Large-volume concrete floor reinforcement supporting system and construction method thereof

A large-volume concrete and support system technology, applied in excavation, artificial islands, water conservancy projects, etc., can solve the problems of cumbersome disassembly and assembly of steel pipe frames, high efficiency, high risk of dismantling, etc., and achieve simple and easy construction methods and support High safety and good for construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

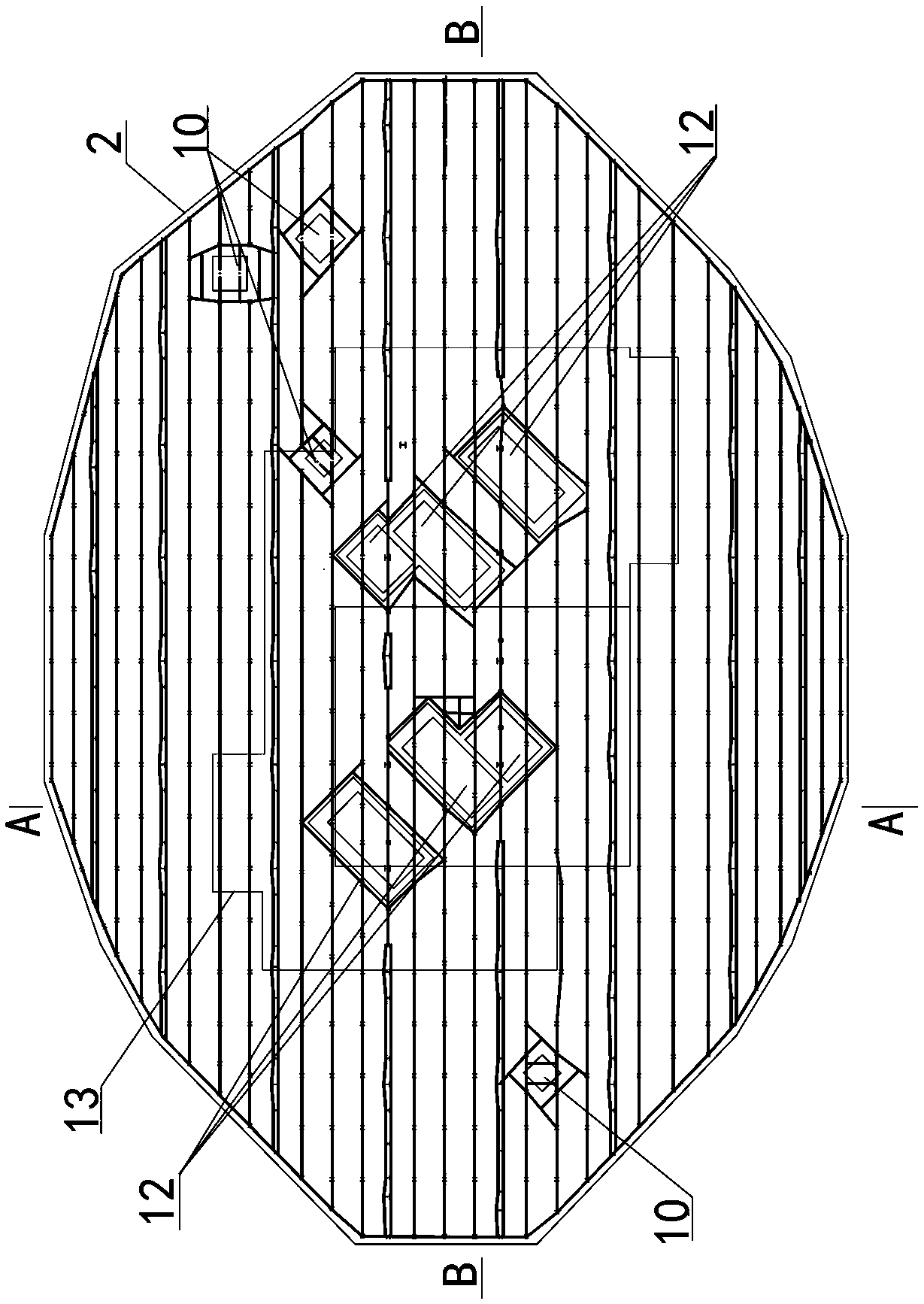

[0043] see example figure 1 As shown, a foundation pit 2 of a mass concrete floor to be poured is shown in the figure. The foundation pit includes a normal area and a deep pit area 13 in the middle of the foundation pit, and there are 4 water collecting wells and 6 elevator shafts distributed in the foundation pit. .

