Gas engine electrically-controlled gas injection valve testing device and testing method thereof

A technology of gas injection valve and gas engine, applied in the direction of measuring device, testing of mechanical parts, testing of fluid tightness, etc., can solve compressibility, pressure fluctuation, large injection frequency, flow difference, single injection volume and injection problems with rules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

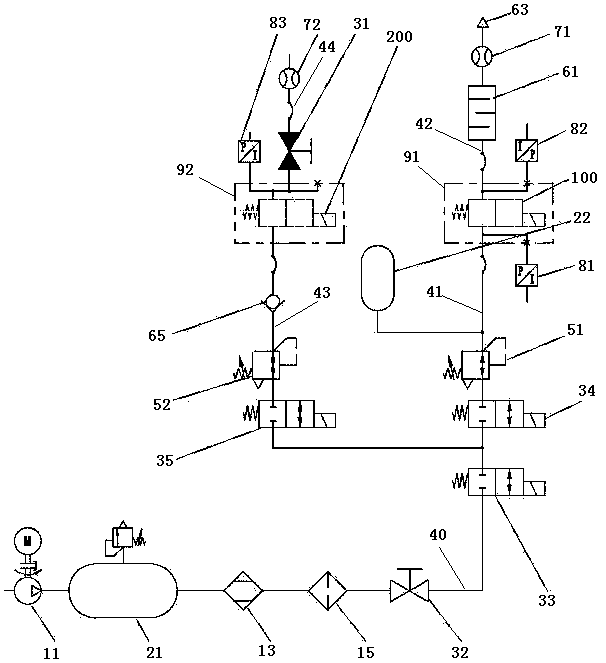

[0024] figure 1 A schematic structural view of an embodiment of the gas engine electronically controlled gas injection valve testing device of the present invention is shown. see figure 1 According to an embodiment of the present invention, the gas engine electronically controlled gas injection valve testing device includes an air supply mechanism, a flow testing mechanism and a leakage testing mechanism.

[0025] The air supply system is used to provide dry and pure air with a certain pressure to the flow test mechanism and leakage test mechanism. The air supply mechanism includes an air source 11 , a first air storage tank 21 , a dryer 13 , a filter 15 , a second stop valve 32 , a third stop valve 33 and a main pipeline 40 . The inlet of the main pipe 40 communicates with the outlet of the air source 11, and the outlet of the main pipe 40 constitutes the outlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com