Device and method for homogenizing loading force of defective rock samples by using fluid cushion

A loading force and defect technology, applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of small loading stroke of flexible bladder, deviation of pressure uniformity, uneven force bearing surface, etc. , to achieve the effect of optimizing the uniform load, reducing the restraint force and uniform stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Such as Figure 1-5 As shown, a device for using a fluid cushion to homogenize the loading force of a defective rock sample includes a cushion layer 2 laid on the loading surface of the defective rock sample test block 1, and the loading surface of the defective rock sample test block 1 is an uneven loading surface , the outer surface of the cushion layer 2 and the convex-concave defect of the loading surface of the defective rock sample test block 1 are completely fitted, the cushion layer 2 is provided with a vibrating plate 6, and the above-mentioned defective rock sample test block 1, the cushion layer 2 and the vibrating plate 6 are formed The whole is placed on the reaction force frame 8, and the vibrating plate 6 cooperates with the hydraulic jack 7.

[0040] In the cushion layer 2, the outer casing made of carbon fiber cloth is filled with adhesive fillers. The carbon fiber cloth is high-strength grade I, and the product model is I-200. The strength is ≥ 3400MPa...

Embodiment 2

[0051] A method for loading defective rock samples using the above-mentioned device, the method includes the following steps:

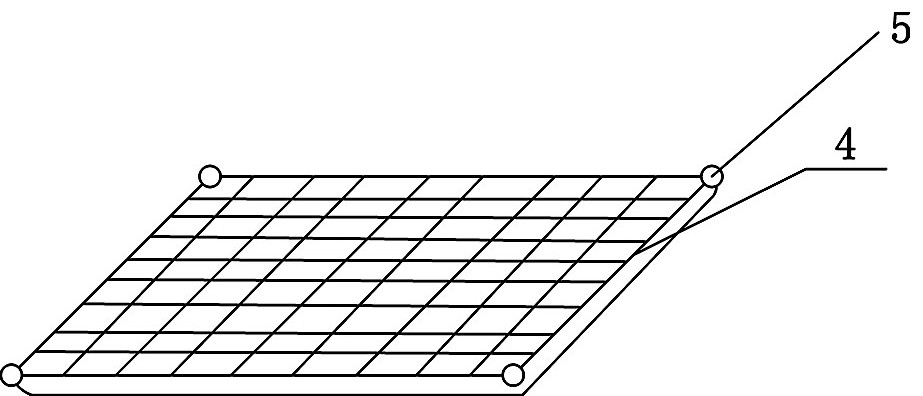

[0052] Step 1: Make the outer casing of the cushion layer 2: use carbon fiber cloth to sew the outer casing suitable for the size of the defective rock sample test block 1, and keep the opening of the filling material, and use iron wire to make it suitable for use with the cushion layer Protective net 4, the protective net 4 is placed on the surface of the outer layer casing and connected with the outer layer casing as a whole with connecting wires 5 at the four corners of the outer layer casing;

