Formula of insulating wire sheath

A wire sheath and formula technology, applied to organic insulators, plastic/resin/wax insulators, etc., can solve the problems of easy damage, environmental pollution of insulating rubber, etc., and achieve the effects of less pollution, avoiding burning, and effective heat dissipation

Inactive Publication Date: 2018-12-18

YUEXI SWAN ELECTRONICS TECH

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Most of the existing insulating rubbers used in the above work have the disadvantages of serious environmental pollution and easy damage.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

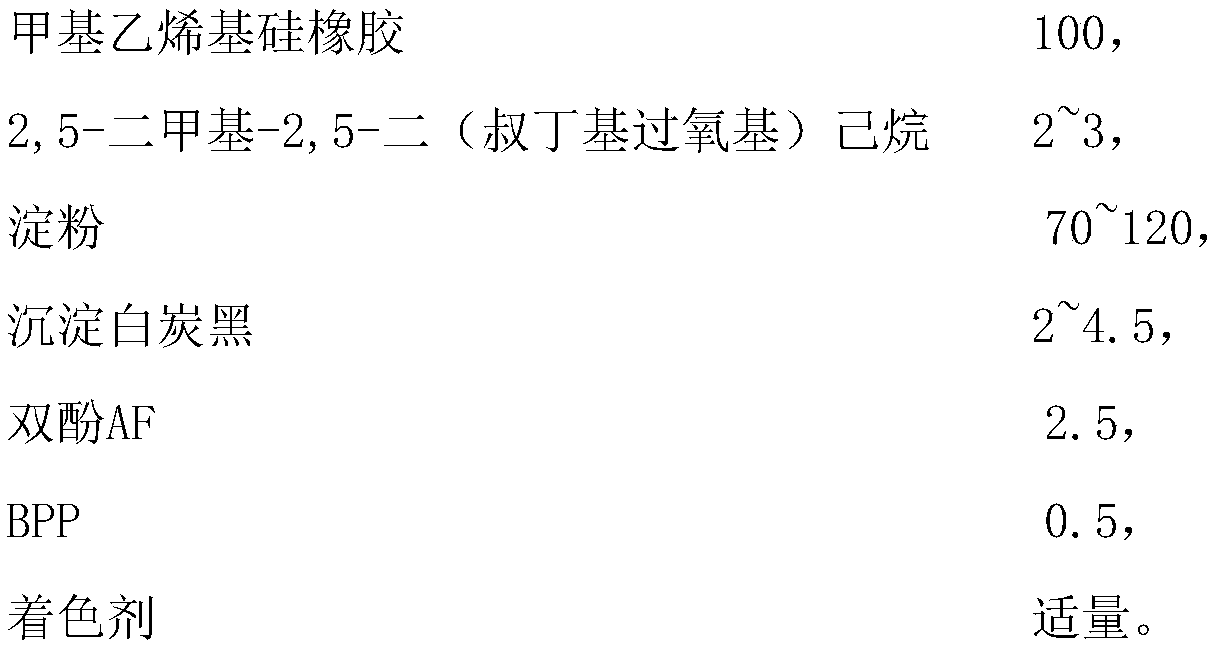

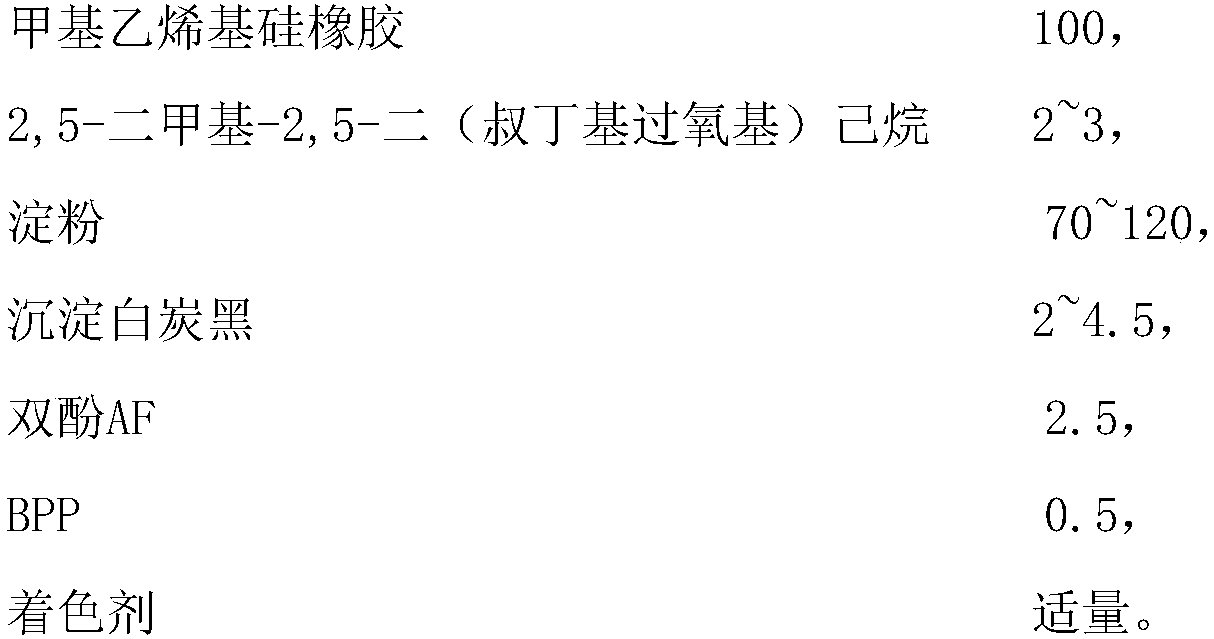

[0014] The composition and the mass parts of each composition of described laser engraving rubber sheet sizing material formula are:

