Patents

Literature

59results about How to "Rich data types" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

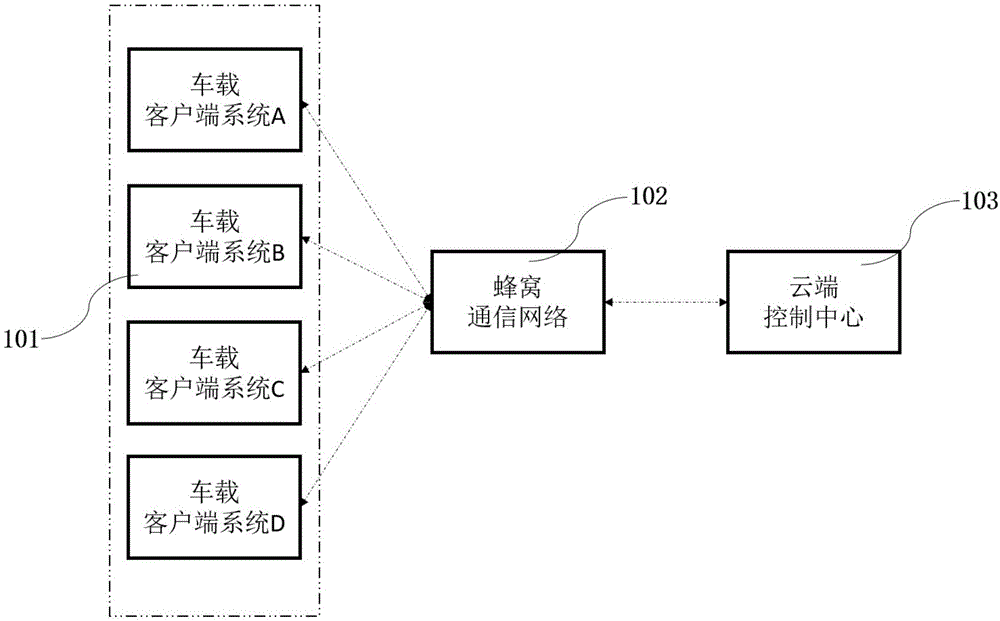

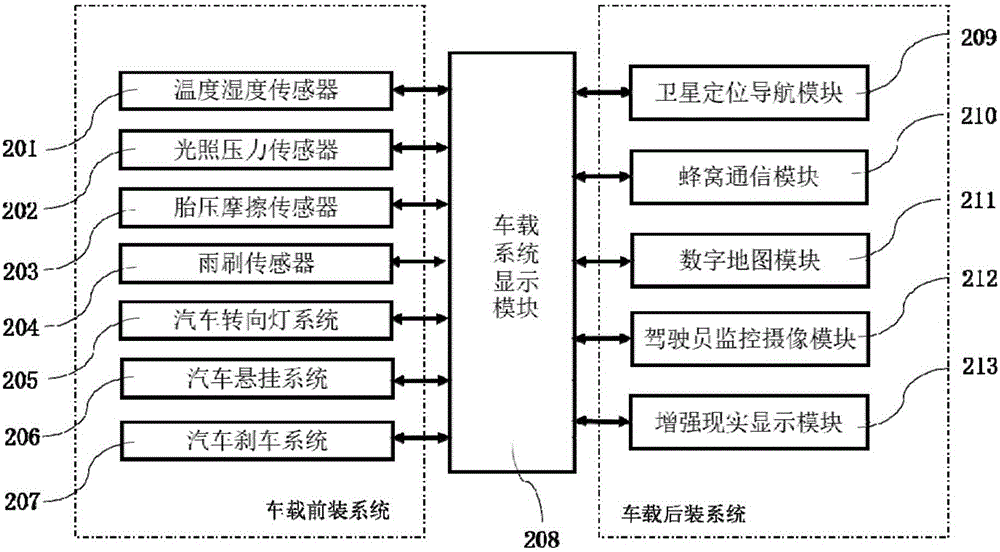

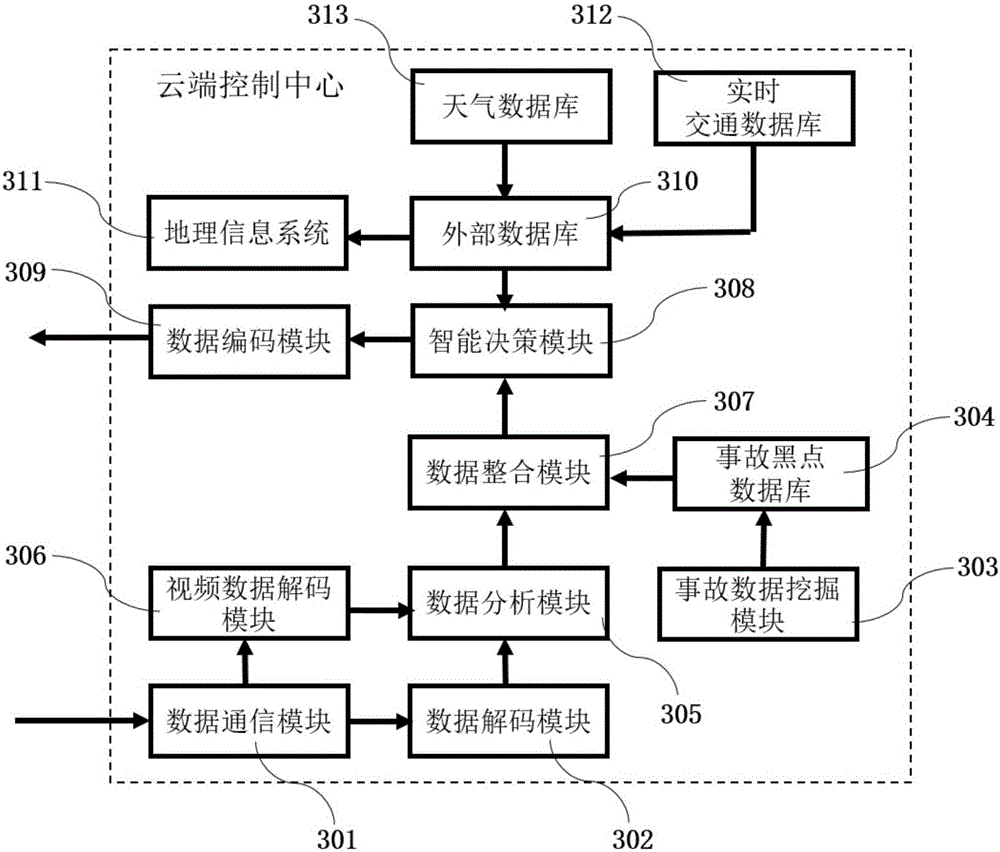

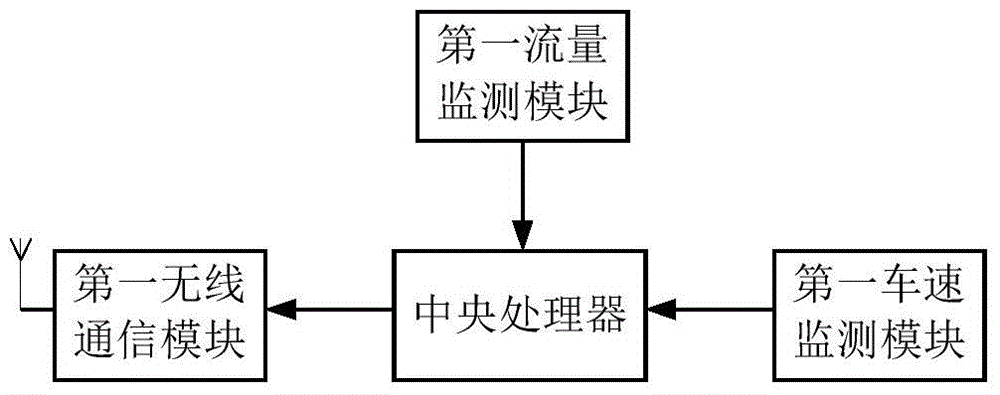

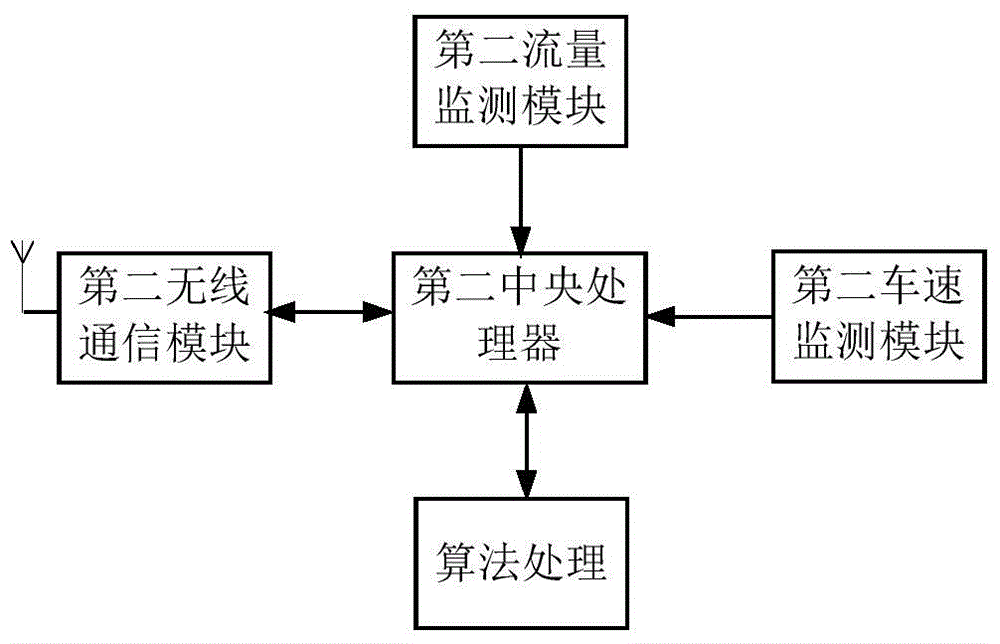

Car networking accident blackspot warning system and method based on augmented reality and cloud intelligent decision

InactiveCN106846863AImprove reliabilityRich data typesAnti-collision systemsDriver/operatorIn vehicle

The invention discloses a car networking accident black spot warning system and method based on an augmented reality and a cloud intelligent decision. The method comprises the steps that car operating data is collected through a vehicle-mounted client system layer, and the collected car operating data is sent to a cloud control center layer through a cellular communication network layer; a data decision package sent back from the cloud control center layer is received and displayed to a driver in an augmented reality mode combined with real road conditions; based on car operating data received in real time and data in a black spot database, the cloud control center layer makes decision analysis according to a car operating state and current traffic and weather conditions and publishes corresponding warning information to the vehicle-mounted client system layer in a data package format. By fusing various dynamic traffic data sources and combining the cloud intelligent decision and the augmented reality, the perceptibility of the driver to various accident risks on a road black spot can be greatly improved, the safety awareness of the driver on a invisible road black spot is enhanced, accordingly the accident rate is reduced, and the road black spot safety is improved.

