Connecting structure and working method of movable ore groove dust removal system

A mobile dust removal and connection structure technology, applied in the direction of loading/unloading, conveyors, conveyor objects, etc., can solve problems affecting the normal operation of mine tank dust removal, poor lateral compensation effect, and derailment of mobile trolleys, so as to prevent deviation and derailment , reduce the amount of maintenance, reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

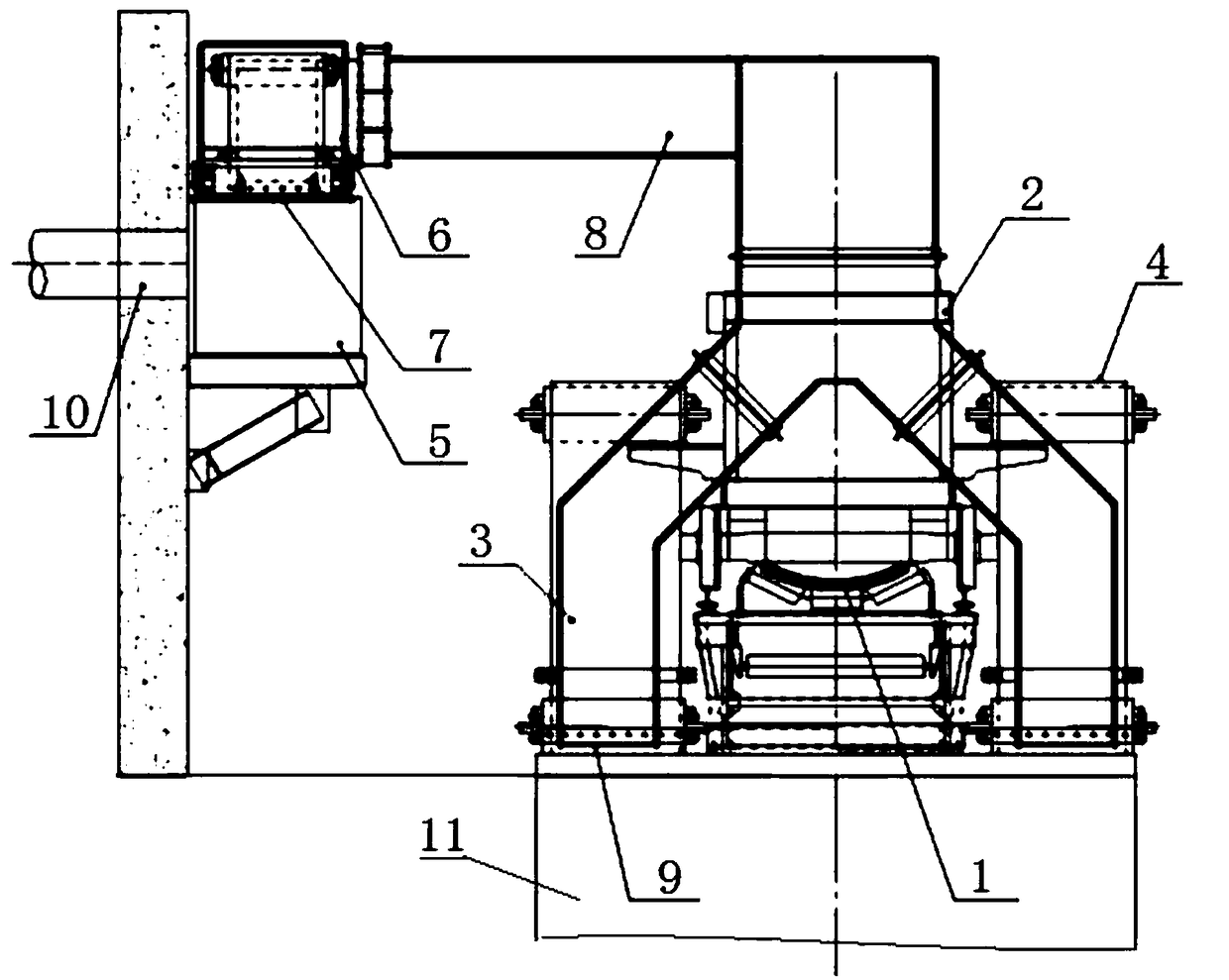

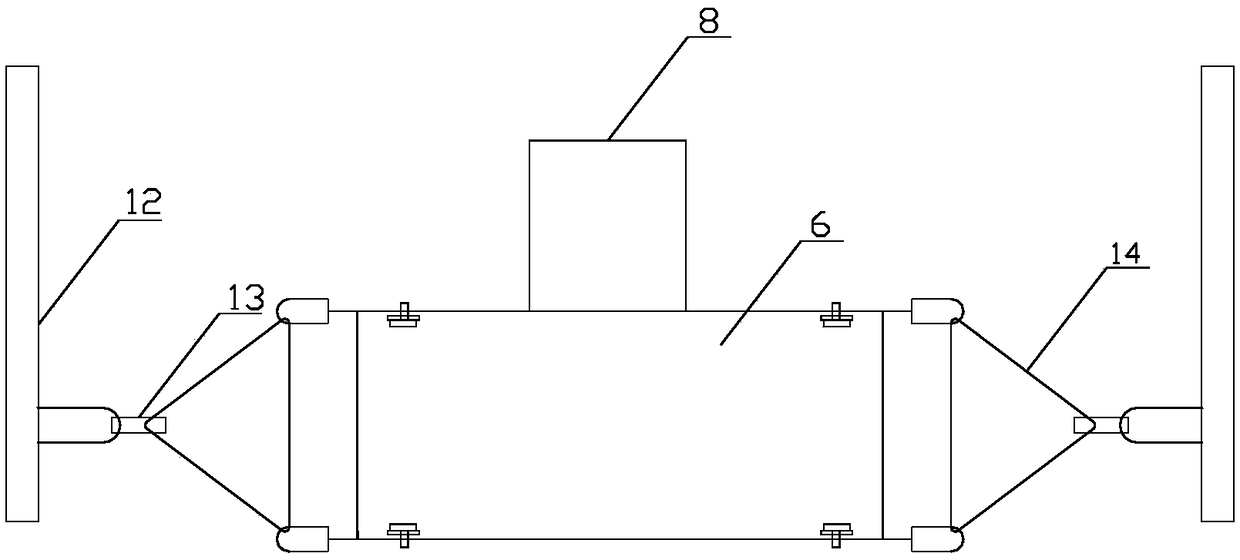

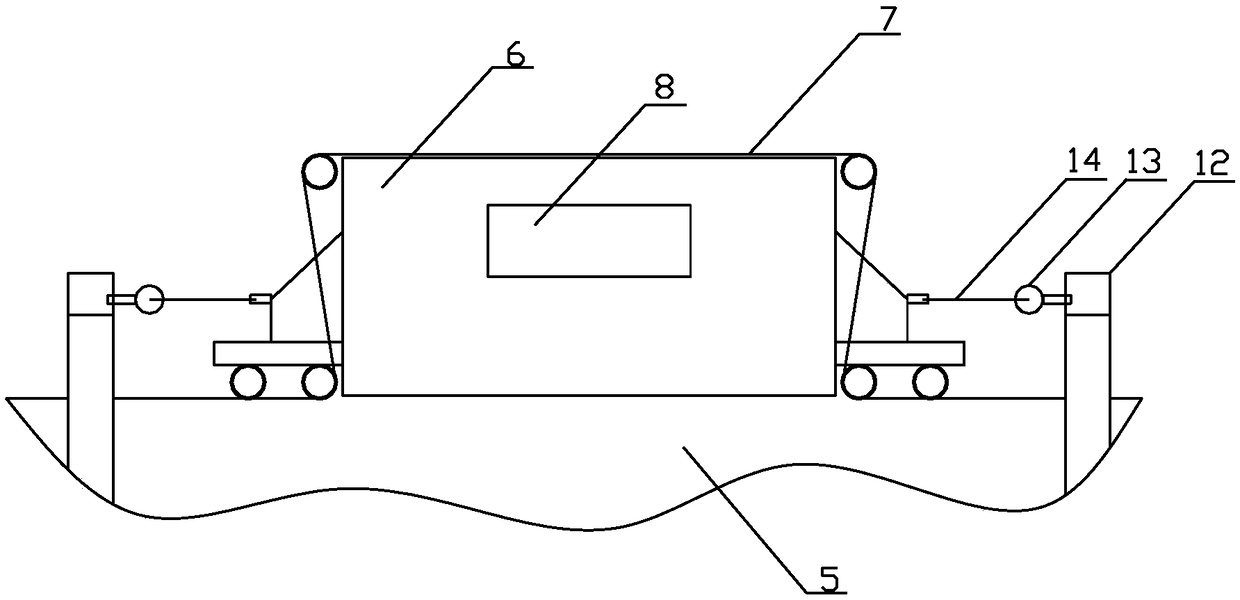

[0028] The connection structure of a mine trough mobile dust removal system described in the present invention, such as figure 1 As shown, the mine trough mobile dust removal system includes a ventilation slot 5, a mobile ventilation trolley 6 and a mobile exhaust pipe 8; the top side of the mine trough 11 is provided with a ventilation trough 5, and the ventilation trough 5 is provided with a mobile ventilation trolley 6, and the mobile ventilation trolley 6 and the ventilation groove 5 are sealed by the ventilation groove sealing belt 7; the head of the discharge belt 1 of the mobile unloading vehicle 2 above the mine trough 11 is provided with a dust cover, and the bottom of the discharge chute 3 on both sides of the mobile discharge vehicle 2 is provided with a The air outlet 9, the mine trough sealing belt 4 is set between the feeding chute 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com