Powder spraying room for electrostatic spraying

A technology of electrostatic spraying and powder spraying room, which is applied in the direction of spray paint booth and spraying device, which can solve the problems of unfavorable powder spraying quality, single powder spraying treatment of workpieces, unfavorable powder quality assurance of workpieces, etc., so as to ensure the quality of powder spraying and avoid pollution environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

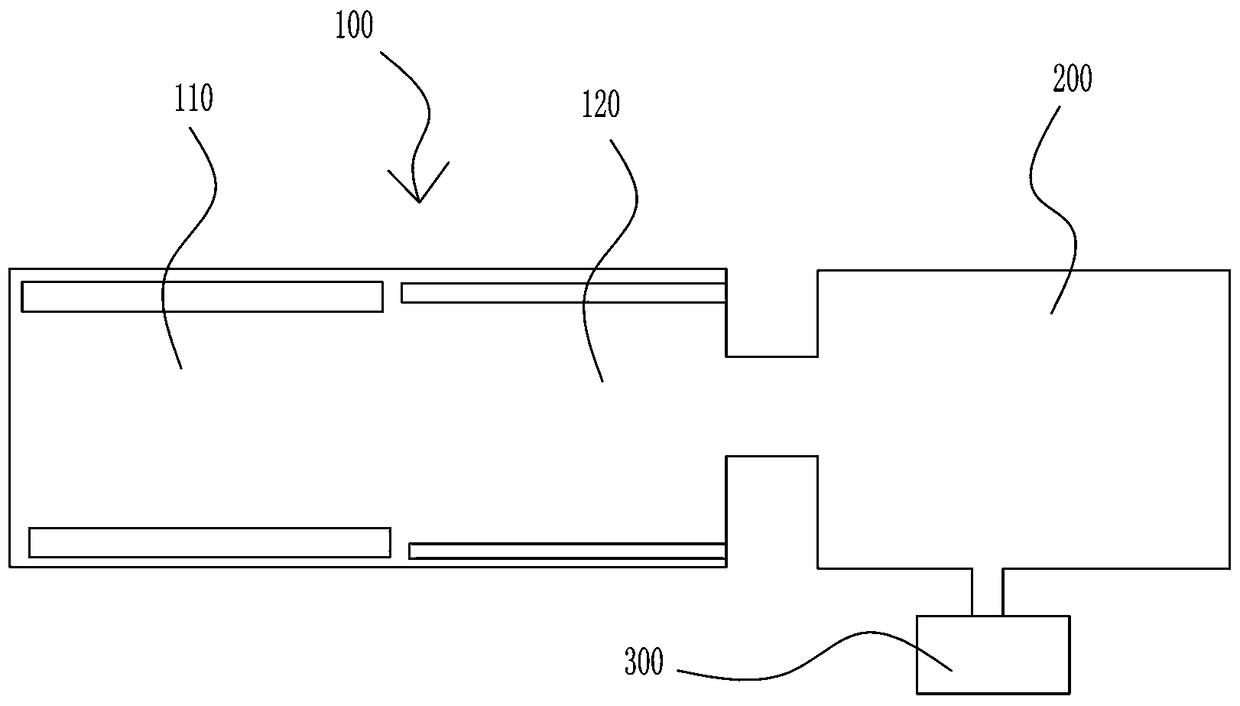

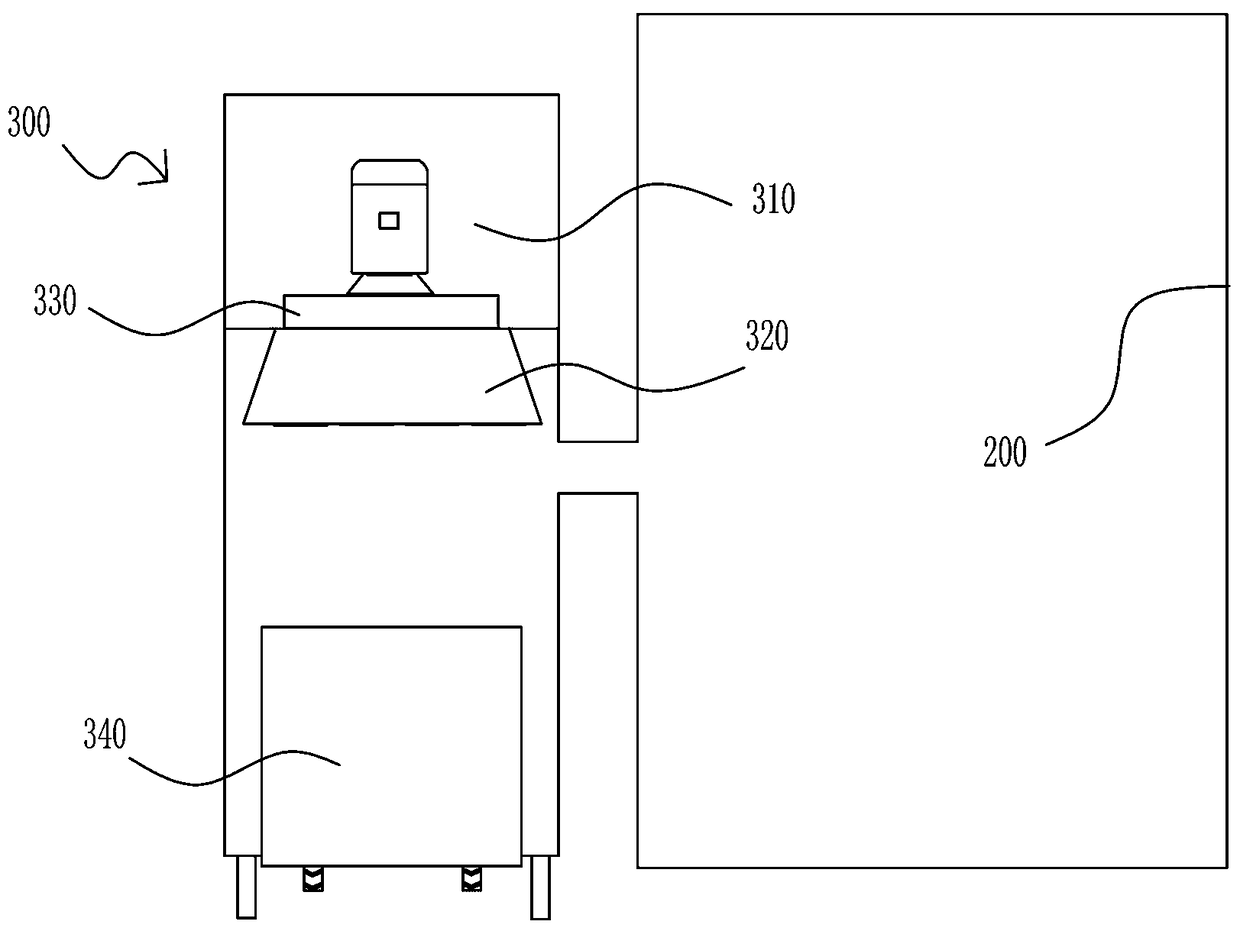

[0026] Such as figure 1 , figure 2 As shown, this embodiment provides a powder spray booth for electrostatic spraying, including a first room structure 100 and a second room structure 200, the first room structure 100 and the second room structure 200 are two independent The room structure, the two are connected to each other, but the channel diameter needs to be set as small as possible, only for the transportation and circulation of workpieces, the suspension conveyor chain in the prior art is set in the first room structure 100 and the second room structure 200 top, while the tops of the first room structure 100 and the second room structure 200 are only provided with small openings that can be placed and transported by hooks, and the hanging conveyor chain can also be fixed on the first room structure 100 and the second Below the top of the room structure 200, the suspension conveyor chain is located in the room to avoid the opening of small openings;

[0027] The first...

