Numerical control machine tool operating data collecting terminal having mobile communication capability and supporting data customization

A mobile communication and collection terminal technology, applied in the field of CNC machine tool operation data collection terminals, can solve the problems of data reliability and integrity reduction, and achieve the effects of ensuring stability, easy connection, and multiple data types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

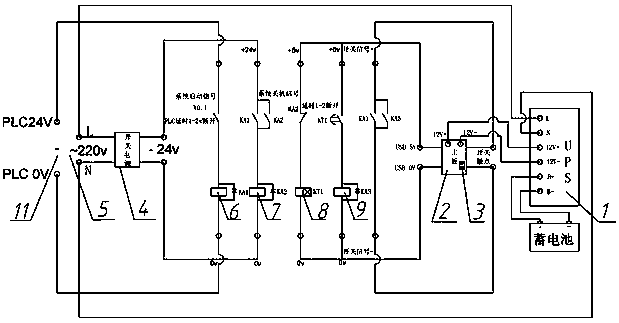

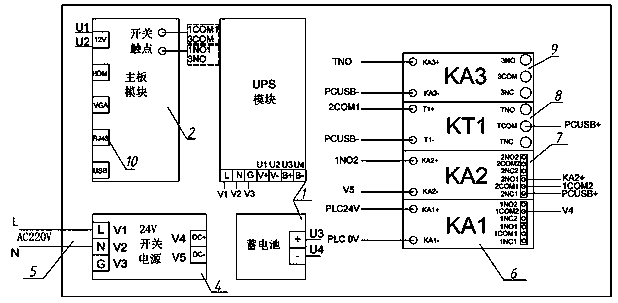

[0017] Embodiment one: see Figure 1~Figure 3 , a CNC machine tool operation data acquisition terminal with mobile communication capabilities and data customization support, including: UPS module (1), main board (2), 4G communication module (3), switching power supply (4), AC220V plug (5), 24V relay KA1 (6), 24V relay KA2 (7), 5V delay module KT1 (8), 5V relay KA3 (9) RJ45 interface (10) and PLC24V power supply signal interface terminal block (11), characterized in that: UPS module ( The input end of 1) is connected to the AC220V plug (5), the charging end of the UPS module (1) is connected to the battery; the input end of the main board (2) is connected to the output end of the UPS module (1). The UPS module (1) can continuously supply power to the main board (2); the input terminal of the 24V relay KA1 (6) is connected to the PLC24V power supply signal interface terminal block (11), and its normally open contact is connected to the switch contact of the main board (2); One ...

Embodiment 2

[0018]Embodiment 2: This embodiment is basically the same as Embodiment 1. The special features are as follows: the UPS module (1) has a 220V AC input terminal, a battery charging terminal, and a 12V-5A DC output terminal. 220V AC power supply, after conversion, 12V-5A DC power is supplied to the main board (2). If the machine tool cabinet is powered off, the battery in the UPS module (1) can continue to supply power to the main board (2) to complete a normal shutdown. The reliability and integrity of the data are guaranteed, and the service life of the equipment is extended. The 24V relay KA1 (6) has two sets of normally open and normally closed contacts, its rated voltage is DC 24V, powered by the PLC24V power supply signal interface terminal block (11), and one end of the PLC24V power supply signal interface terminal block (11) is connected to the required The PLC24V DC output terminal of the monitored machine tool is connected, and the other end is connected to the input t...

Embodiment 3

[0019] Embodiment three: the preferred embodiment of the present invention is described in detail as follows in conjunction with accompanying drawing:

[0020] The acquisition process of the CNC machine tool operation data acquisition terminal with mobile communication capabilities and data customization includes the following steps:

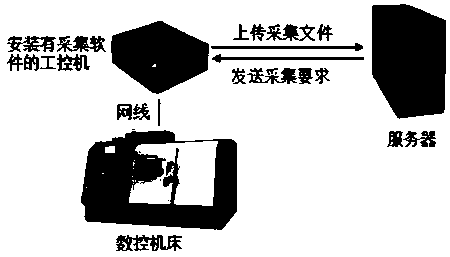

[0021] S1: Integrate the acquisition terminal described in the present invention with the electric cabinet of the CNC machine tool, the specific method is: connect the RJ45 interface (10) of the acquisition terminal to the machine tool through a network cable. Connect the AC220V plug (5) to the electric cabinet of the CNC machine tool to supply power to the acquisition terminal, and finally connect the PLC24V power supply signal line of the CNC machine tool to the PLC24 V power supply signal terminal block (11) of the acquisition terminal;

[0022] S2: The user creates a machine identification file in advance, and the identification file is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com