A floating raft roadbed structure

A technology of floating rafts and subgrades, which is applied in the direction of infrastructure engineering, roads, roads, etc., and can solve the problems of outage trains, difficult handling, and high economic costs, and achieve the effects of reducing weight, avoiding additional deformation, and ensuring normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

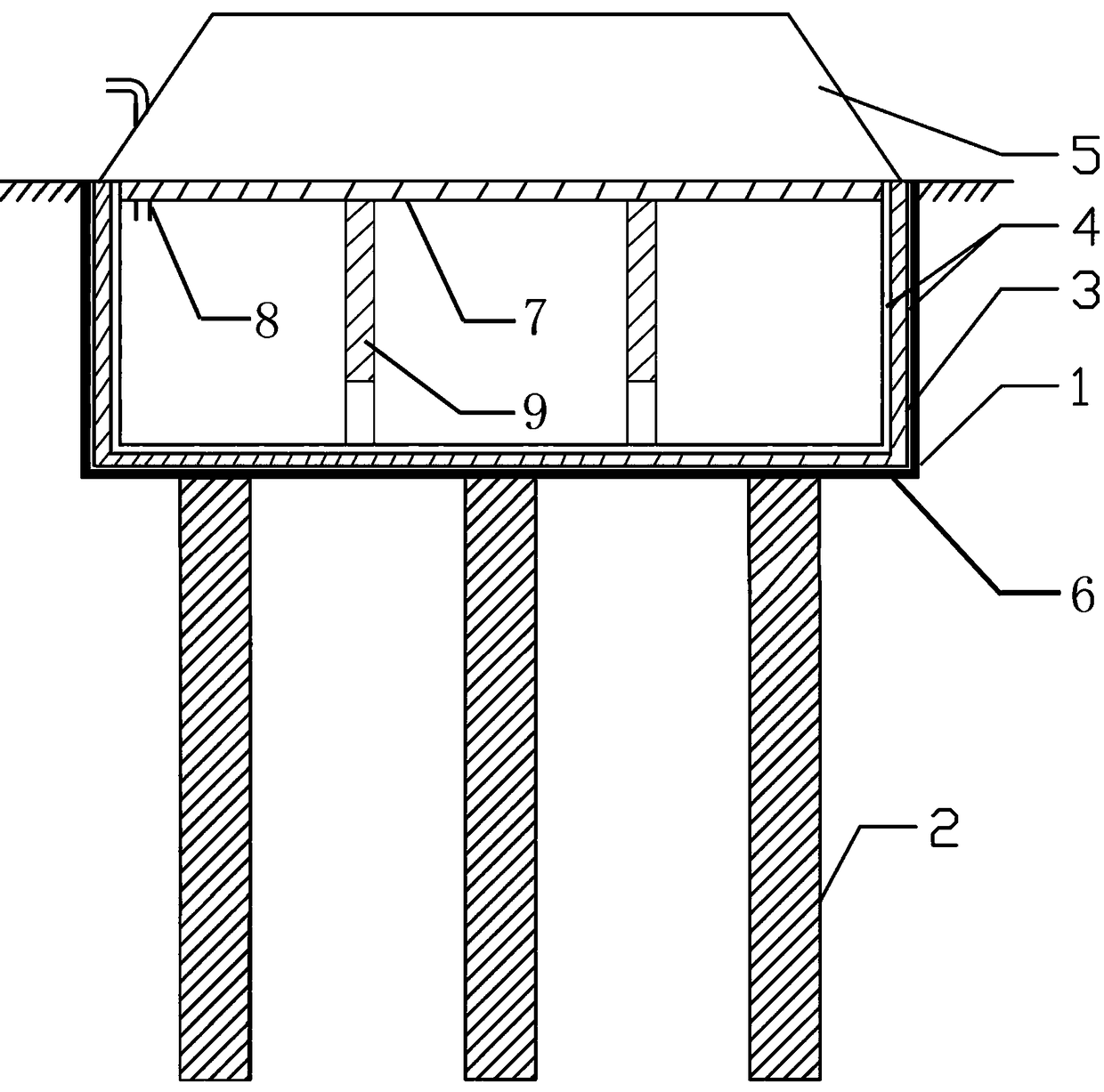

[0017] Such as figure 1 in,

[0018] A floating raft type roadbed structure, including a floating raft box 3, the floating raft box 3 is buried in a foundation pit 1, and foundation treatment piles 2 are arranged under the foundation pit 1, and the top of the floating raft box 3 is filled Subgrade 5.

[0019] In a preferred solution, geotextile 6 is laid around the foundation pit 1.

Embodiment 2

[0021] On the basis of embodiment 1, the floating raft box 3 adopts a hollow concrete box structure, and the floating raft box 3 is provided with a plurality of vertical partitions 9 on the top of the floating raft box 3 for supporting the roadbed. The concrete slab 7 of 5 and the waterproof layer 4 are provided on the inner and outer walls of the pontoon 3.

Embodiment 3

[0023] On the basis of Example 1, the concrete slab 7 is provided with an air duct 8, one end of the air duct 8 is located in the floating raft box 3, and the other end passes through the roadbed 5 and extends to the outside of the roadbed 5.

[0024] Example 3:

[0025] On the basis of Example 1, the inner wall of the pontoon 3 is made of metal or organic composite materials. The adopted metal-based composite material can realize the floatation of the pontoon under the buoyancy of the water in the pontoon 3, so as to achieve the purpose of lifting the roadbed 3 with the amount of filling and drainage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com