Soil cleaning equipment and soil remediation technology

A cleaning equipment and soil remediation technology, applied in the field of soil remediation, can solve the problems of reducing the effect of eluent on soil leaching, and achieve the effects of avoiding repeated treatment, reducing pollution and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

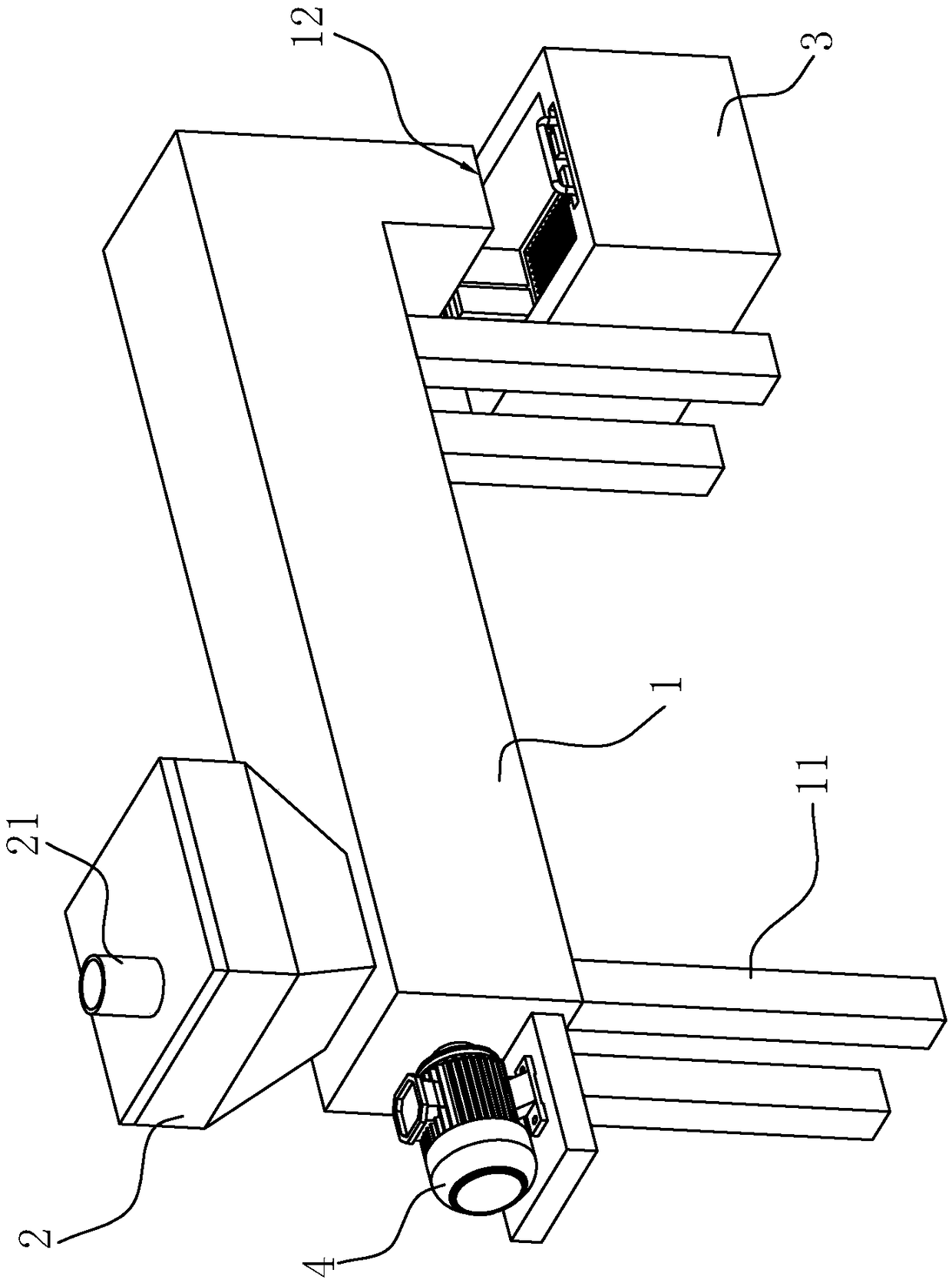

[0047] Embodiment 1: a kind of soil washing equipment, such as figure 1 As shown, it includes a box body 1, four pillars 11 fixed on the bottom of the box body 1 (not limited to four pillars 11), a feed hopper 2 fixed on the top of the box body 1, and a The material receiving box 3 at one end of the hopper 2; the four pillars 11 are scattered at the four corners of the bottom of the box body 1; the inside of the box body 1 is provided with a cleaning channel, and the feeding hopper 2 is connected to the cleaning channel; the box body 1 is far away from the feeding hopper 2 One end is provided with a discharge port 12, and the discharge port 12 faces the material receiving box 3;

