Acceleration condition rationality evaluation method for material creep life test

A technology of creep life and evaluation method, which is applied in the direction of analyzing materials, using stable tension/pressure to test the strength of materials, measuring devices, etc., which can solve the lack of theoretical basis, the inability to meet the requirements of creep evaluation, and the test without temperature setting Issues such as the impact of the rationality of the scheme, to achieve the effect of flexible verification and meeting the evaluation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

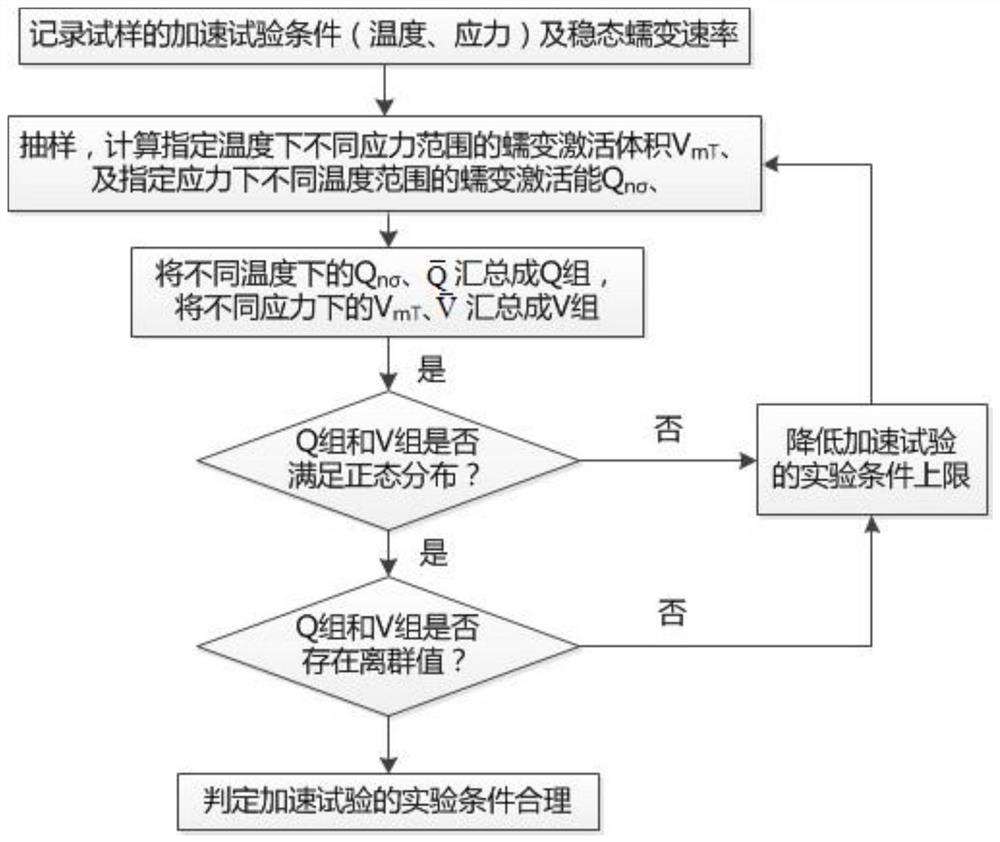

[0042] An evaluation method for accelerated conditions of material creep life test, such as figure 1 shown, including the following steps:

[0043] Step 1: Carry out a creep experiment on the sample according to the standard method. After the experiment is completed, record the experimental conditions and steady-state creep rate of the sample. The experimental conditions include temperature conditions and stress conditions; the temperature conditions include at least three Different temperatures, the stress conditions in step 1 include at least four different stresses;

[0044] Step 2: Select the creep data under the same temperature conditions, divide the creep data subgroups according to the order of the experimental stress from small to large according to the set minimum stress levels, and gradually increase the number of experimental stresses in each creep data subgroup. Stress level, obtain a creep data set for stress evaluation at a predetermined temperature, substitute...

