An anode carbon block carbon bowl cleaning unit convenient for subsequent transportation and its use method

A technology of anode carbon block and carbon bowl cleaning tank, which is applied in the field of electrolytic aluminum equipment manufacturing, can solve problems such as unsatisfactory noise and dust control effects, trapezoidal box sealing effects, etc., to achieve a high degree of automation, reduce equipment noise, and improve work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: (no ash outlet 31, no through hole 34)

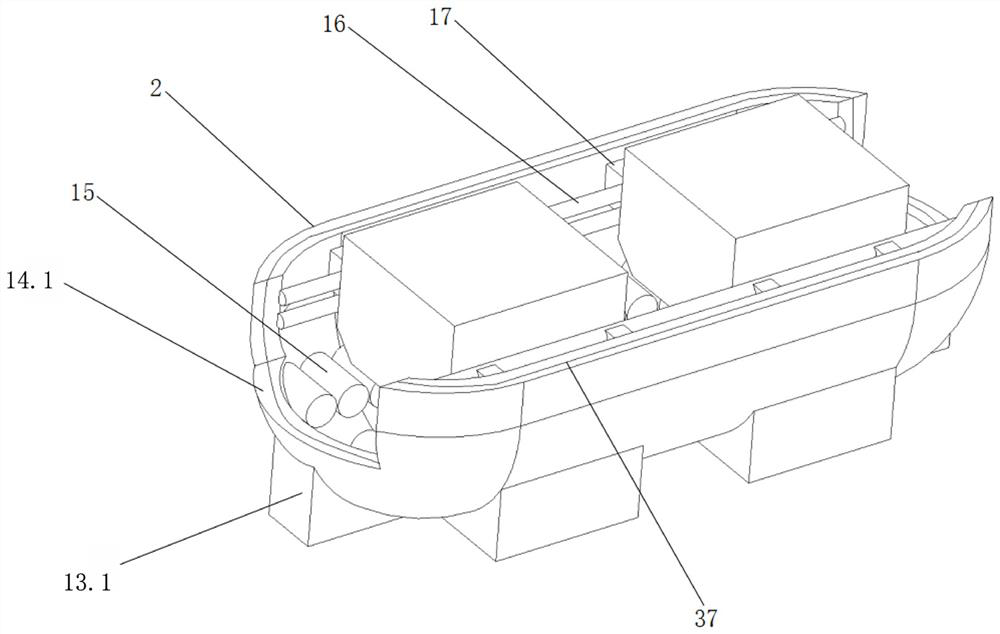

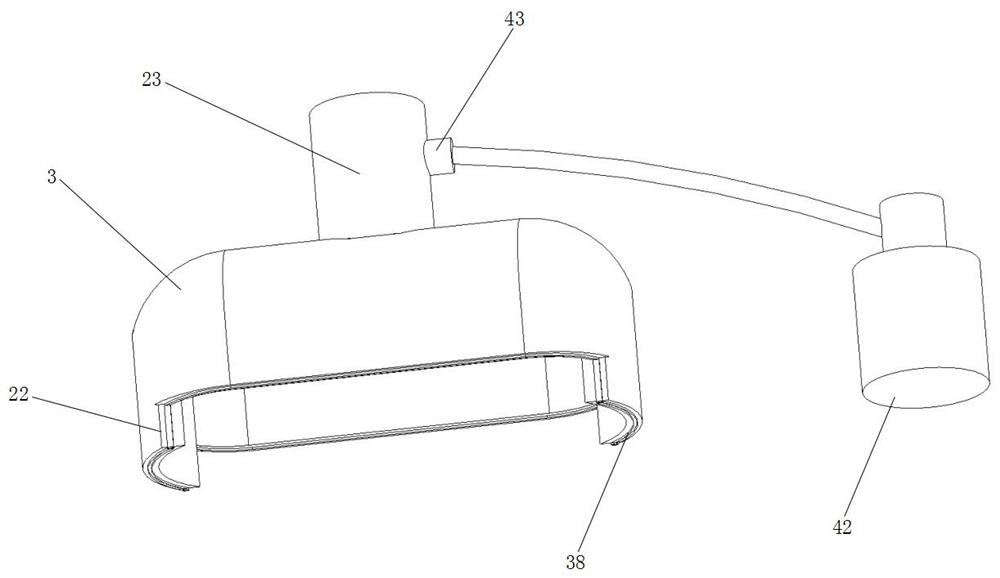

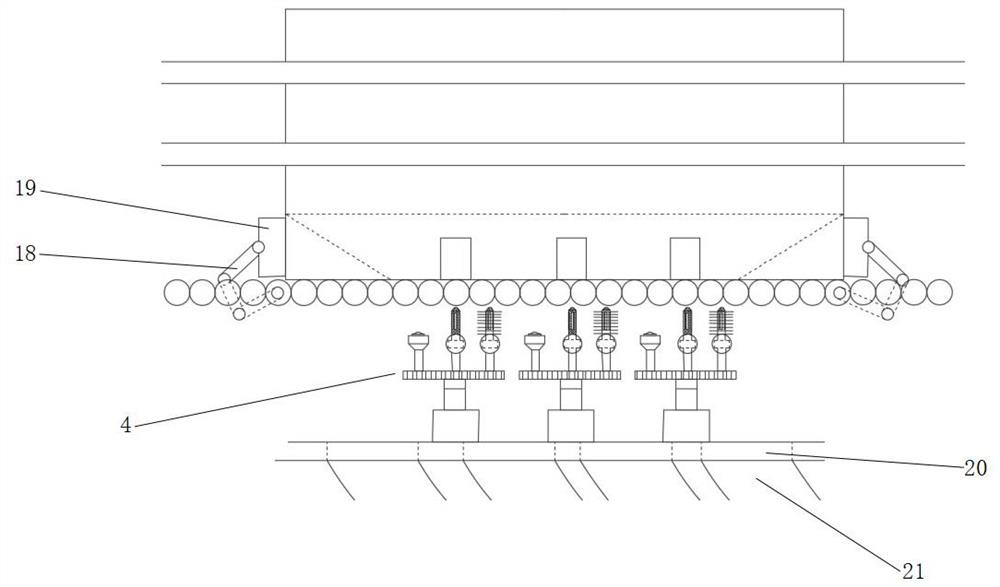

[0041] As shown in the accompanying drawings of the description, an anode carbon block and carbon bowl cleaning unit that is convenient for subsequent transportation includes an anode carbon block 11, and also includes an inlet conveying device 1, a carbon bowl cleaning tank 2, a fully enclosed dust cover 3, and a carbon bowl cleaning Device 4 and control system; the entrance conveyor 1 starts on the ground, and is provided with a lifting conveyor belt 7; the lifting conveyor belt 7 is connected to the carbon bowl cleaning tank 2; the carbon bowl cleaning tank 2 is placed horizontally Arc-shaped trough structure, with openings 14.1 at both ends, and a roller conveying mechanism 15 inside; an upright guardrail 16 is provided on the side inner wall of the carbon bowl cleaning tank 2; the fully enclosed dust cover 3 is arranged on Just above the carbon bowl cleaning tank 2, corresponding to the carbon bowl cleaning tan...

Embodiment 2

[0051] Embodiment 2: (with ash outlet 31, without through hole 34)

[0052] The structure and principle of this embodiment 2 are basically the same as that of embodiment 1, except that the cleaning drill bit 30 and the rotating brush head 32 are provided with an ash outlet 31; part of the carbon bowl filling ash powder passes through the ash outlet 31 and the Vacuum through hole 20. The ash outlet 31 facilitates the discharge of the carbon bowl filler ash powder when cleaning the carbon bowl.

Embodiment 3

[0053] Embodiment 3: (no ash outlet 31, with through hole 34)

[0054] The structure and principle of this embodiment 3 are basically the same as that of embodiment 1, the difference is that the turntable 33 also includes a through hole 34; the through hole 34 runs through the turntable 33; part of the carbon bowl filling ash powder passes through the through hole 34 and absorbs Dust through hole 20. The through hole 34 facilitates the discharge of the carbon bowl filling ash powder when cleaning the carbon bowl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com