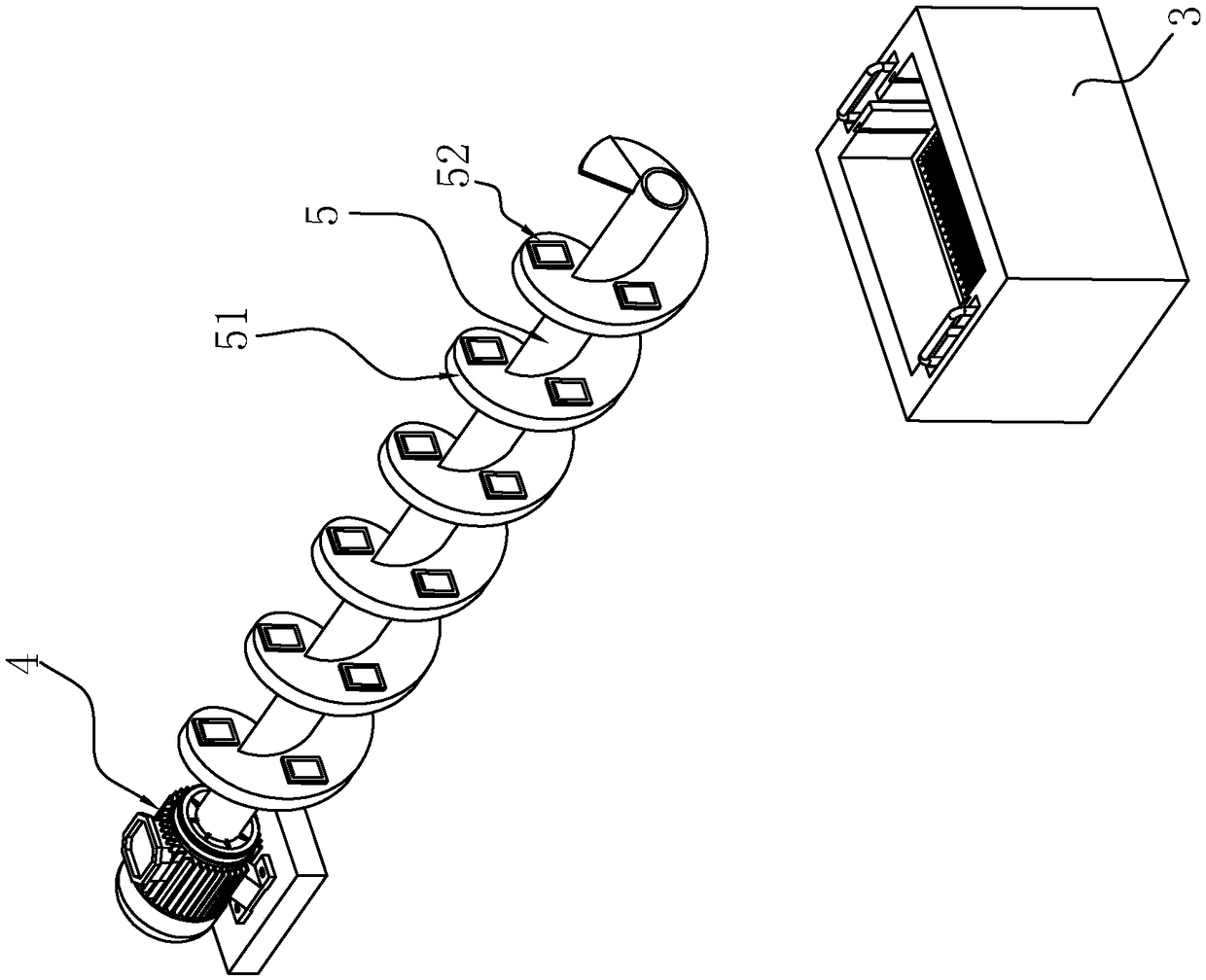

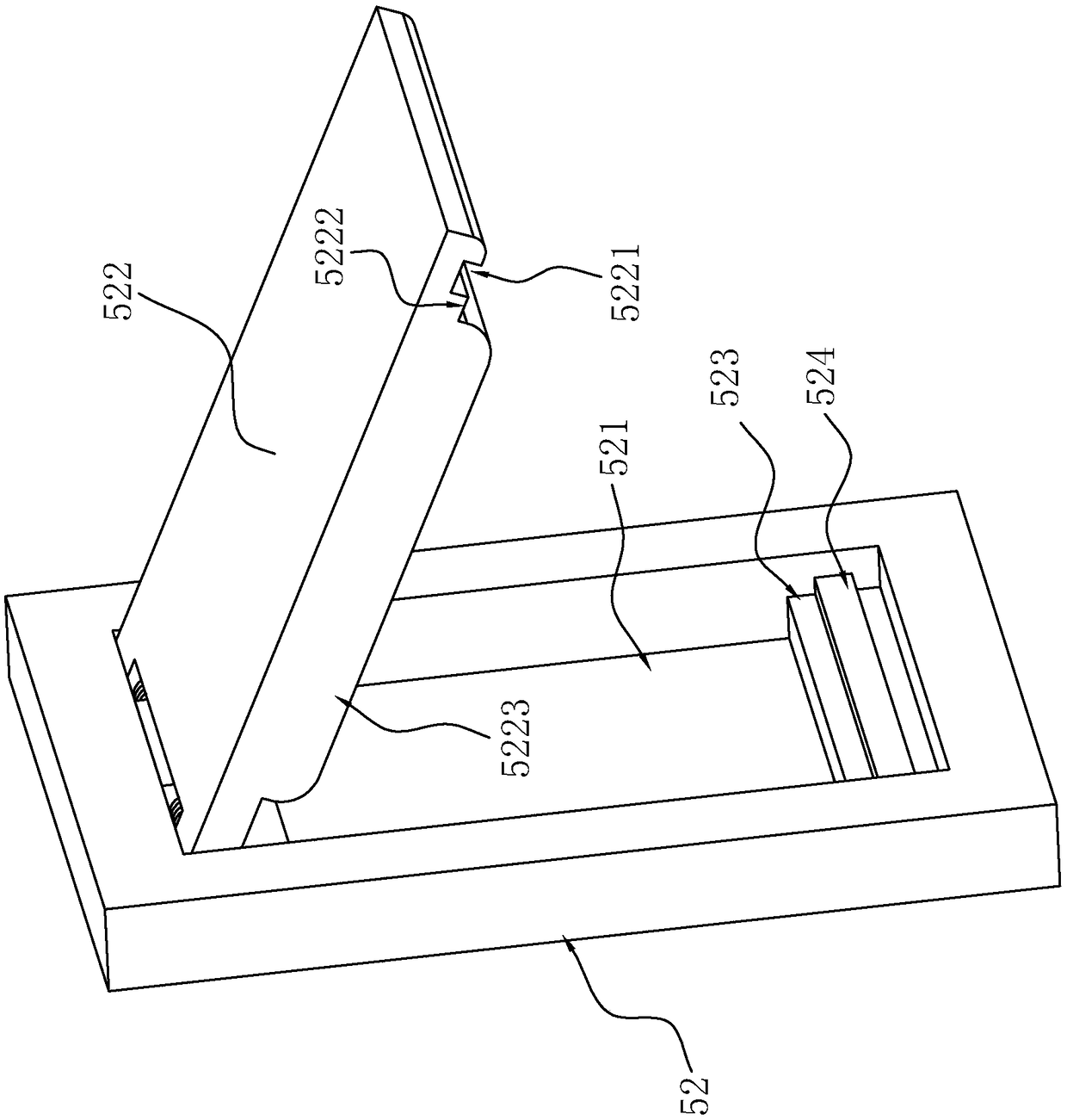

[0048] As pictured and figure 2 As shown, a stirring shaft 5 is rotatably connected to the casing 1, the stirring shaft 5 is a hollow structure and one end of the stirring shaft 5 is connected with a driving motor 4, and the other end extends out of the casing 1; the driving motor 4 is fixedly conn...

Embodiment 2

[0057] Embodiment 2: a kind of soil restoration technique, comprises the following steps:

[0058] Step 1. Sampling at one time: Divide the area of contaminated soil, divide the contaminated area into several small areas, and insert pillars at the corners of the boundaries of each area, and connect adjacent pillars through lines; A small area of it is sampled.

[0059] Step 2. Sieving: put the sampled soil into the sieving machine for sieving, so as to classify the size of the soil particles and filter out the stones mixed in the soil.

[0060] Step 3, chemical rinsing: the sub-sieved soil enters the casing 1 of the soil cleaning equipment through the feeding cylinder 21 and the feeding hopper 2. After the chemical agent is configured in the cleaning tank, start the water pump and put the soil in the cleaning tank. The medicament enters the stirring shaft 5, and sprays out from the water outlet in the spiral stirring paddle 51, so that the cleaning liquid contacts the soi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com