Hydraulic support platform stand column oil cylinder system controlled by proportional servo valve and pressure control method

A proportional servo valve, hydraulic support technology, applied in the direction of fluid pressure actuation system components, servo motors, servo meter circuits, etc., can solve problems such as unfavorable control performance, internal/external interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

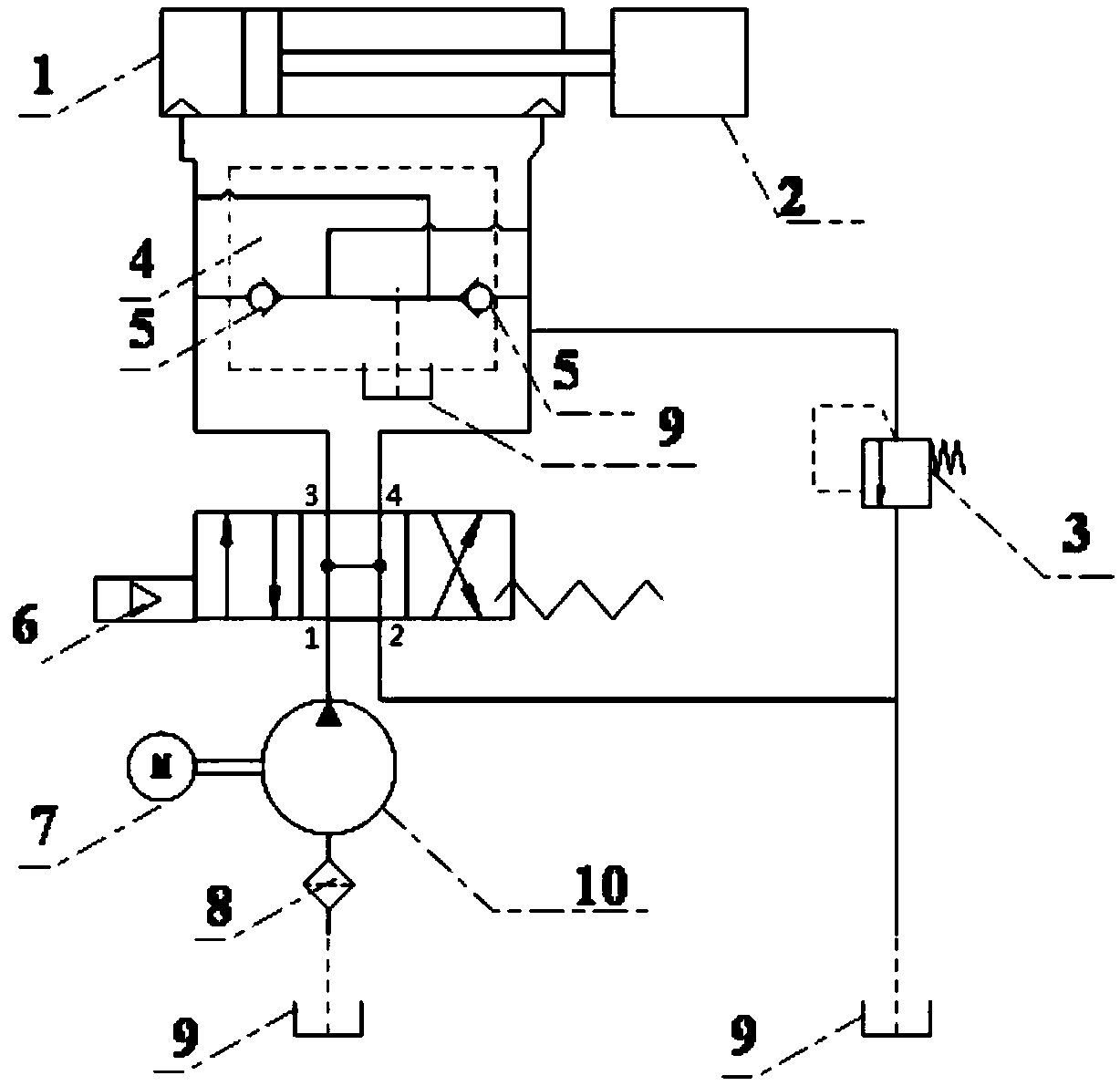

[0089] Example 1: figure 1 In the process of fully mechanized excavation of the roadway, when the advancing distance of the roadheader reaches the maximum empty head distance, the roadheader stops working, and the hydraulic support platform performs the boosting support process. Hydraulic support platform such as Figure 5 As shown, four independent proportional servo valves are used to control the pressure of four sets of column cylinders respectively, and the upper ends of the four sets of column cylinders are connected with longitudinal beams 11 and crossbeams 12; start the power supply, according to the initial support force required for the temporary support of the roof, after After the controller is adjusted, the column oil cylinder reaches the rated initial support force.

