Method for preparing road base material

A technology of road base and boring materials, which is applied in the field of road construction materials, can solve the problems of unfavorable application and development of waste concrete recycled aggregates, increase the production cost of recycled coarse aggregates, and waste recycled aggregate resources, so as to improve long-term road use performance, solve the shortage of sand and gravel, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

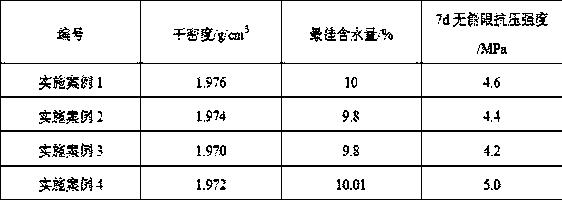

Embodiment 1

[0018] A kind of road base material, each raw material and mass percentage are as follows:

[0019] 40% recycled fine aggregate with a particle size of ~5mm, 29.1% recycled coarse aggregate with a particle size of 5~20mm, 21.8% recycled coarse aggregate with a particle size of 20~30mm, 3% cement, and 6.1% fly ash; is the mass percentage.

[0020] The optimal water consumption of the compound is 10%, and the percentages mentioned are all mass percentages.

[0021] The P.O42.5 cement is used, the fly ash is grade II and above, the fineness modulus of the regenerated fine aggregate is between 3.1-3.7, and the crushing value of the regenerated coarse aggregate is Not more than 35%.

[0022] A preparation method of cement fly ash comprehensive stable recycled aggregate road base material is as follows:

[0023] Mix and stir the recycled aggregates with particle sizes of 0~5mm, 5~20mm, and 20~30mm according to the mass percentages of 40%, 29.1%, and 21.8% respectively, and then a...

Embodiment 2

[0025] A kind of road base material, each raw material and mass percentage are as follows:

[0026] 38.3% recycled fine aggregate with a particle size of ~5mm, 27.8% recycled coarse aggregate with a particle size of 5~20mm, 20.9% recycled coarse aggregate with a particle size of 20~30mm, 2.6% cement, and 10.4% fly ash; is the mass percentage.

[0027] The optimal water consumption of the compound is 9.8%, and the percentages are all mass percentages.

[0028] The P.O42.5 cement is used, the fly ash is grade II and above, the fineness modulus of the regenerated fine aggregate is between 3.1-3.7, and the crushing value of the regenerated coarse aggregate is Not more than 35%.

[0029] A preparation method of cement fly ash comprehensive stable recycled aggregate road base material is as follows:

[0030] Mix and stir the recycled aggregates with particle diameters of 0~5mm, 5~20mm, and 20~30mm according to the mass percentages of 38.3%, 27.8%, and 20.9% respectively, and then...

Embodiment 3

[0032] A kind of road base material, each raw material and mass percentage are as follows:

[0033] 37.4% recycled fine aggregate with a particle size of ~5mm, 27.2% recycled coarse aggregate with a particle size of 5~20mm, 20.4% recycled coarse aggregate with a particle size of 20~30mm, 2.5% cement, and 12.5% fly ash; is the mass percentage.

[0034] The optimal water consumption of the compound is 9.8%, and the percentages are all mass percentages.

[0035] The P.O42.5 cement is used, the fly ash is grade II and above, the fineness modulus of the regenerated fine aggregate is between 3.1-3.7, and the crushing value of the regenerated coarse aggregate is Not more than 35%.

[0036] A preparation method of cement fly ash comprehensive stable recycled aggregate road base material is as follows:

[0037] Mix and stir the recycled aggregates with particle diameters of 0~5mm, 5~20mm, and 20~30mm according to the mass percentages of 37.4%, 27.2%, and 20.4% respectively, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com