Surface transfer printing process of three-dimensional paper pulp molded product

A technology of pulp molding and products, which is applied in the printing process, the process for producing decorative surface effects, printing of special varieties of printed matter, etc., can solve the problems of poor visual effect and process finishing, and achieve beautiful appearance, Good visual effect and good tactile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

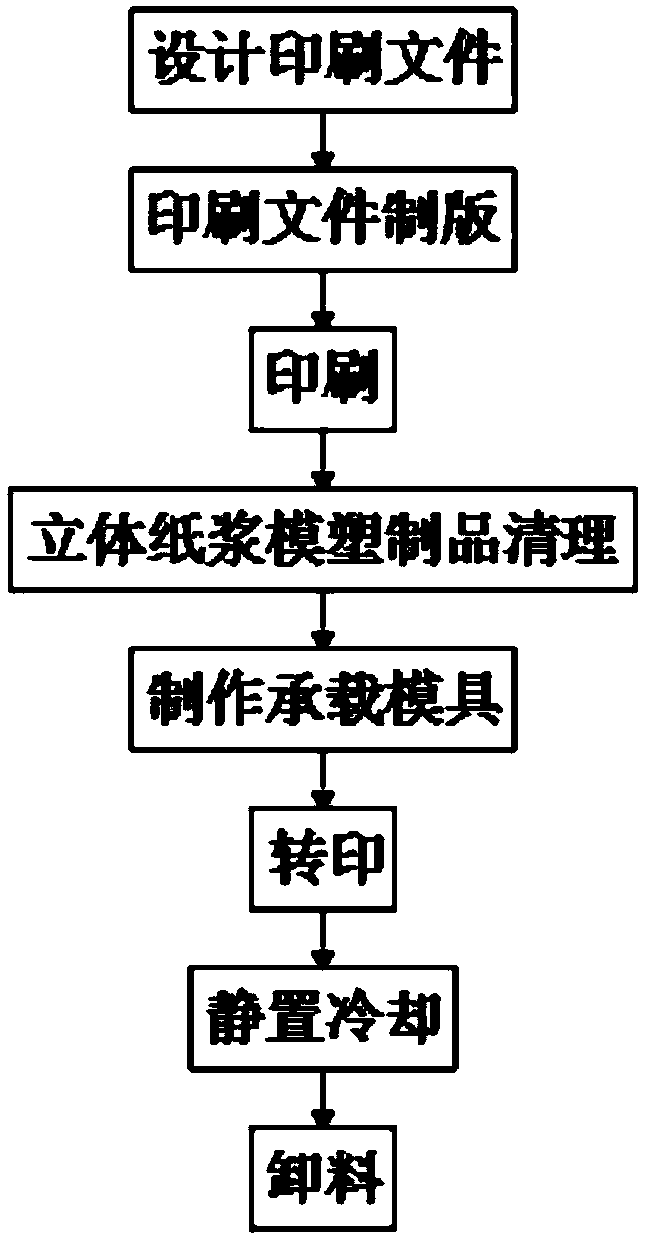

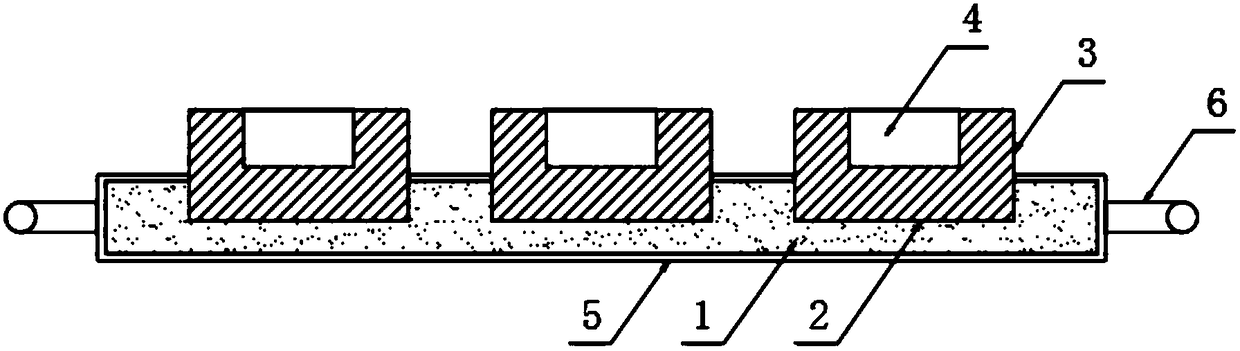

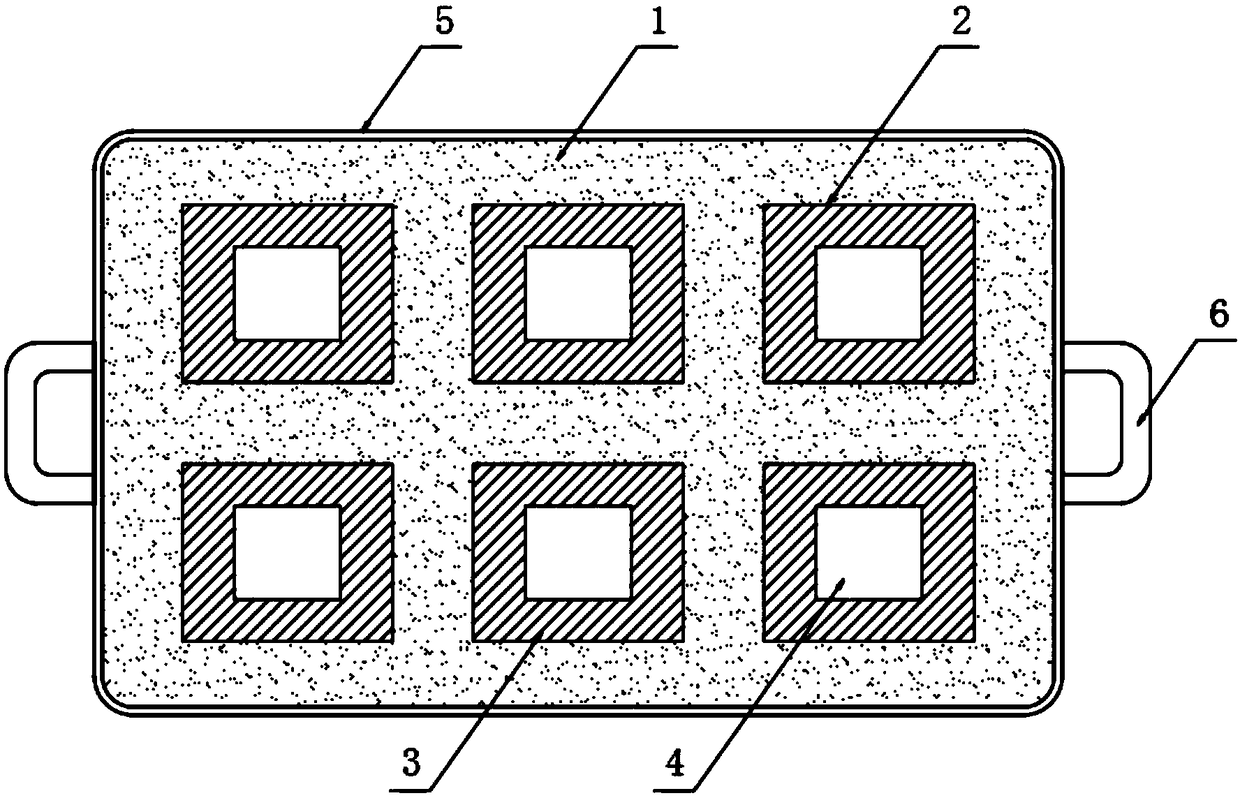

[0032] The present invention provides such Figure 1-3 A three-dimensional pulp molding product surface transfer printing process shown specifically includes the following steps:

[0033] Step 1. Design printing documents: Design various color graphics and text schemes according to the shape of the three-dimensional pulp molding product and customer requirements, and finally select the final scheme from various schemes;

[0034] Step 2, printing document plate-making: then use plate-making equipment to print document plate-making according to one of the final schemes selected in the above steps, so as to make a printing plate;

[0035] Step 3, printing: then print the printing plate prepared in the above step 2 onto the thermal transfer film, and then leave the thermal transfer film for 30 minutes after printing;

[0036] Step 4. Cleaning of three-dimensional pulp molded products: Using the principle of neutralization of ion wind and static electricity, use ion air gun to rem...

Embodiment 2

[0044] The present invention provides such Figure 1-3 A three-dimensional pulp molding product surface transfer printing process shown specifically includes the following steps:

[0045] Step 1. Design printing documents: Design various color graphics and text schemes according to the shape of the three-dimensional pulp molding product and customer requirements, and finally select the final scheme from various schemes;

[0046] Step 2, printing document plate-making: then use plate-making equipment to print document plate-making according to one of the final schemes selected in the above steps, so as to make a printing plate;

[0047] Step 3, printing: then print the printing plate prepared in the above step 2 onto the thermal transfer film, and then leave the thermal transfer film for 40 minutes after printing;

[0048] Step 4. Cleaning of three-dimensional pulp molded products: Using the principle of neutralization of ion wind and static electricity, use ion air gun to rem...

Embodiment 3

[0056] The present invention provides such Figure 1-3 A three-dimensional pulp molding product surface transfer printing process shown specifically includes the following steps:

[0057] Step 1. Design printing documents: Design various color graphics and text schemes according to the shape of the three-dimensional pulp molding product and customer requirements, and finally select the final scheme from various schemes;

[0058] Step 2, printing document plate-making: then use plate-making equipment to print document plate-making according to one of the final schemes selected in the above steps, so as to make a printing plate;

[0059] Step 3, printing: then print the printing plate prepared in the above step 2 onto the thermal transfer film, and then leave the thermal transfer film for 50 minutes after printing;

[0060] Step 4. Cleaning of three-dimensional pulp molded products: Using the principle of neutralization of ion wind and static electricity, use ion air gun to rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com