Owner:叶昊

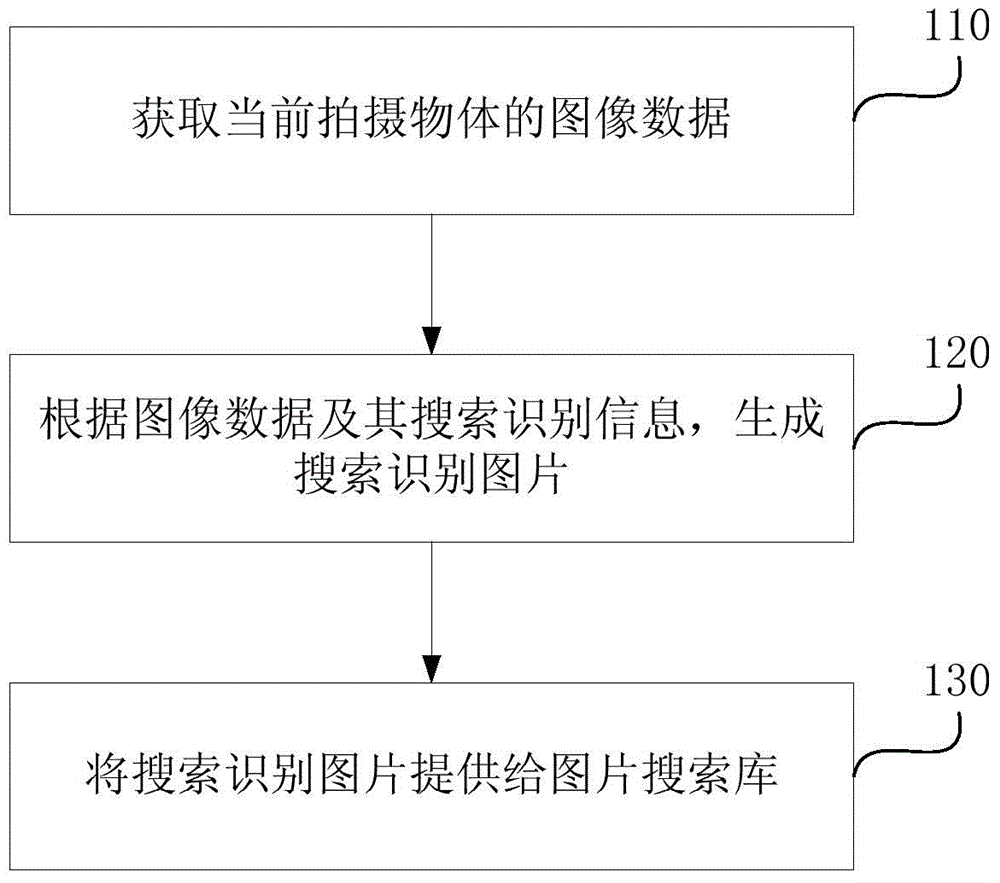

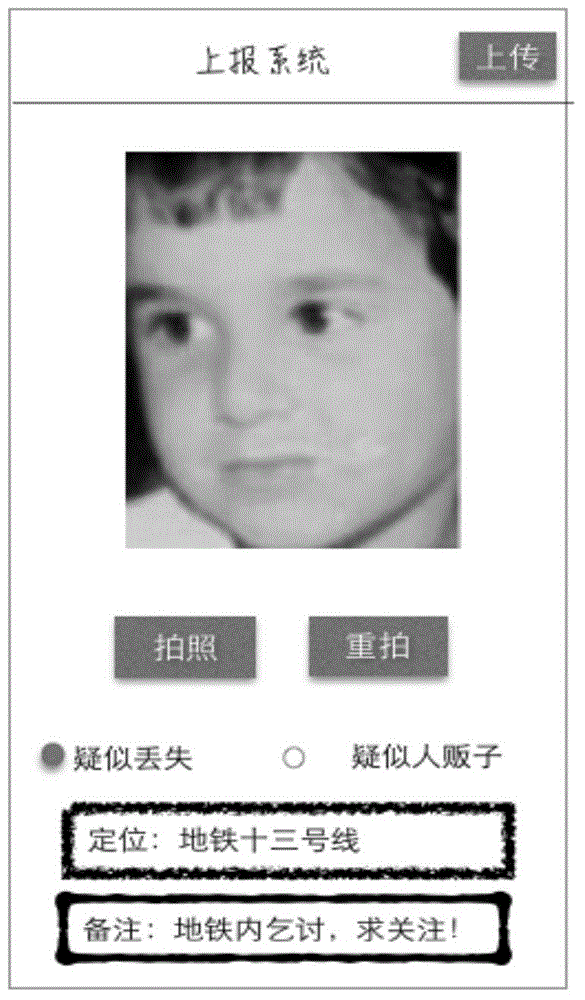

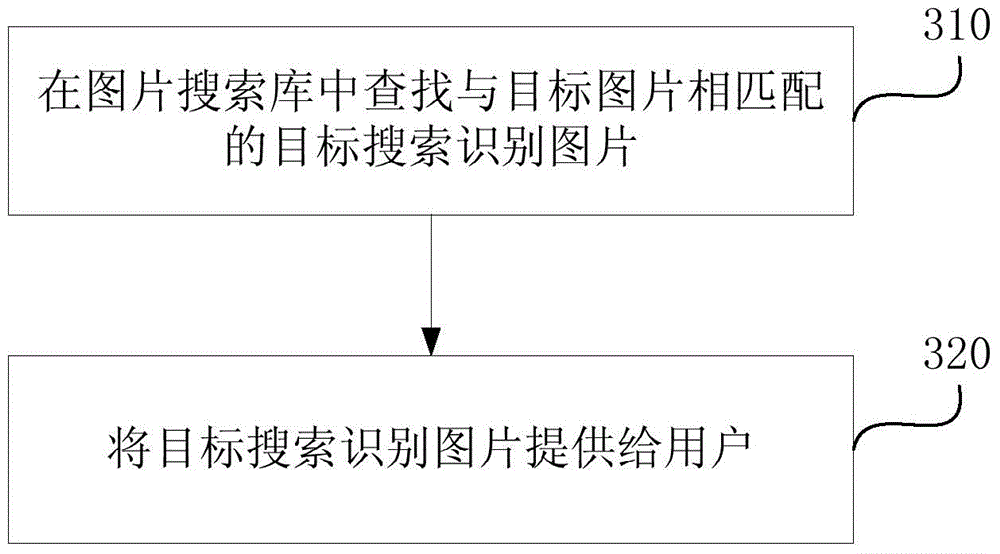

Method and device for generating picture search library and method and device for searching for picture

ActiveCN104133899AOptimized search technologyRich Data SourcesCharacter and pattern recognitionStill image data indexingImage retrievalData type

The embodiment of the invention discloses a method and device for generating a picture search library and a method and device for searching for a picture. The method for generating the picture search library comprises the steps that image data of a currently shot object are obtained; a search recognition picture is generated according to the image data and the search recognition information of the image data; the search recognition picture is provided for the picture search library; the search recognition information comprises the shooting time and shooting spot of the image data. The method for searching for the picture comprises the steps that a target search recognition picture matched with a target picture is searched for in the picture search library; the target search recognition picture is provided for a user, and the target search recognition picture comprises the image data and the search recognition information; the search recognition information comprises the shooting time and shooting spot of the image data. An existing picture search technology is optimized, data sources and data types in the picture search library are enriched, and the growing individualized and convenient picture search needs of people are met.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

