Battery electric vehicle drive motor rack automatic calibration method and device

A pure electric vehicle and drive motor technology, applied in the field of pure electric vehicle testing, can solve problems such as high work intensity, poor calibration accuracy, and high technical requirements, and achieve the effects of improving work efficiency, increasing the number of sampling points, and improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

[0021] The automatic calibration method of the pure electric vehicle driving motor bench of the present invention comprises the following steps:

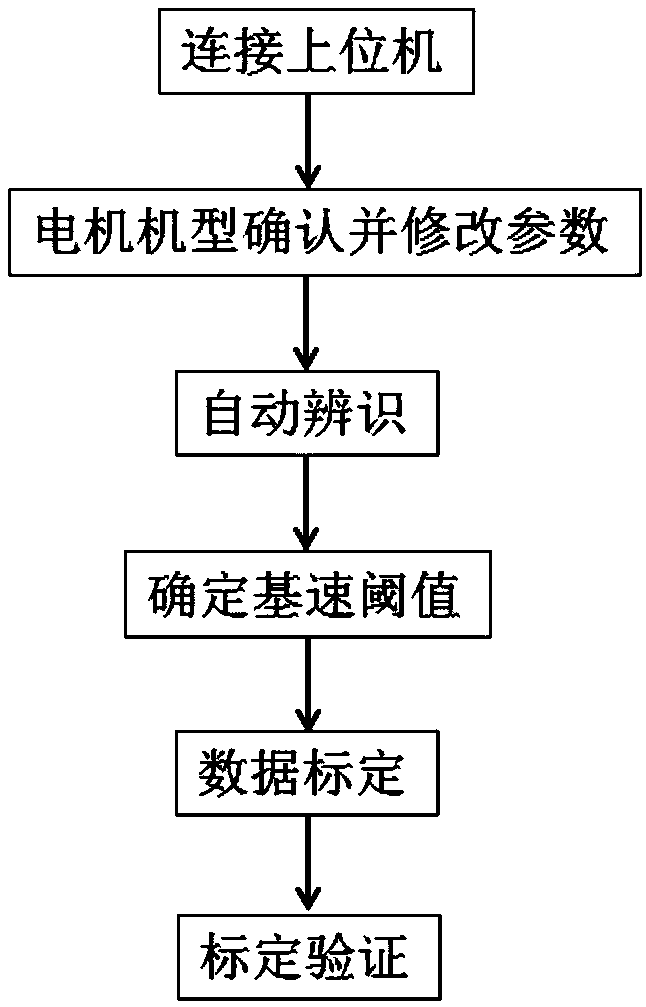

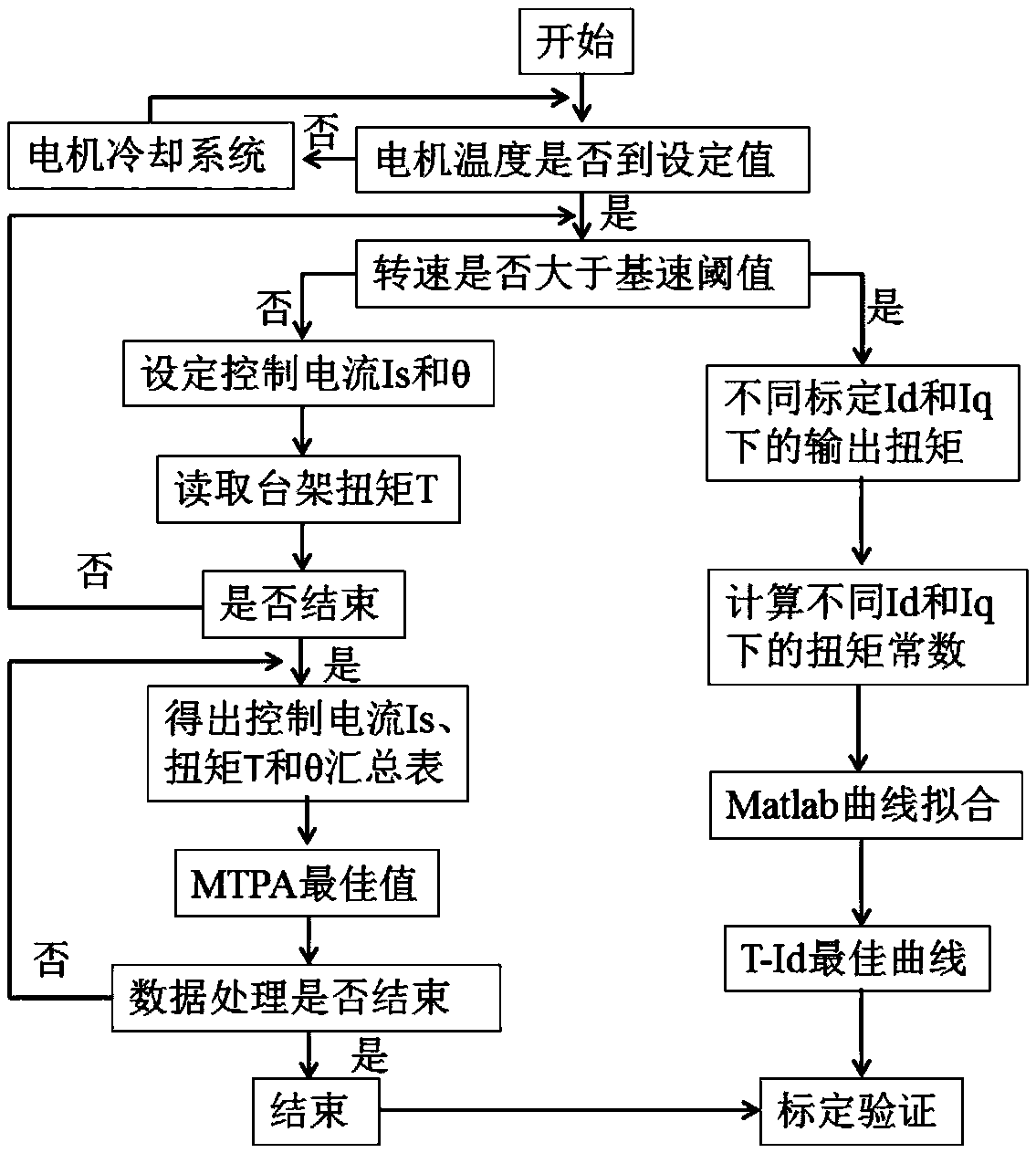

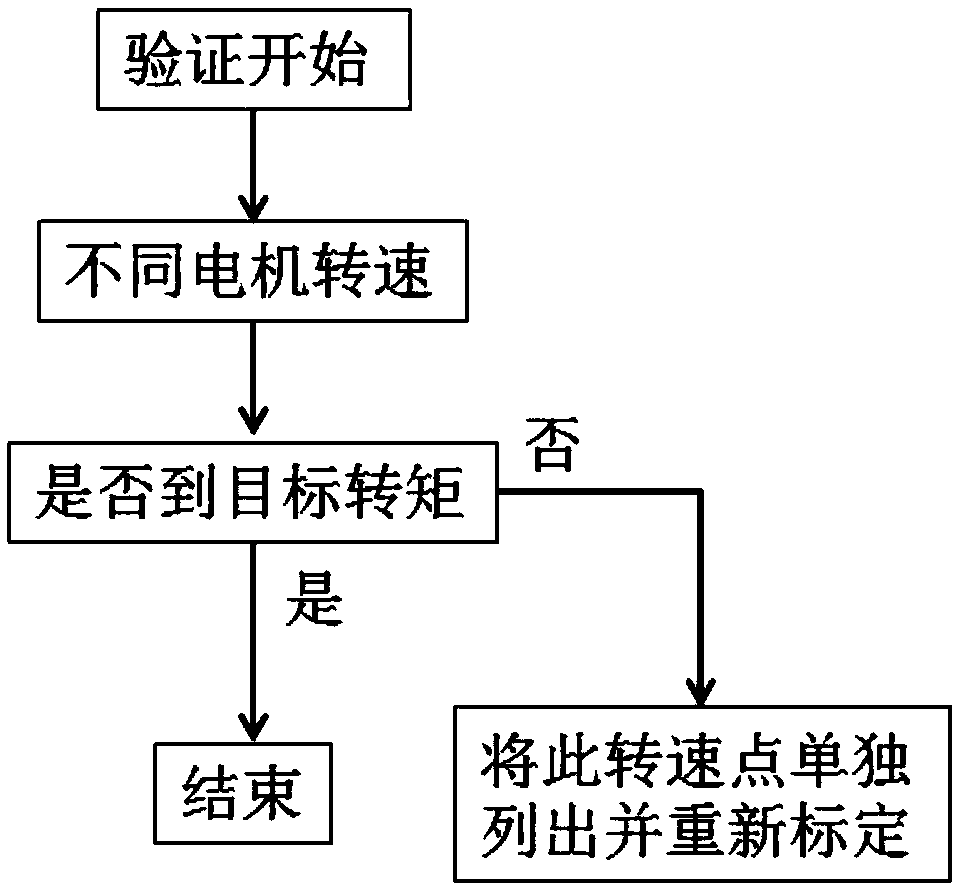

[0022] figure 1 The general flow chart of the motor calibration of the present invention is simply shown. Firstly, the upper computer is connected with the dynamometer, the motor controller and the motor cooling system, and the address is modified according to the communication protocol between the motor and the motor controller, and the motor model is confirmed. Modify relevant technical parameters according to the motor technical agreement. Afterwards, automatic identification is carried out to learn the angle of the rotor and the resolver, and when the motor enters the field-weakening zone when the speed is judged, it is necessary to fine-tune the angle so that the torque of the motor does not change much before and afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com