Thermal treatment method for high-nitrogen high-corrosion-resistance plastic mould steel

A technology of plastic mold steel and heat treatment method, applied in heat treatment equipment, manufacturing tools, quenching agent, etc., can solve the problems of high cost, unsatisfactory corrosion resistance, expensive alloy elements of plastic mold steel, etc., and achieve low production cost, durable The effect of excellent corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The die steel in Example 1 is obtained by forging a steel ingot, the cross-sectional size is 100mm (thick) × 600mm (wide), and the chemical composition of the die steel is C 0.37%, Si 0.32%, Mn 0.55%, Cr 13.3%, Ni 0.18% , Mo 0.06%, N0.07%, P 0.022%, S 0.004%, and the rest is Fe.

[0031] (1) Spheroidizing annealing

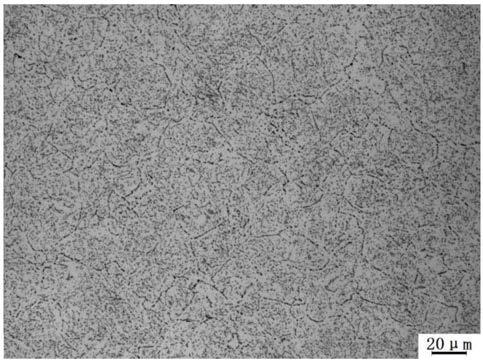

[0032] Put the mold steel from room temperature into the annealing furnace, raise the temperature to 960°C at a rate of 100°C / h, keep it for 10 hours, then cool it to 740°C at a cooling rate of 40°C / h, keep it for 7 hours, and finally, heat it at 40°C / h The cooling rate is cooled to 500°C, and the furnace is air-cooled to room temperature. The obtained metallographic structure is as follows: figure 1 shown.

[0033] (2) Salt bath quenching

[0034] Put the spheroidized annealed die steel obtained in step (1) into the quenching furnace at room temperature, and raise the temperature to 750±10°C at a rate of 100°C / h, keep it warm for 3.5h, and continue to p...

Embodiment 2

[0039] In Example 2, the die steel is obtained by forging a steel ingot, the section size is 100 mm (thick) × 600 mm (wide), and the chemical composition of the die steel is C 0.33%, Si 0.320%, Mn 0.52%, Cr 13.8%, Ni 0.16% , Mo 0.05%, N0.065%, P 0.022%, S 0.004%, and the rest is Fe.

[0040] (1) Spheroidizing annealing

[0041] Put the mold steel from room temperature into the annealing furnace, raise the temperature at a rate of 90 °C / h to 950 °C, keep it for 9 hours, then cool it at a cooling rate of 40 °C / h to 740 °C, keep it for 6 hours, and finally, at 40 °C / h The cooling rate is cooled to 500°C, and the furnace is air-cooled to room temperature. The obtained metallographic structure is as follows: figure 1 shown.

[0042] (2) Salt bath quenching

[0043] Put the spheroidized annealed die steel obtained in step (1) into the quenching furnace at room temperature, and raise the temperature to 750±10°C at a rate of 90°C / h, keep it warm for 3.5h, and continue to press 90°C / h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impact energy | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com