[0015]

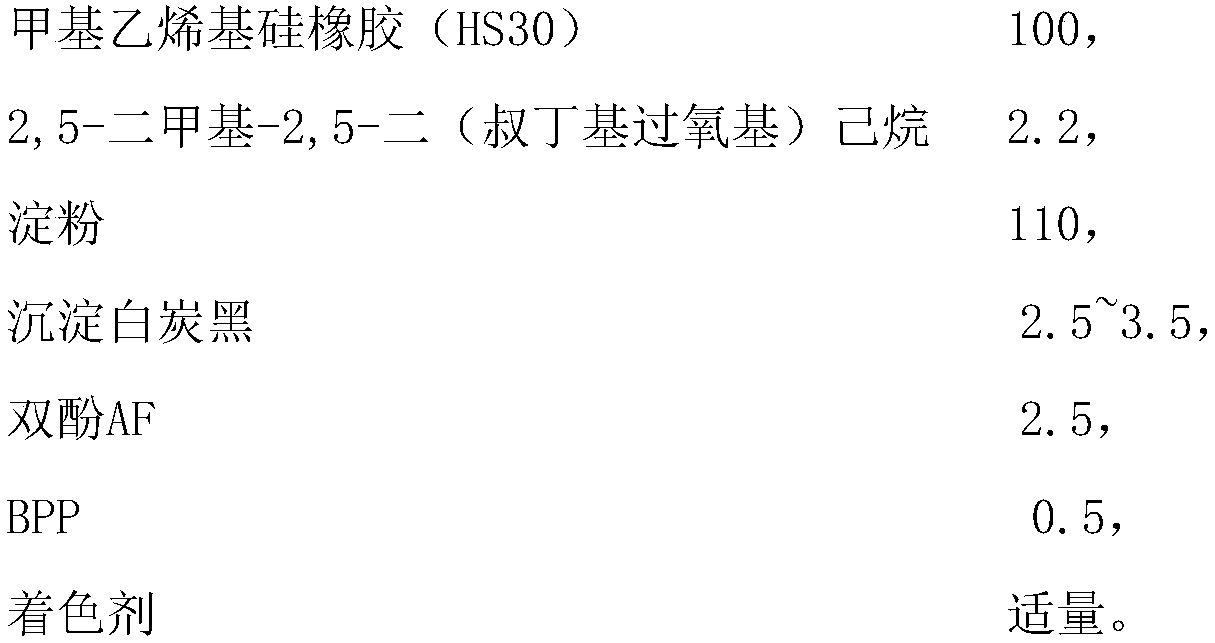

Embodiment 2

[0017] The composition and the mass parts of each composition of described laser engraving rubber sheet sizing material formula are:

[0018]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a formula of a wire sheath, and concretely relates to a formula of an insulating wire sheath. The formula of the insulating wire sheath comprises, by mass, 100 parts of methylvinyl silicone rubber, 2-3 parts of 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, 70-120 parts of starch, 2-4.5 parts of precipitated silica, 2.5 parts of bisphenol AF, 0.5 part of BPP and an appropriate amount of a coloring agent. The methylvinyl silicone rubber is adopted as raw rubber, and the starch and a very small amount of the precipitated silica are adopted as a filler, so the insulating wire sheath has small pollution to the surrounding environment and can effectively dissipate heat to avoid burnout of a circuit in the use process.

Description

technical field [0001] The invention relates to a wire sheath formula, in particular to an insulated wire sheath formula. Background technique [0002] Insulating rubber is widely used in substations, power plants, power distribution rooms, laboratories and field live work, etc., with good physical and mechanical properties, and can work in environments with high dielectric coefficient requirements in dry -35°C-+100°C air. Most of the existing insulating rubbers used in the above work have the disadvantages of serious environmental pollution and easy damage. Contents of the invention [0003] The purpose of the present invention is to overcome the above-mentioned shortcomings, and propose a sheath of an insulated wire that has little environmental pollution, long service life and is not easily damaged. [0004] The present invention is realized by the following method. [0005] The composition of an insulated wire sheath formula and the mass parts of each composition are...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L3/02C08L83/07C08K13/02C08K5/14C08K3/36C08K5/136H01B3/46H01B3/18

CPCC08L3/02C08L2203/202H01B3/18H01B3/46C08L83/04C08K13/02C08K5/14C08K3/36C08K5/136

Inventor 储劲松肖友朋

Owner YUEXI SWAN ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com