Central well completion tubing string for gaslift production and gaslift construction method

A well completion string and gas lift technology, which is applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of wellbore fluid accumulation, short validity period, and high construction risk, so as to improve the efficiency of gas lift and benefit The effect of production management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

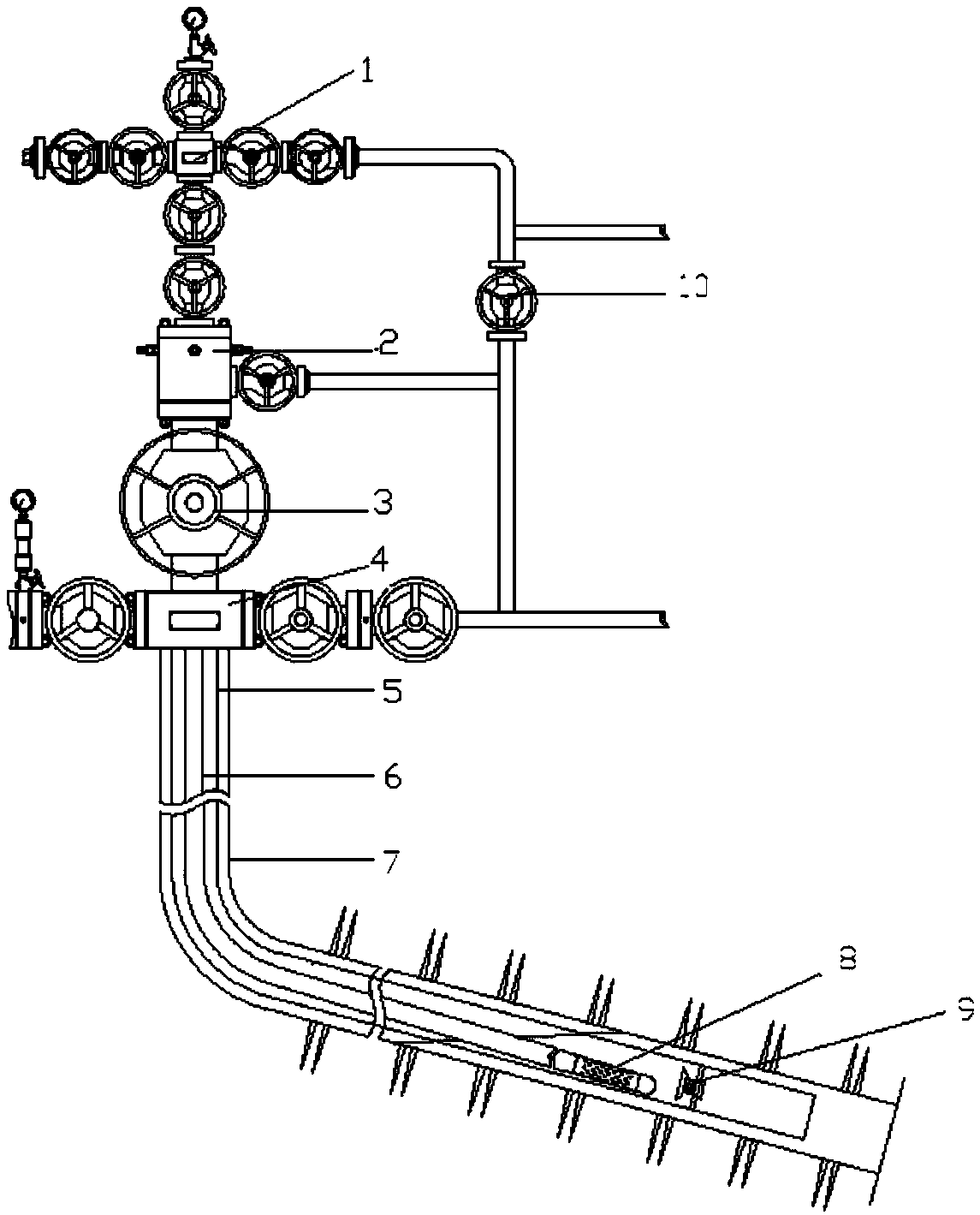

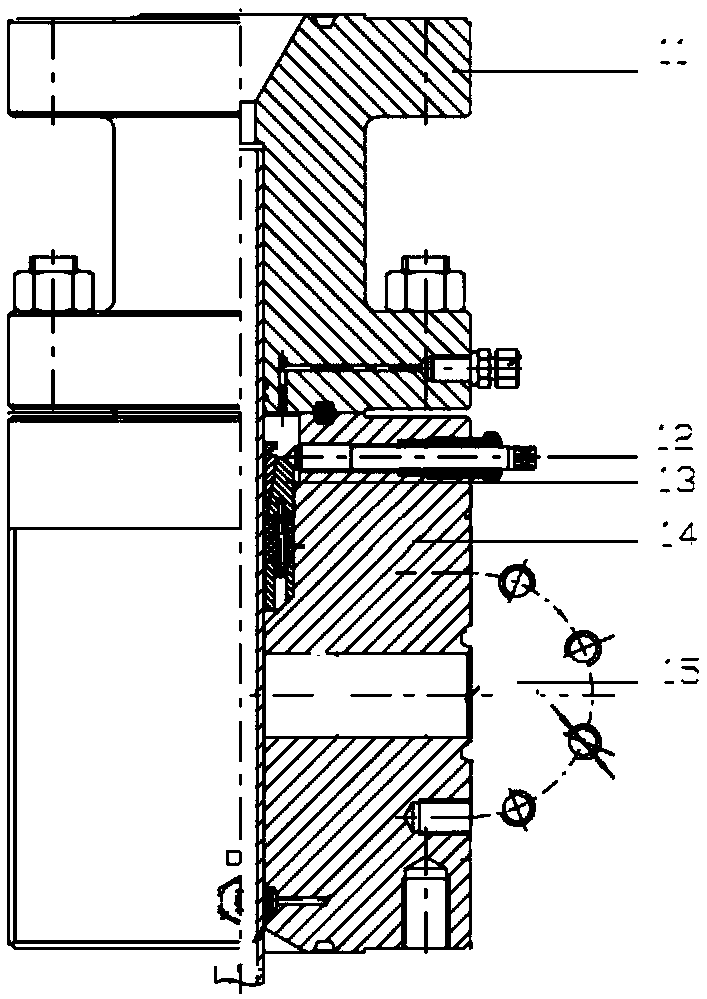

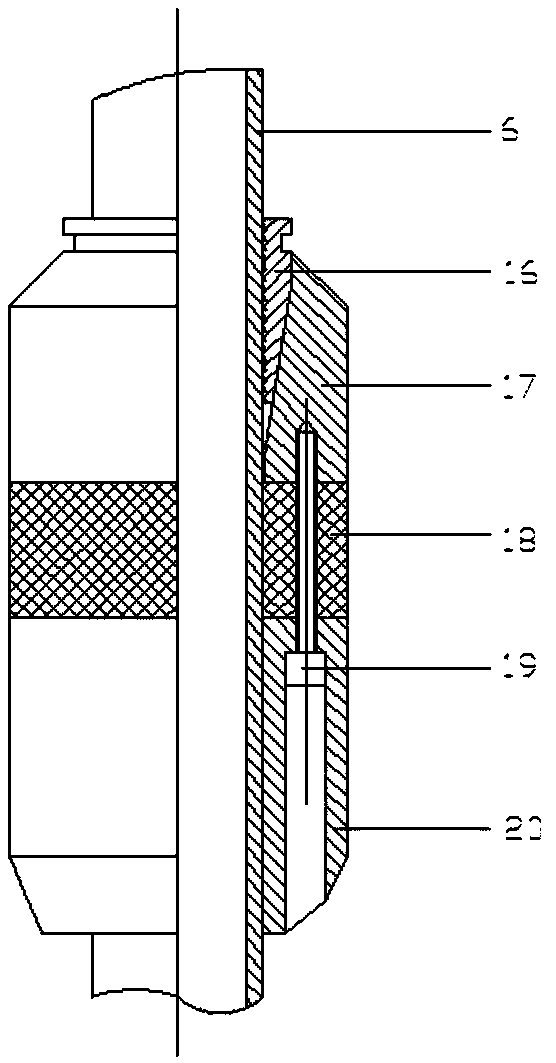

[0041] Such as figure 1As shown, this embodiment provides a central tube completion production string, which includes an external hanger 2, a completion string 5 for snubbing operations, a coiled tubing 6, a plug and a plugging rod, and the coiled tubing 6 The upper end is sealed with the external hanger 2 and is suspended on the external hanger. The external hanger is installed on the upper part of the No. 1 gate valve 3 at the wellhead, and the No. 1 valve 3 at the wellhead is installed above the oil pipe head 4 at the wellhead. The operation completion string 5 is suspended in the tubing head through the hanger. The coiled tubing 6 is suspended 2 by an external hanger and installed in the completion string 5 for hot work. The bottom of the coiled tubing 6 is connected to a plug 8. When the string is lowered, the plug plugs the coiled tubing. The string realizes complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com