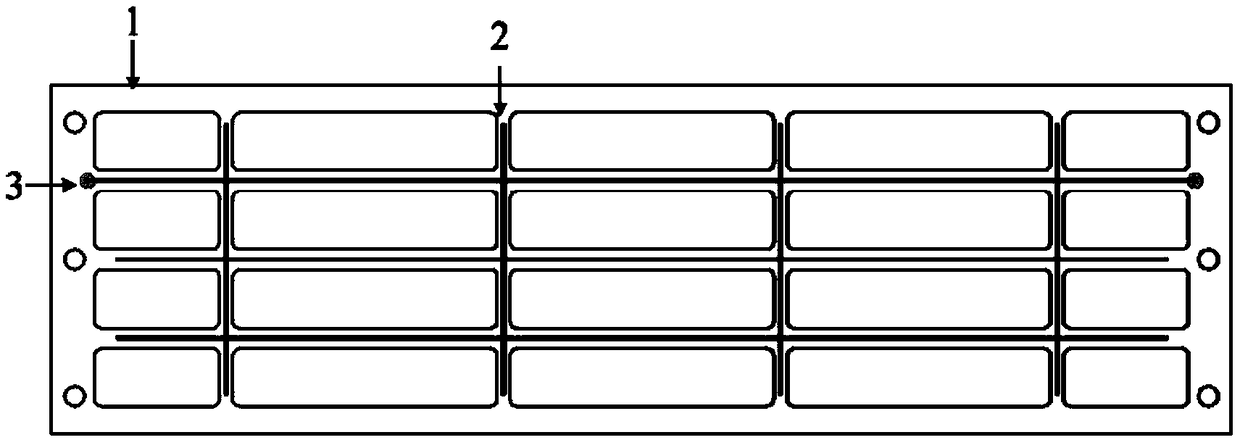

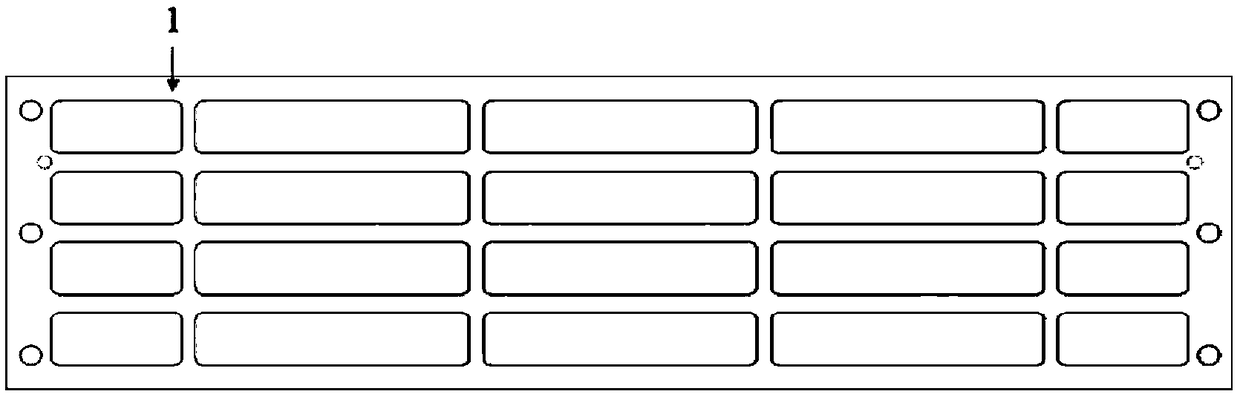

[0026] This embodiment provides a printed wire plate type discharge electrode, see attached figure 1 and 2 , including: substrate 1, wire electrodes 2 and solder joints 3;

[0027] The substrate 1 is a hollow plate made of insulating material to facilitate the passage of airflow, and the thickness of the substrate 1 is not less than 0.5mm; in this embodiment, the substrate 1 is a rectangular plate, and the rectangular plate is processed with rectangular Hollow hole, the rectangular hollow hole separates the rectangular plate into an outer frame and criss-crossing horizontal support beams and longitudinal support beams in the outer frame; the outer frame is used for fixing and installing the substrate 1, and no wire electrodes are printed on it 2. The horizontal support beams and vertical support beams are used to carry the discharge electrodes, on which the wire electrodes 2 are printed, and the distance between adjacent horizontal support beams or adjacent vertical support b...

