Fault diagnosis method for rolling bearings based on enhanced modulation bispectral analysis

A rolling bearing and fault diagnosis technology, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve the problems of high-order spectrum interference of signals, fault feature extraction and analysis of adverse effects, etc., to achieve the effect of superior performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a rolling bearing fault diagnosis method based on enhanced modulation bispectral analysis:

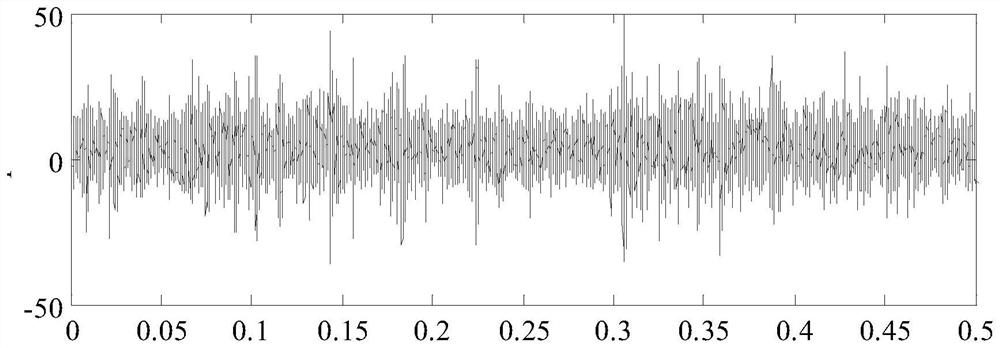

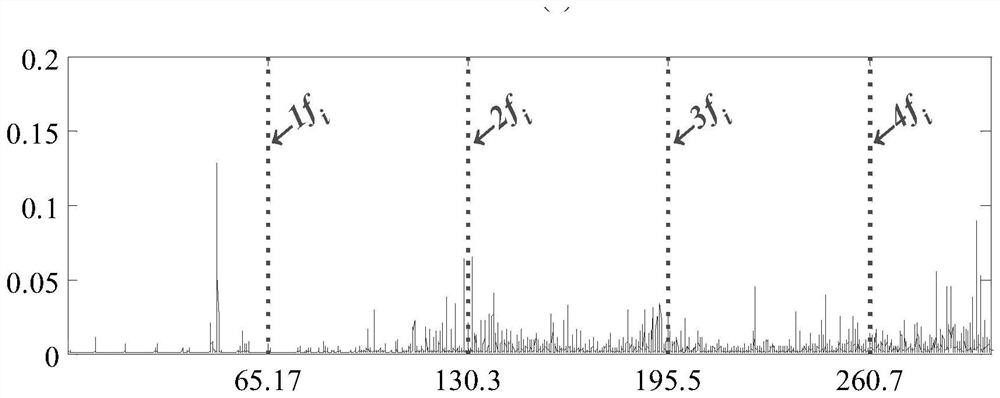

[0041] Step 1: Measure the vibration signal of the inner ring of the rolling bearing through the vibration sensor. The sampling frequency of the vibration signal is 96kHz, the sampling length is 2880000 points, and the fault frequency of the outer ring of the bearing is 65.17Hz. The waveform diagram and frequency domain diagram of the vibration signal are as follows: figure 1 , figure 2 As shown, it can be seen that there is a lot of noise and the component of the fault characteristic frequency cannot be extracted.

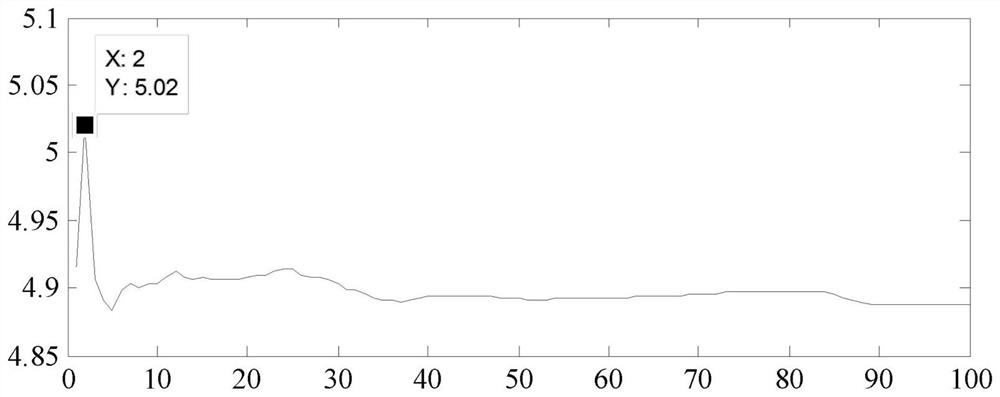

[0042] Step 2: Use the maximum kurtosis principle to adaptively determine the optimal order of the AR model, such as image 3 As shown; by selecting the order of the best AR model, the AR model is used to reduce the noise of the vibration signal, and the noise-reduced vibration signal is obtained;

[0043] Step 3: Separating the modulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com