Vial automatic filling machine and filling method thereof

A filling machine and automatic technology, applied in bottle filling, packaging, liquid bottling, etc., can solve problems such as high labor intensity, slow filling speed, and insufficient precision, and achieve the goals of reducing labor, avoiding errors, and improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

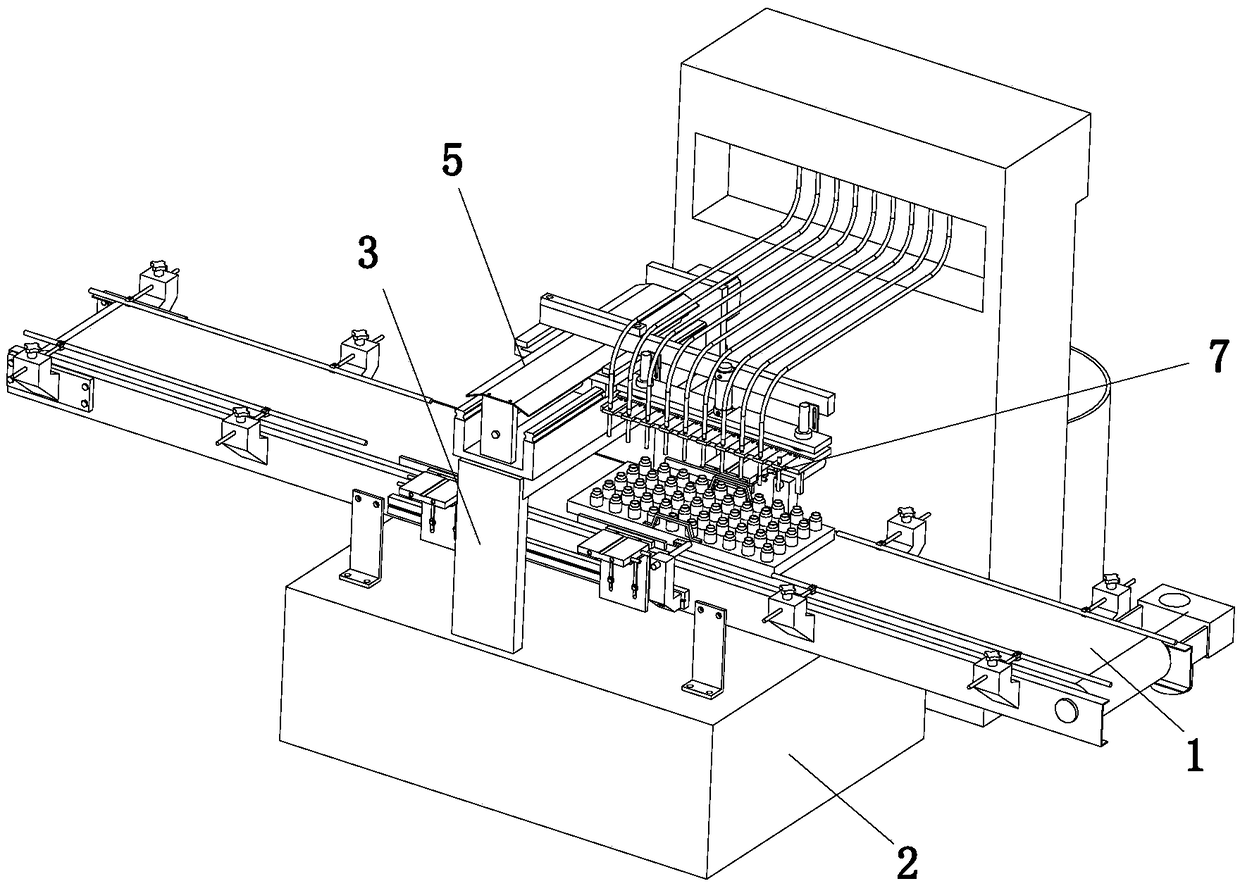

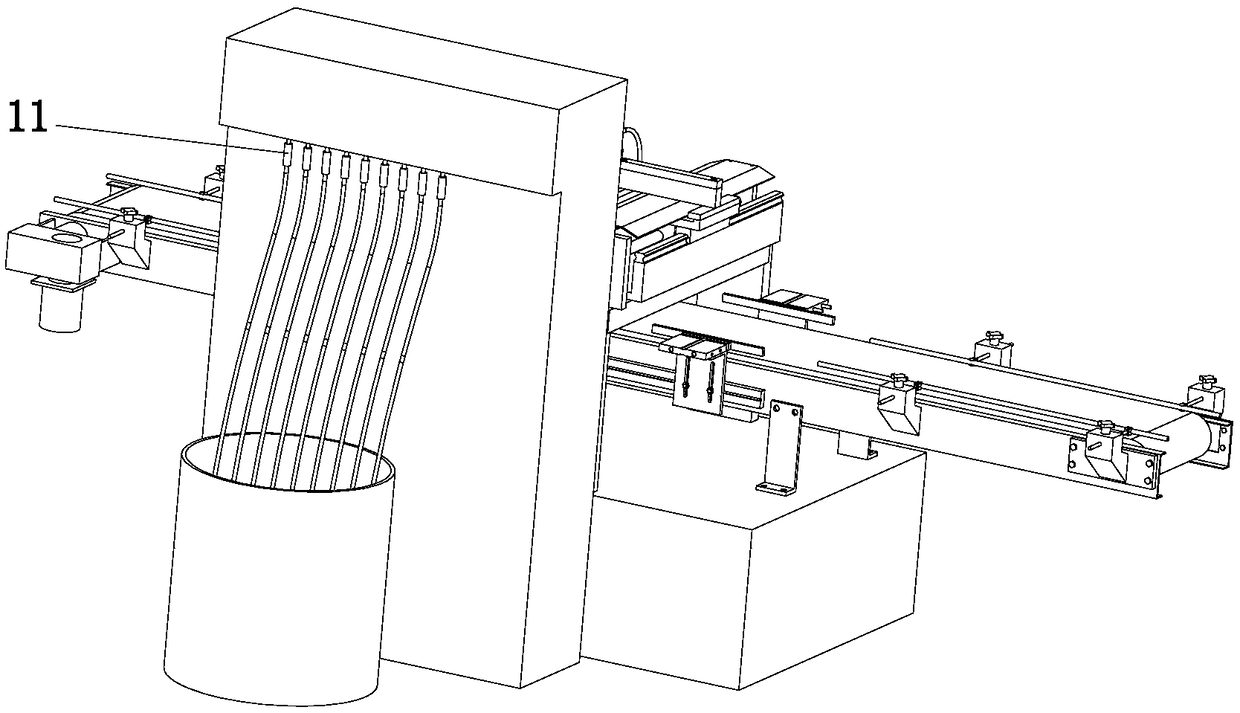

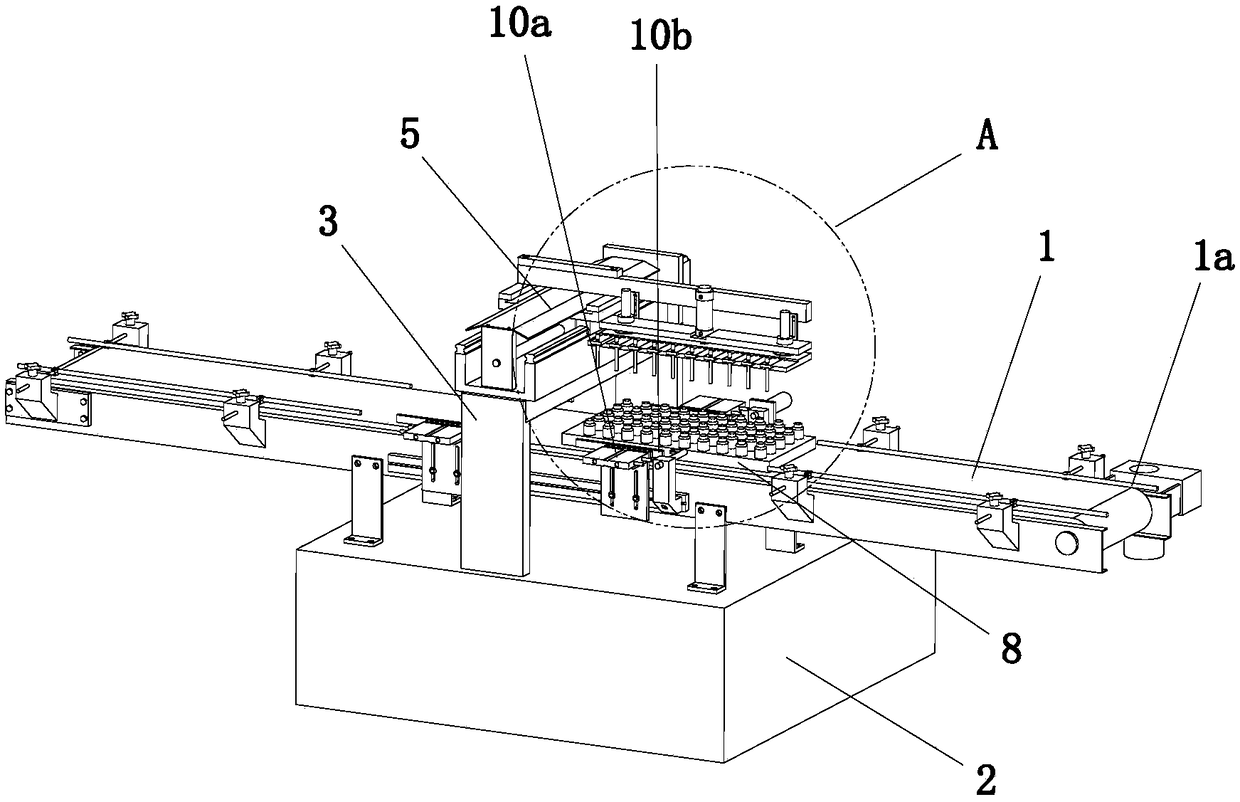

[0035] Such as Figure 1-Figure 7 As shown, a small bottle automatic filling machine includes a conveyor belt 1, a workbench 2, a gantry frame 3, a screw slide table 5, a lifting mechanism, a filling mechanism and a template 8, and the workbench 2 is placed on the conveyor belt 1 Below, the gantry 3 is fixed on the workbench 2, and the gantry 