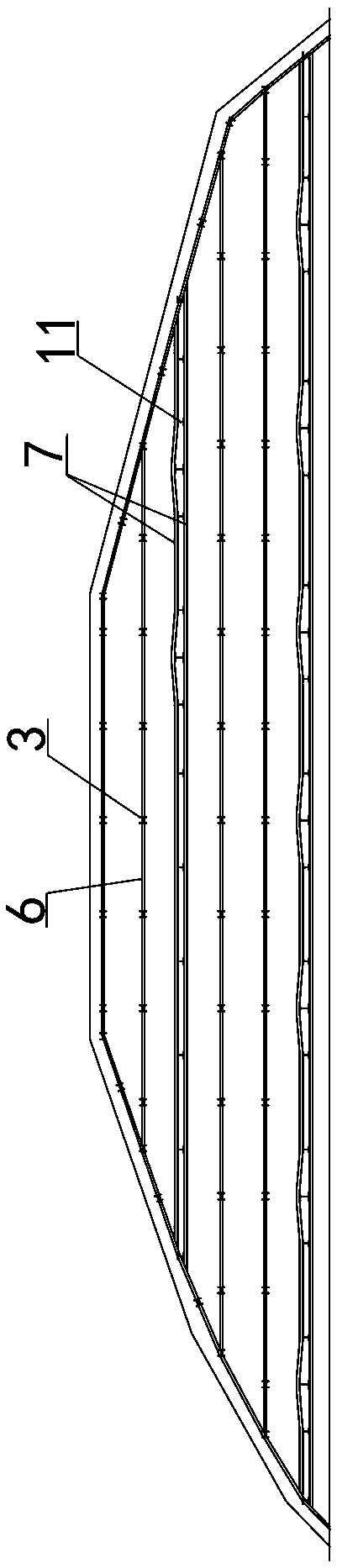

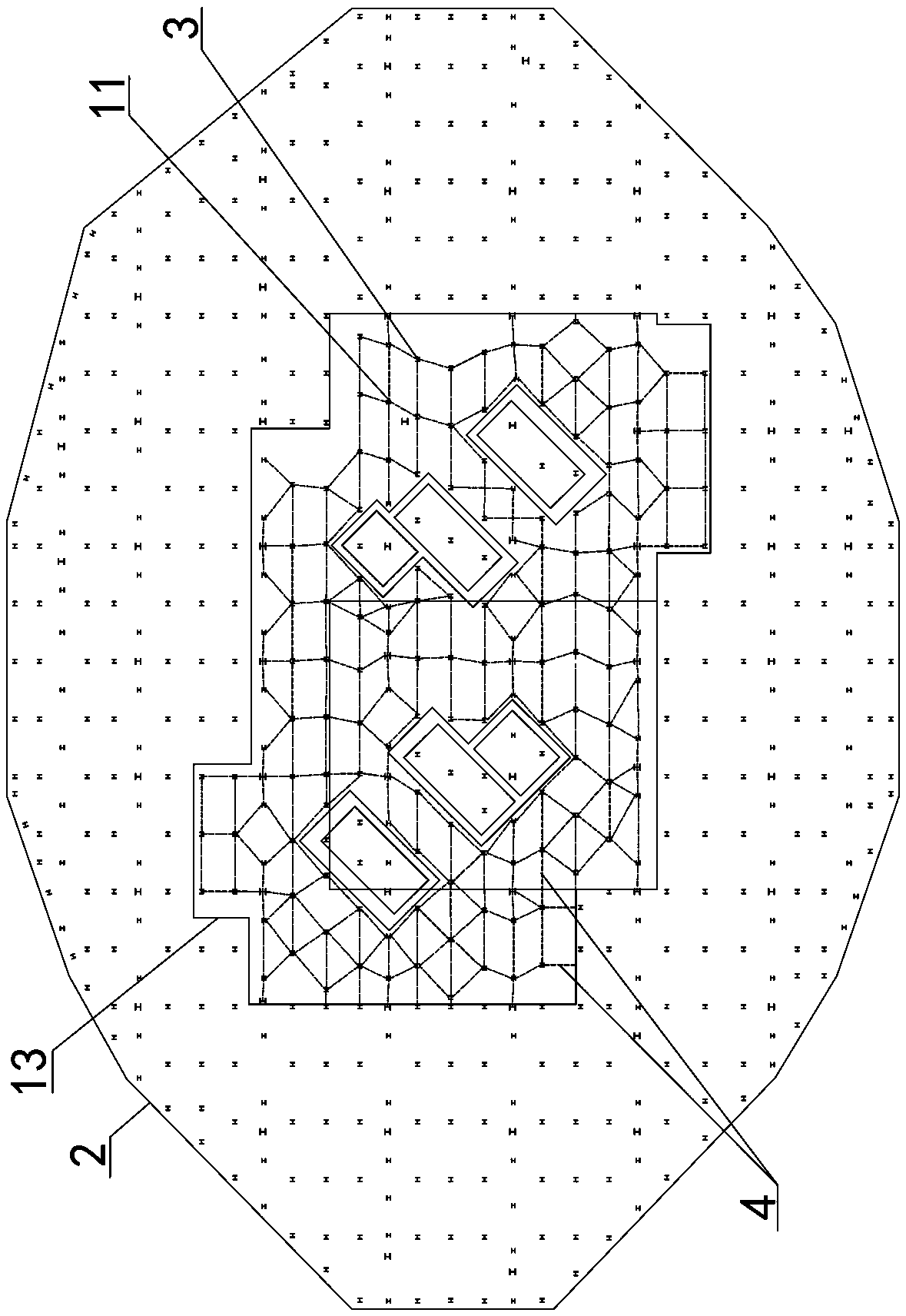

[0044] see Figure 2-7 As shown, this large-volume concrete floor reinforcement support system includes a floor lower-layer steel bar 1 arranged above the inner bottom formwork of the foundation pit and an inner support steel column 11 supported by the foundation pit that is fixed at intervals and stands on the upper surface of the lower floor steel bar 1, The bottoms of the vertical supports are all centrally and fixedly connected with a bottom connecting plate 31 , and the lower side of the bottom connecting plate 31 is fixedly connected with the upper side of the lower layer reinforcing bars 1 of the bottom plate. A top connecting plate 32 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com