Embodiment 2

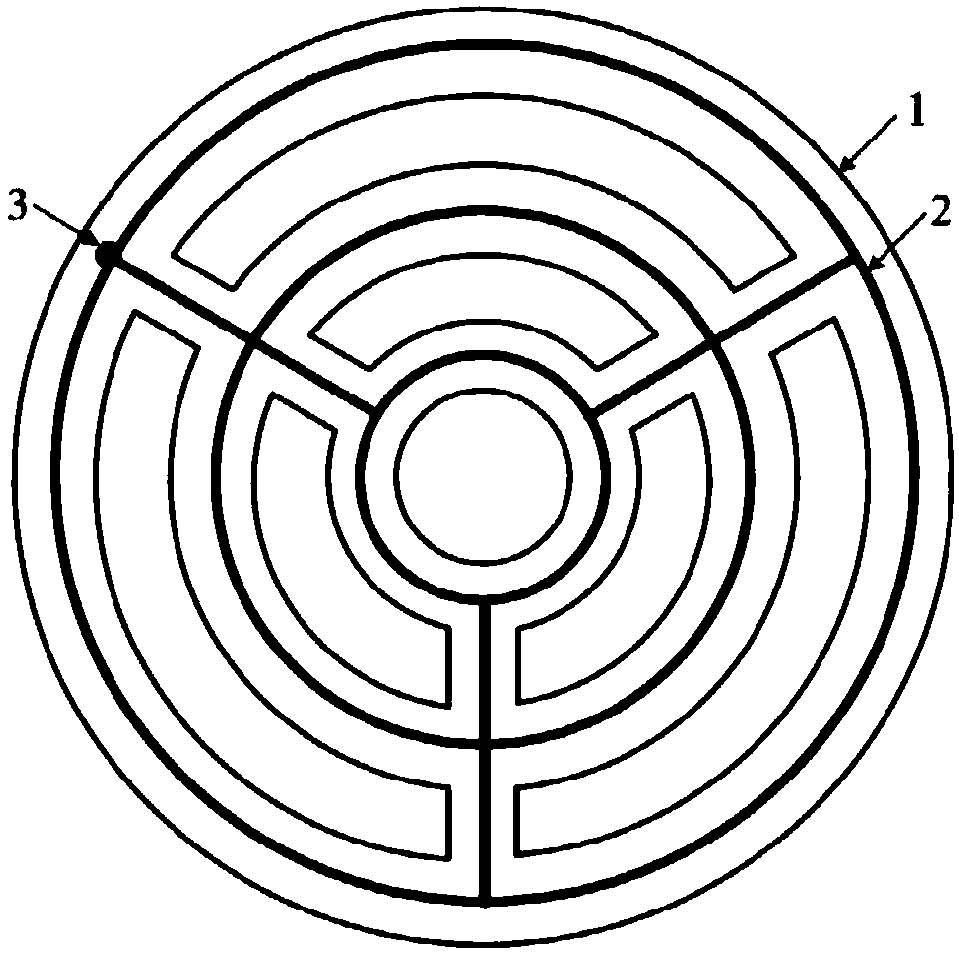

[0033] This embodiment provides a printed wire plate type discharge electrode, see attached image 3 , except that the layout of the substrate 1 shape and the wire electrode 2 is different from that of Embodiment 1, all the others are the same;

[0034] The base plate 1 in this embodiment is a circular plate, and the circular plate is processed with two circles of circularly distributed arc-shaped hollow holes and a central circular hole. The arc-shaped hollow holes and the central circular hole separate the circular plate into Three rings of the shaft and three radial support beams connecting the three rings; the wire electrode 2 is printed on the rings and the radial support beams of the substrate 1 by printing or deposition process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com