A flexible structure and design method for rocket engine thrust fidelity measurement

A rocket engine and flexible structure technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve the problems of small radial stiffness, engine offset obstruction, inaccurate experimental results, etc., and achieve easy radial The effect of deflection, radial stiffness reduction, and accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments

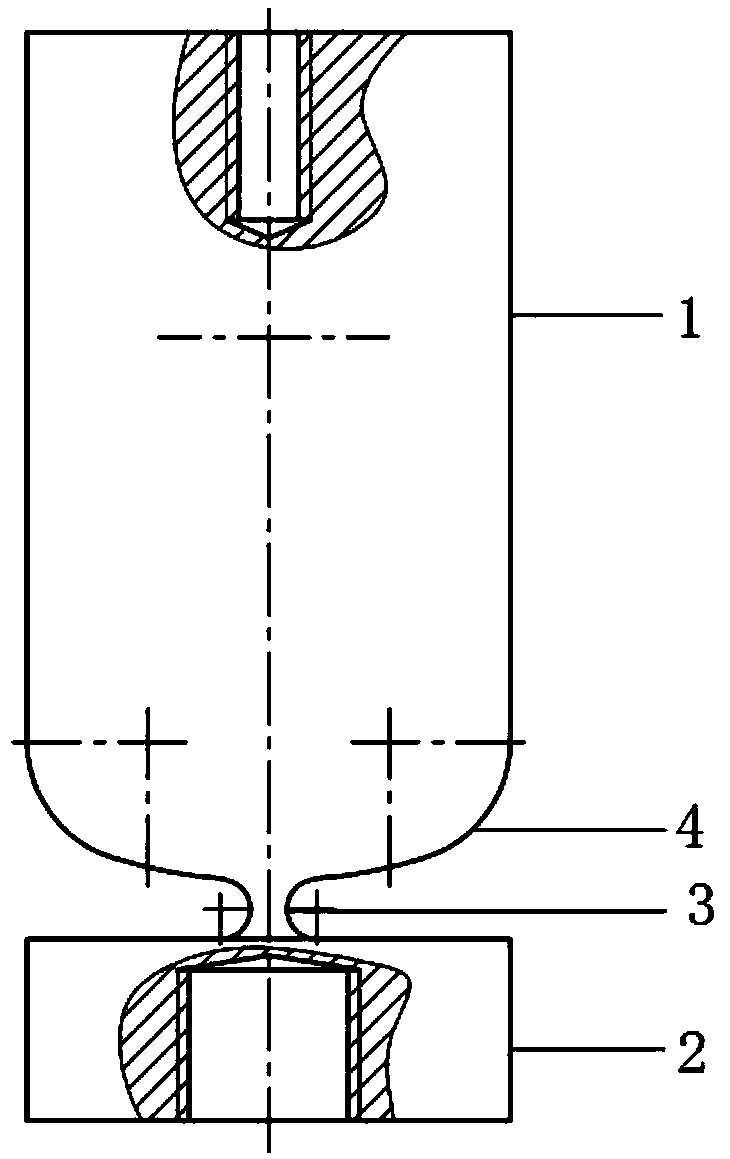

[0031] like figure 1 As shown, a flexible structure for fidelity measurement of thrust of a rocket engine includes an upper body 1 of a long cylindrical structure, the lower end of the upper body 1 is connected with the upper end of a transition body 4, and the transition body 4 is a structure approximately half an ellipsoid , the lower end of the transition body 4 is connected with the upper end of the weak body 3, the weak body 3 is a rotary structure formed by two arcs rotating around the axis, the lower end of the weak body 3 is connected with the top of the lower body 2, and the lower body 2 is a flat cylindrical structure.

[0032] The material of the upper body 1 , the transition body 4 , the weak body 3 and the lower body 2 is spring steel.

[0033] The diameter ratio of the weak body 3 to the upper body 1 or the lower body 2 is 3:40. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com