A method for improving operation reliability of a supercritical water oxidation system and the system

An oxidation system, supercritical water technology, applied in the direction of oxidation treatment of sludge, etc., can solve problems such as salt accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

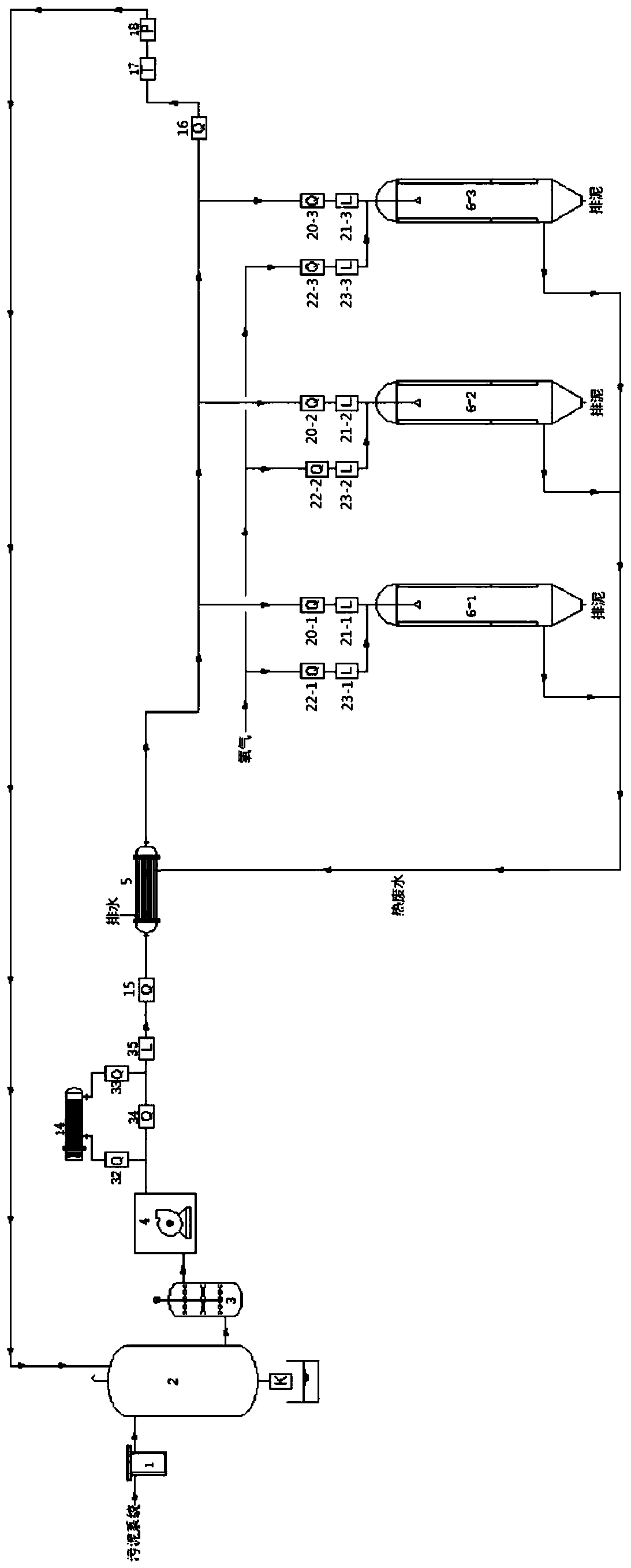

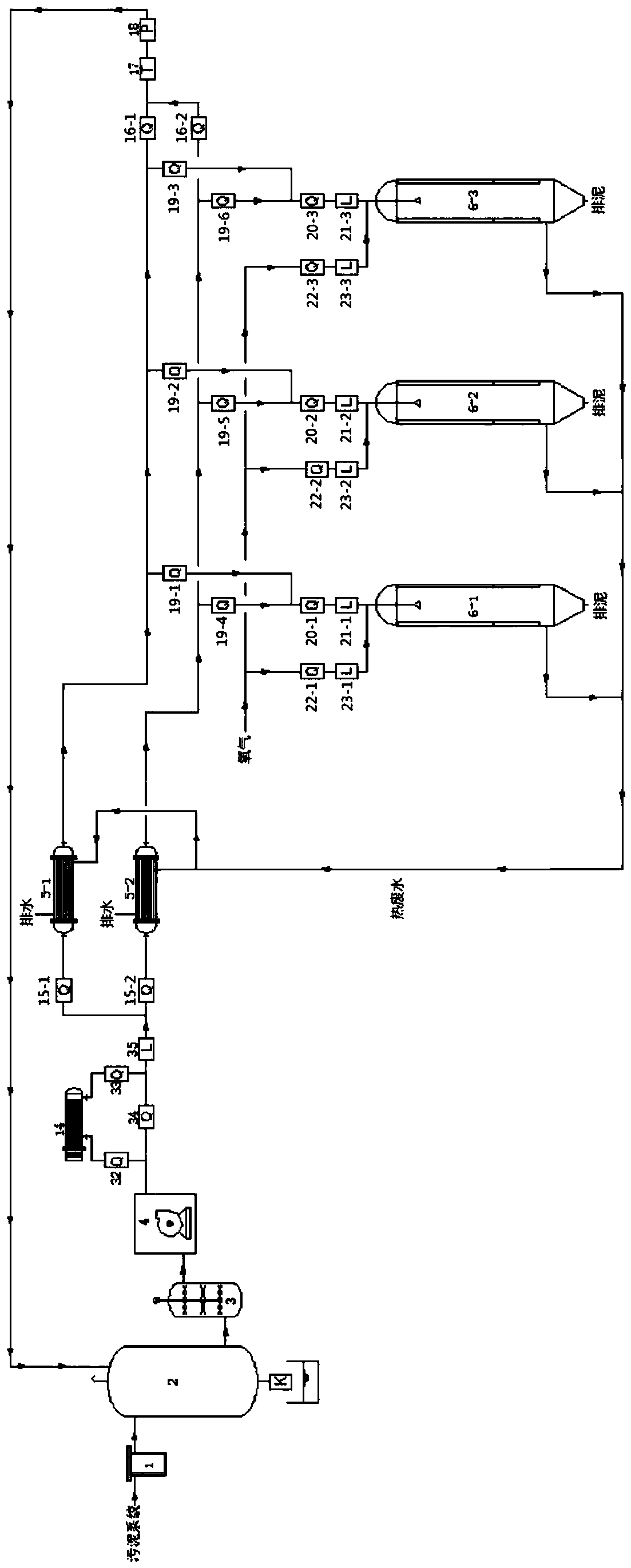

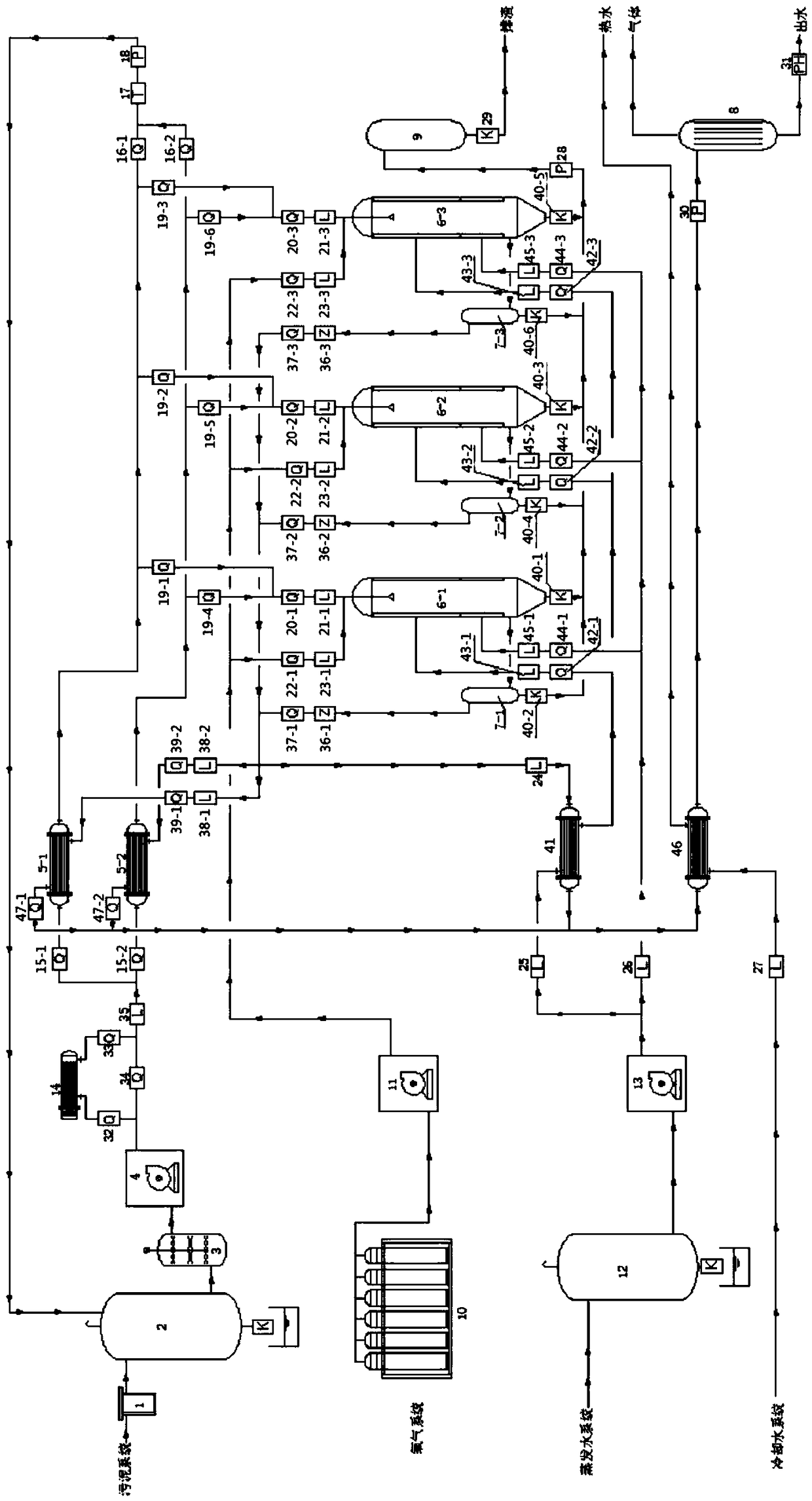

[0076] The content of the present invention will be further described below in conjunction with the examples and accompanying drawings, but it should not be construed as a limitation of the present invention. Without departing from the spirit and essence of the present invention, any modifications or replacements made to the system and method of the present invention belong to the scope of the present invention.

[0077] Unless otherwise specified, the technical means used in the examples are conventional means well known to those skilled in the art. In the examples, the raw materials added are all conventional raw materials unless otherwise specified. The equipment in the system of the present invention is divided into standard equipment and non-standard equipment, wherein the non-standard equipment is mainly a supercritical reactor and various heat exchangers, and the non-standard equipment needs to be designed and manufactured separately according to the actual situation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com