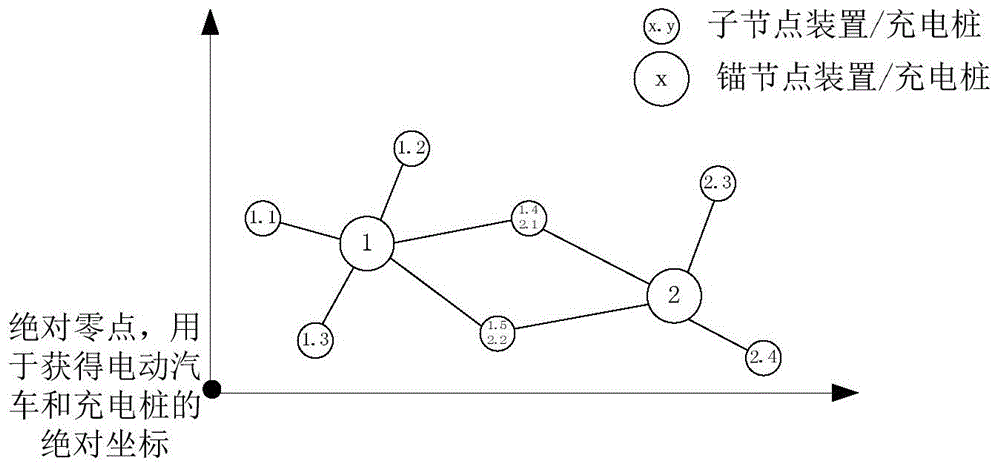

Charging scheduling system based on electric vehicle charging priority and method thereof

InactiveCN104933466ARich data typesReasonable solutionReservationsForecastingEngineeringElectric vehicle

The invention discloses a charging scheduling system based on an electric vehicle charging priority and a method thereof. The system comprises a child node apparatus and an anchor node device. The sub-node apparatus is installed on a child node charging pile and is used for collecting charging pile data. The anchor node device is installed on an anchor node charging pile and is used for data integration and processing, executing a charging scheduling algorithm, processing user feedback information and carrying out charging scheduling. According to a position of an anchor node, area division is performed. One anchor node manages several child nodes. Data collection and operation efficiency are increased. By using the charging scheduling algorithm, according to information of an electric vehicle and the charging pile, charging priority degree assessments are performed twice; global comparison is performed on a final priority degree assessment value; relative priorities of the electric vehicle on each reachable charging pile are determined so that global solution is realized. By using the system and the method in the invention, a utilization rate of a charging pile resource and charging efficiency of the electric vehicle are increased; and charging system performance of the electric vehicle is improved.