Embodiment 2

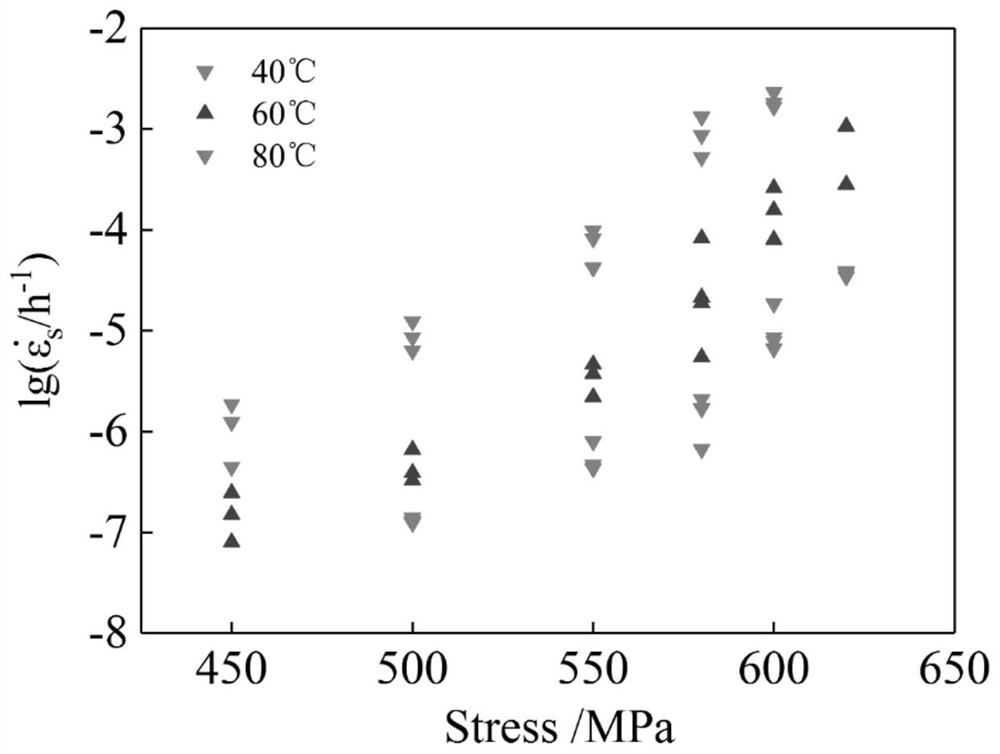

[0058] According to the method in Example 1, this example selects a 7-series high-strength aluminum alloy pre-forged billet (T6 state) as the research object, and the sampling direction of the creep sample is the inner radial direction of the billet (perpendicular to the forging direction of the pre-forged billet). The sample size refers to GB / T2039-1997 "Metal Tensile Creep and Durability Test Method". There are 3 experimental temperature levels (temperature conditions), 40°C, 60°C, and 80°C, and 6 experimental stress levels (stress conditions), 450MPa, 500MPa, 550MPa, 580MPa, 600MPa, and 620MPa.

[0059] Step 1. After the creep life acceleration test is completed, record the experimental conditions (temperature, stress) and steady-state creep rate of the sample. The data distribution is as follows: figure 2 As shown, under each temperature and stress condition, do three sets of parallel tests;

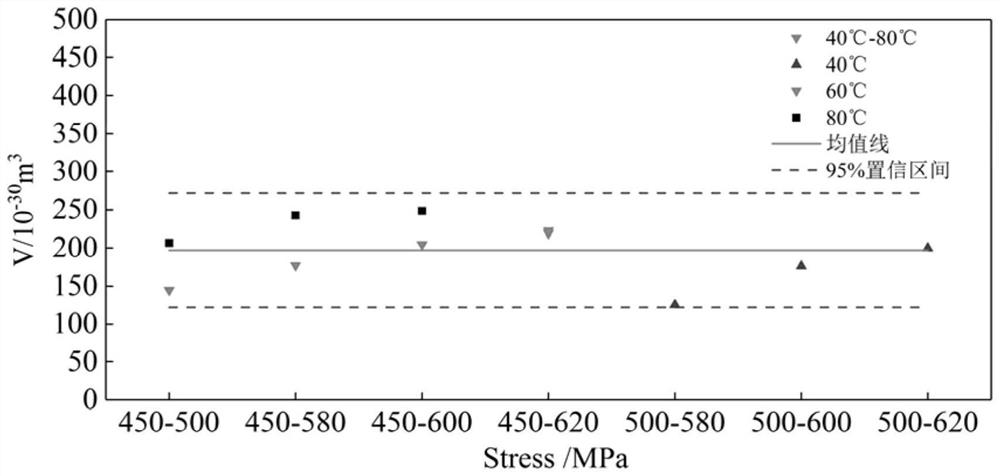

[0060] Step 2, set the minimum number of stress levels to 3, select the creep ...

Embodiment 3

[0069] According to the method of Example 1, this example selects 316H stainless steel plate as the research object, and the sampling direction of the creep sample is the in-plane rolling direction. The sample size refers to GB / T 2039-1997 "Metal Tensile Creep and Endurance Test Method". There are three experimental temperature levels (temperature conditions), namely 500°C, 550°C, and 600°C, and five experimental stress levels (stress conditions), which are 200MPa, 250MPa, 300MPa, 350MPa, and 400MPa.

[0070] Step 1. After the creep life acceleration test is completed, record the experimental conditions (temperature, stress) and steady-state creep rate of the sample. The data distribution is as follows: Figure 5 As shown, under each temperature and stress condition, do three sets of parallel tests;

[0071] Step 2, the minimum number of stress levels is set to 2, and the creep data under the temperature conditions of 500°C, 550°C, and 600°C are respectively selected, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com