Paper film-based cleaning tape and preparation method thereof

A thin film and clean technology, applied in the field of paper tape, can solve the problems of waste of forest resources, environmental pollution, etc., and achieve the effects of energy saving, excellent environmental protection performance, and reduction of raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with the drawings and specific embodiments.

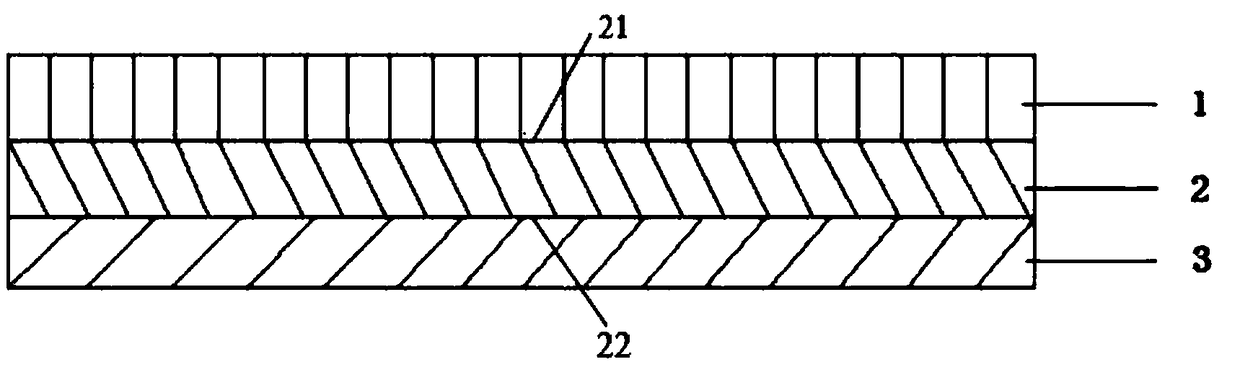

[0022] This embodiment provides a paper film cleaning tape, comprising a release layer 1, a paper substrate layer 2 and an adhesive layer 3 arranged in sequence, the release layer 1 is a UV curing release agent, and the paper substrate Layer 2 is stone paper, and the adhesive layer 3 is UV-curable pressure-sensitive adhesive glue. Compared with textured paper, stone paper is used as the substrate. It has the characteristics of low cost and controllable degradation, which can save a lot of users. Compared with the traditional heat curing type, UV curing type release agent and glue only need UV lamp irradiation to complete the curing. Need to consume a lot of heat energy, and will not cause pollution.

[0023] The paper substrate layer 2 has a f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap