Locomotive rail-coated nozzle fixing device

A technology for coating nozzles and fixing devices, which is applied to the equipment fixed on the vehicle, transportation and packaging, railway car body parts, etc. It can solve the problem of excessive friction at the contact position between the wheel and the curved rail, and the difficulty in adjusting the position accuracy of the nozzle position , affect the service life of rails and wheels, and achieve the effect of convenient and reliable positioning adjustment, meeting precision requirements, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions in the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described The embodiments are only some of the embodiments of the present invention, not all of them.

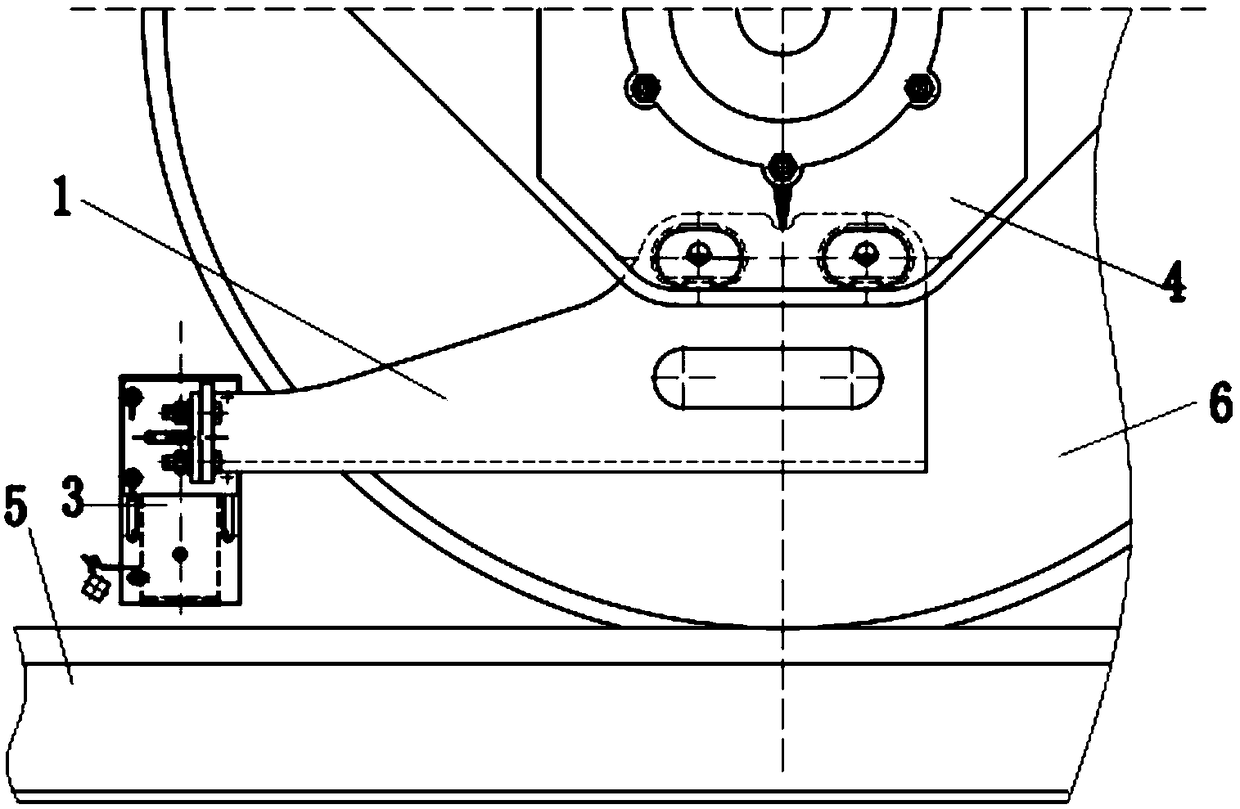

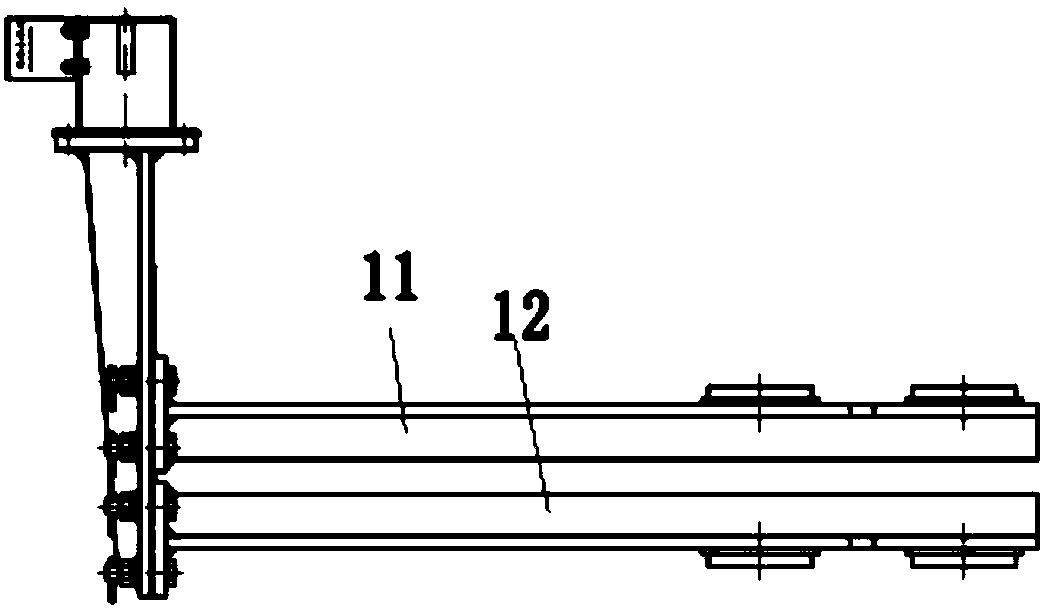

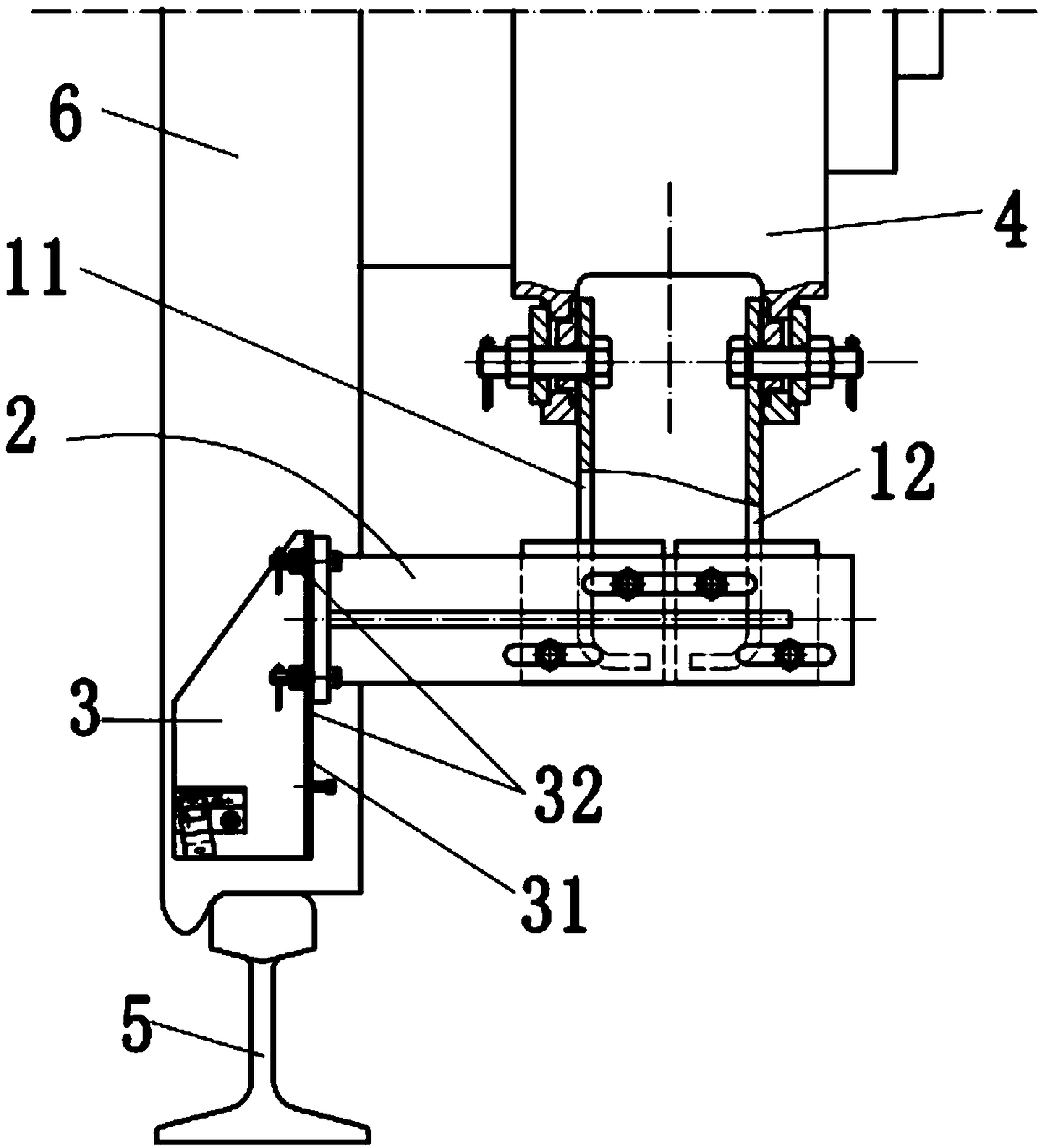

[0035] Such as Figure 1-9 As shown, a rail coating nozzle fixing device for a locomotive includes a left and right support assembly 1, a lateral support assembly 2, and a nozzle box 3. The left and right support assembly 1 includes a left support seat 11 and a right support seat 12. The left support The upper part of the seat 11 is connected with the inner side of the left side of the locomotive wheel bearing body 4 through a combination of bolts and nuts; the upper part of the right support seat 12 is connected with the inner side of the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com