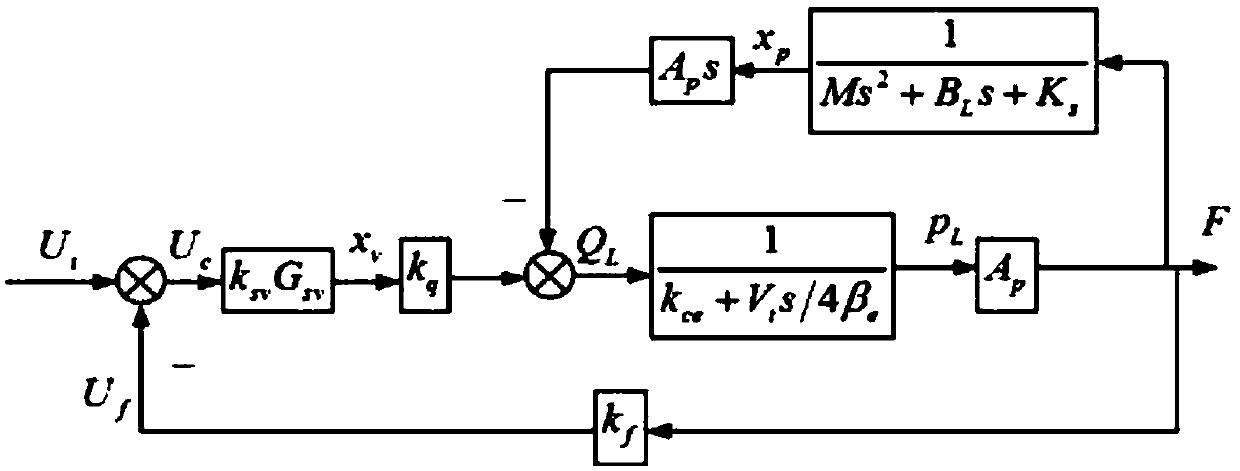

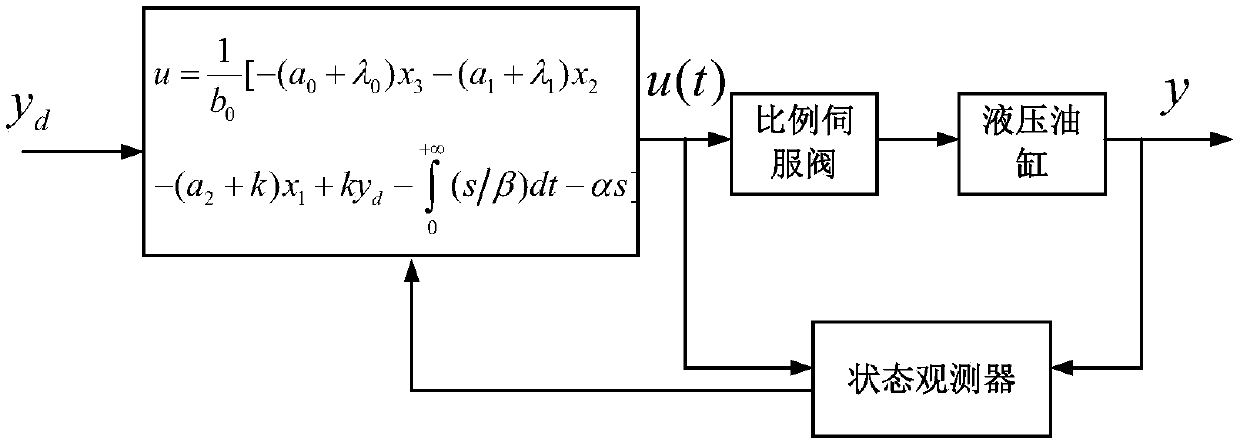

[0090] The invention drives the asynchronous motor to drive the quantitative pump to rotate and output high-pressure oil with a certain flow rate; through the filter, the reversing valve and the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com