Construction method for one-time pouring forming of concrete flanging

A construction method and concrete technology, which is applied in the processing of building materials, the preparation of building components on site, construction, etc., can solve the problems of easy run-out of hanging molds, difficult fixing, backwater, etc., and improve construction accuracy and quality , save the work of removing steel bars and simplify the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] The present invention will be further described in detail below in conjunction with an integral pouring construction template for the toilet anti-sill and its construction method.

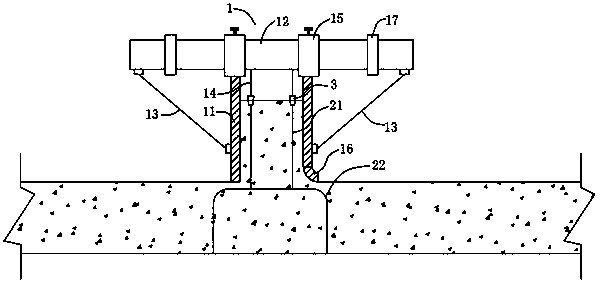

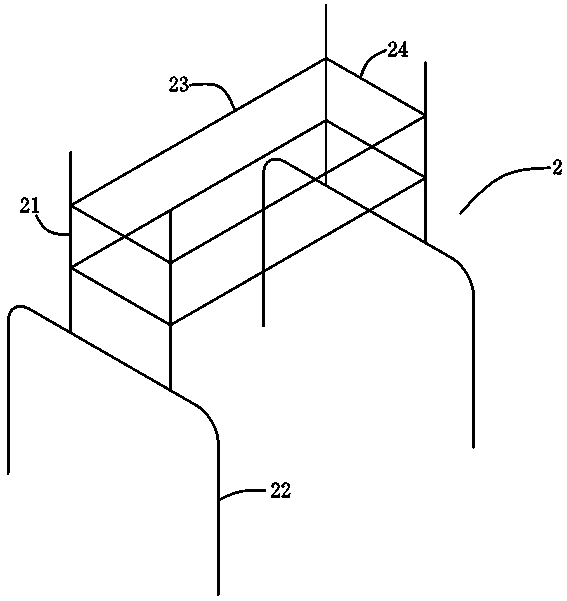

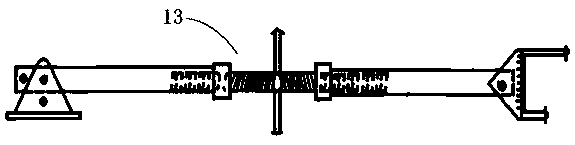

[0031] When implementing: Figure 1 ~ Figure 5 As shown, an integrated pouring construction formwork structure for toilet anti-sills includes a template assembly 1 and a support assembly 2 for supporting the template assembly 1. The template assembly 1 includes side wall templates located on both sides of the anti-sill to be poured in the width direction 11, and a beam 12 fixedly connected above the two side wall templates 11; the support assembly 2 includes a support rib 21 vertically arranged between the two side wall templates 11, the support rib 21 The lower end is fixedly connected to the main concrete reinforcement, and the upper end is fixedly supported under the beams 12, and at least two supporting ribs 21 are arranged along the length direction under each beam 12; the side wall formwo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com