3 is erected on the conveyor belt 1, the screw slide 5 is fixed on the top of the gantry 3, the The lifting mechanism is fixed on the slide table of the screw slide table 5, the filling mechanism is fixed on the moving end of the lifting mechanism, and the filling mechanism can be driven along the vertical direction by the drive of the screw slide table 5. Move horizontally in the direction of the conveying direction of the conveyor belt 1, and the conveyor belt 1 is located within the horizontal movement range of the filling mechanism as the filling area; the template 8 is set corresponding to the bottles used for filling, and there are ...

Embodiment 2

[0045] A method of utilizing the above-mentioned automatic filling equipment to realize non-drip filling, comprising the following steps:

[0046] S1, fill empty bottles on the template 8;

[0047] S2, start the machine, start the filling equipment, and place the template 8 filled with empty bottles on the conveyor belt 1;

[0048] S3. The template 8 is transported to the filling area, and triggers the photoelectric switch 9b arranged on one side of the conveyor belt 1. When the photoelectric switch 9b is touched, the positioning device starts to stop the template 8, and then the clamping device starts to clamp the template 8 left and right. ;

[0049] S4. The lifting device drives all the filling heads 7 down to fill the first batch of empty bottles. After the first batch of filling is completed, the one-way glass valve blocks the filling heads 7; the filling heads 7 move vertically forward to fill The second row, and so on;

[0050] S5. After the filling is completed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com