Test system and method for testing type-I fracture toughness of deep rock mass

A fracture toughness and test system technology, applied in the field of rock fracture mechanics research, can solve problems such as single experimental purpose, specimen preparation, and complex experimental scheme.

Inactive Publication Date: 2018-12-14

NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

View PDF3 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to provide a test system and test method for testing the I-type fracture toughness of deep rock mass, so as to solve the problem that

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Login to View More

Abstract

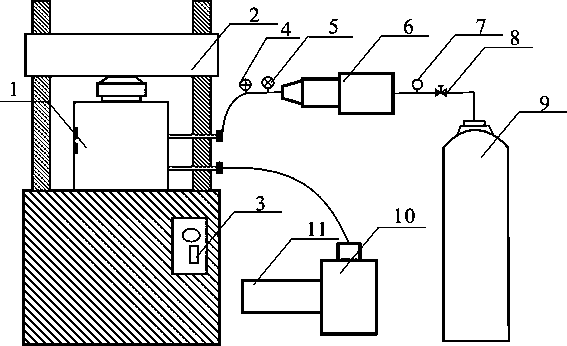

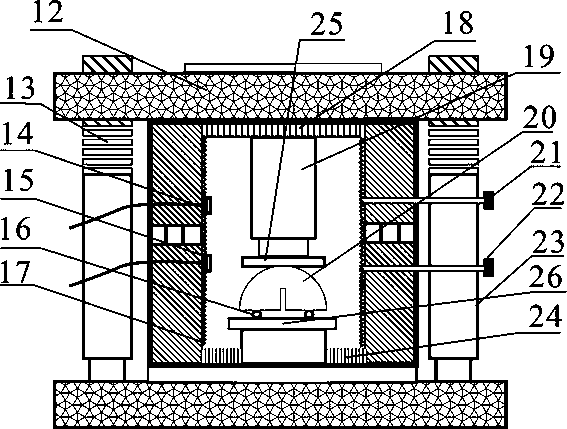

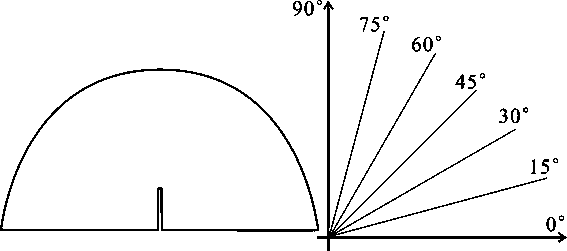

The invention discloses a test system and a test method for testing type-I fracture toughness of a deep rock mass. The test system comprises a semicircular disc rock specimen with an intermediate slit, a loading system for applying an axial pressure to the semicircular disc rock specimen, a vacuum pressure chamber for applying a high-temperature confining pressure to the semicircular disc rock specimen, a vacuum pump for exhausting gas from the vacuum pressure chamber, and an inert gas system for injecting inert gas into the vacuum pressure chamber, wherein the semicircular disc rock specimenwith the intermediate slit is placed in the vacuum pressure chamber; the loading system for applying the axial pressure stretches into the vacuum pressure chamber and acts on the semicircular disc rock specimen with the intermediate slit; two supporting pads are arranged below the semicircular disc rock specimen with the intermediate slit; the two supporting pads are arranged on the two sides of the slit of the semicircular disc rock specimen with the intermediate slit respectively; the vacuum pressure chamber is connected with the inert gas system; a heating device is arranged inside the vacuum pressure chamber. Compared with the prior art, the test system and the test method provided by the invention have the advantages as follows: a real reservoir environment can be simulated, the fracture toughness of the rock can be accurately determinated, and a support is provided for development of deep energy engineering.

Description

technical field [0001] The invention relates to the field of rock fracture mechanics research, in particular to a test system for testing the I-type fracture toughness value of deep rock mass under high temperature and high pressure environment. Background technique [0002] Fracture toughness is an important parameter to evaluate rock mechanical properties (including rock fracture initiation, propagation and fracture mechanism, etc.). Therefore, it is very important to obtain accurate rock fracture toughness values and to design and invent scientific testing and measurement methods. [0003] At this stage, scientists at home and abroad have proposed several testing methods for rock fracture toughness, which have greatly promoted the development of rock fracture mechanics. Franklin (1988) proposed for the first time two methods of testing mode I fracture toughness using V-slit bending specimens (CB) and short rod specimens (SR), and recommended them as the standard of the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/18G01N1/08G01N1/28

Inventor 王洪建袁广祥于怀昌董金玉李垒成王硕楠宋丽娟郭彪王小东

Owner NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com