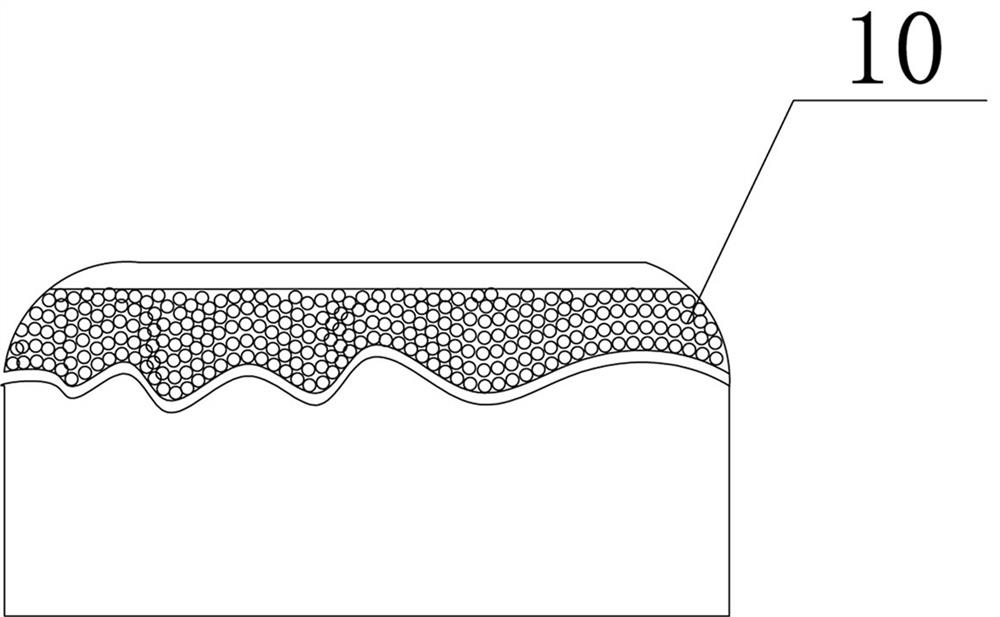

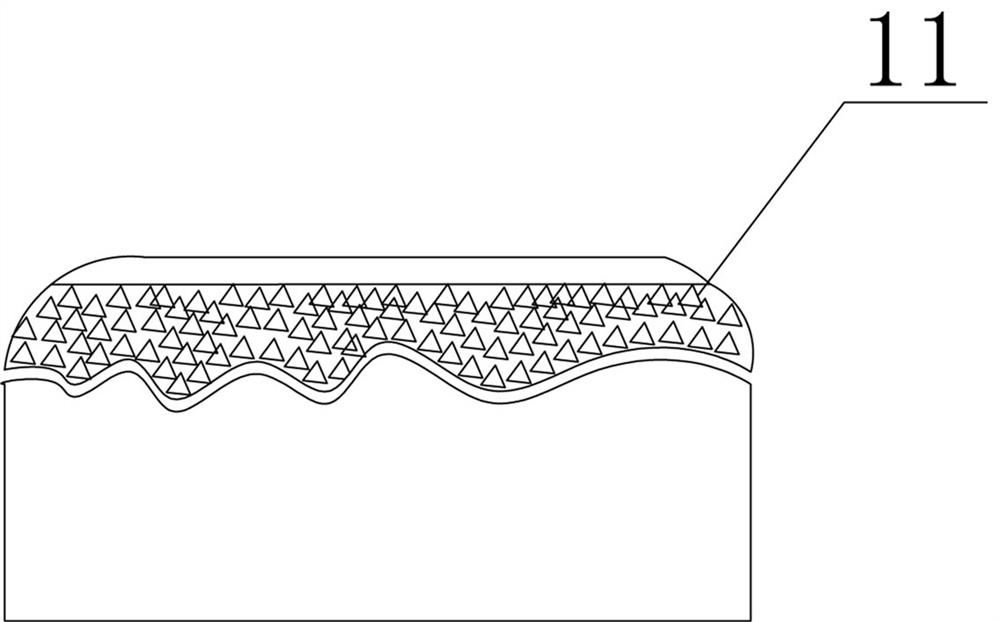

[0053] Step 2: Fill the filling material: fill the opening of the outer casing with metal balls 10 or gravel soil 11 of a certain grade to form a fitting filling, and open the opening of the filling material after filling Closed to make cushion 2;

[0054] Step 3: Prepare the reaction force frame 8, place the defective rock sample test block 1 on the react...

Embodiment 3

[0059] A method for loading defective rock samples using the above-mentioned device, when the method includes the following steps:

[0060] Step 1: Make the outer casing of the cushion layer 2: use carbon fiber cloth to sew the outer casing suitable for the size of the defective rock sample test block 1, and keep the opening of the filling material, and use iron wire to make it suitable for use with the cushion layer Protective net 4, the protective net 4 is placed on the surface of the outer layer casing and connected with the outer layer casing as a whole with connecting wires 5 at the four corners of the outer layer casing;

[0061] Step 2: Filling the filling material: fill the opening of the outer casing with fine sand 9 and water at a mass ratio of 1:3 into the outer casing to form a fitting filling, and leave a gap when the opening of the filling material is closed. A certain opening forms the water outlet 12, and a plug body and a closing bolt are installed in the outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com