Embodiment 2

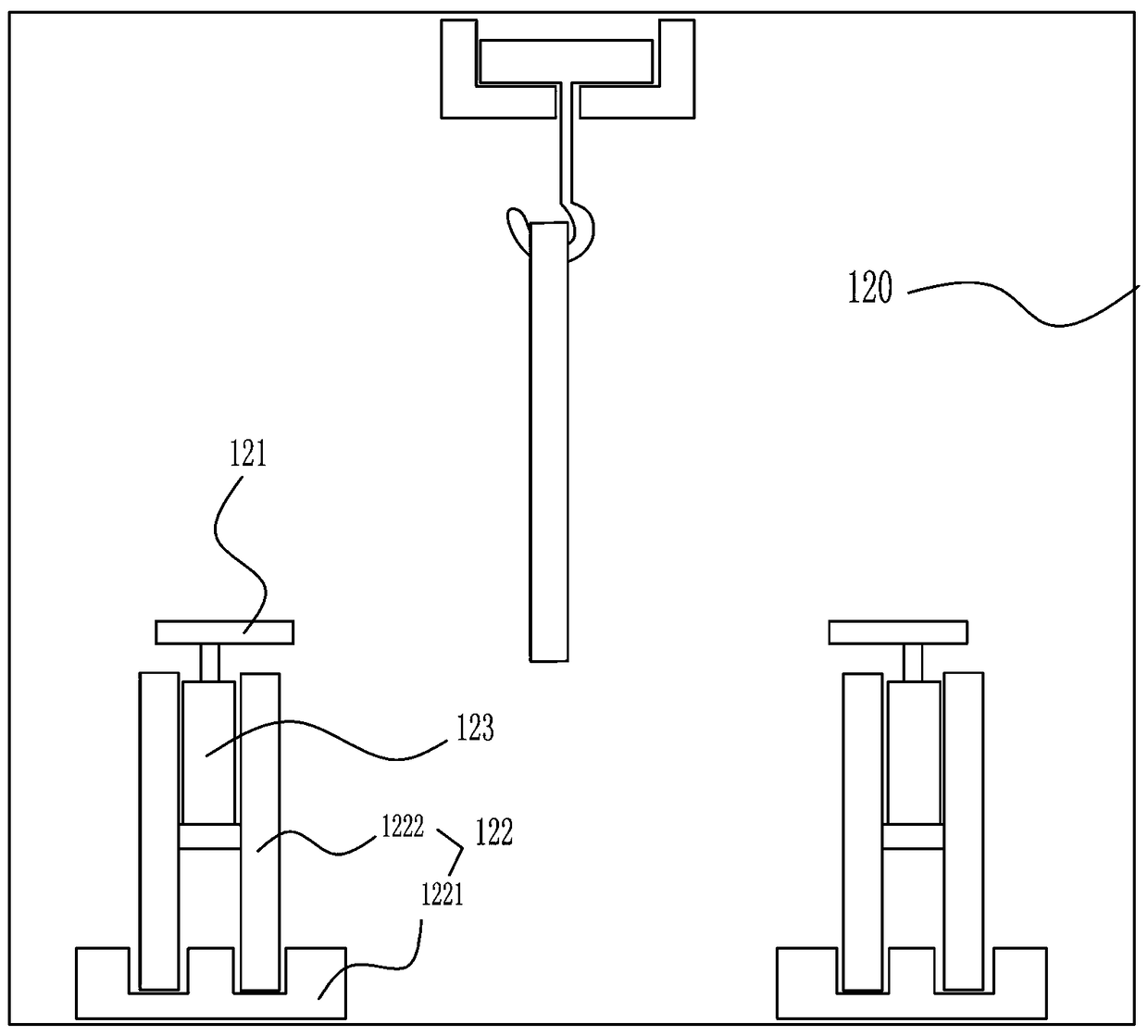

[0032] Such as image 3As shown, the difference between this embodiment and Embodiment 1 is that the re-spray area 120 is provided with a powder spray gun 121, which is used to drive the powder spray gun 121 along the extension direction of the re-spray area 120 (same as the workpiece transportation direction). ) moving mechanism 122 and a lifting mechanism 123 for driving the powder spraying gun 121 up and down. The powder spray gun 121 , the moving mechanism 122 and the lifting mechanism 123 are provided on both sides of the respray area 120 so as to perform respray operation on both sides of the workpiece at the same time. The powder spray gun 121 is connected with an air pump and a powder supply bucket through a powder pipeline, and the air pump is used to pump the powder in the powder supply bucket into the powder pipeline for the powder spray gun 121 to spray. The above-mentioned design, through the adjustment of the moving mechanism 122 and the lifting mechanism 123, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com