Owner:WUHAN UNIV +1

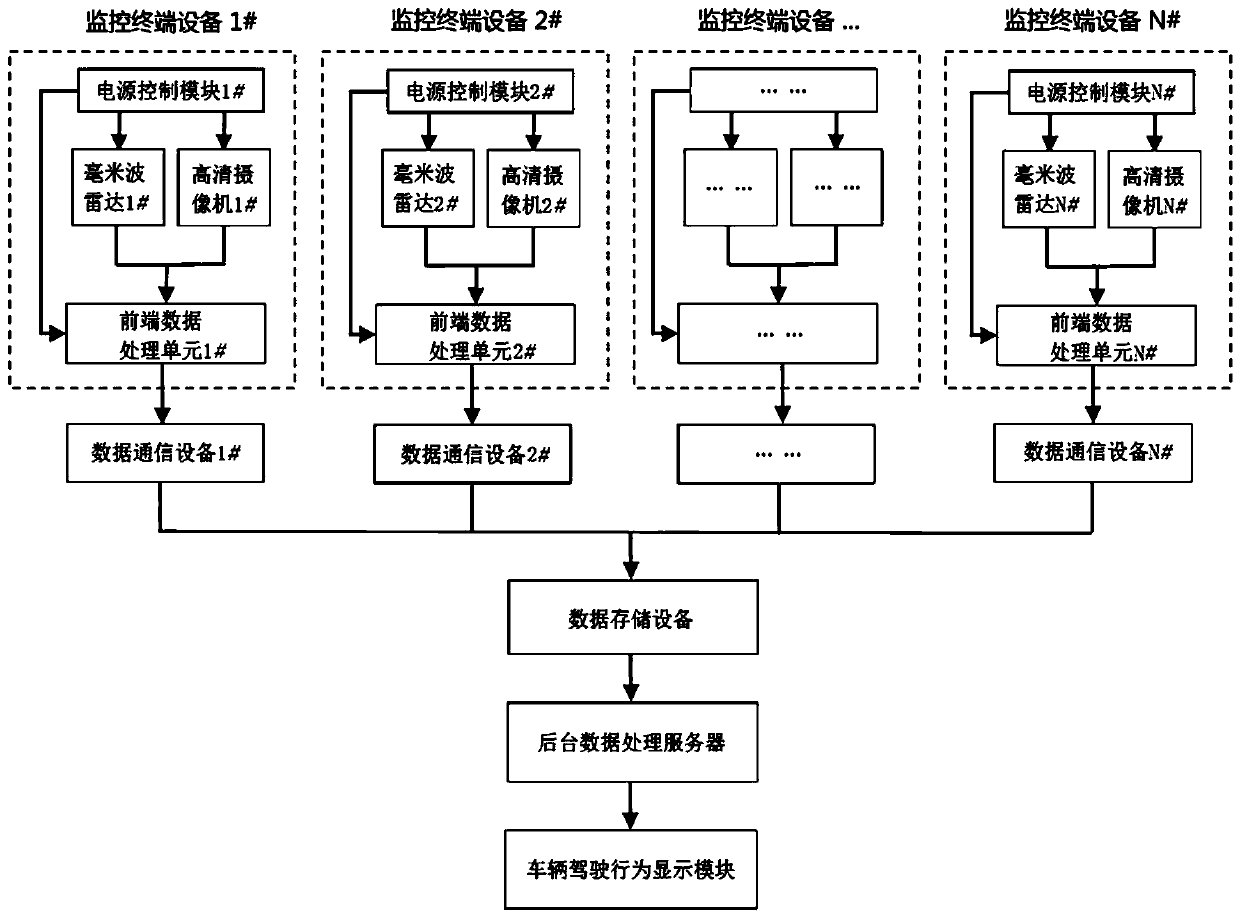

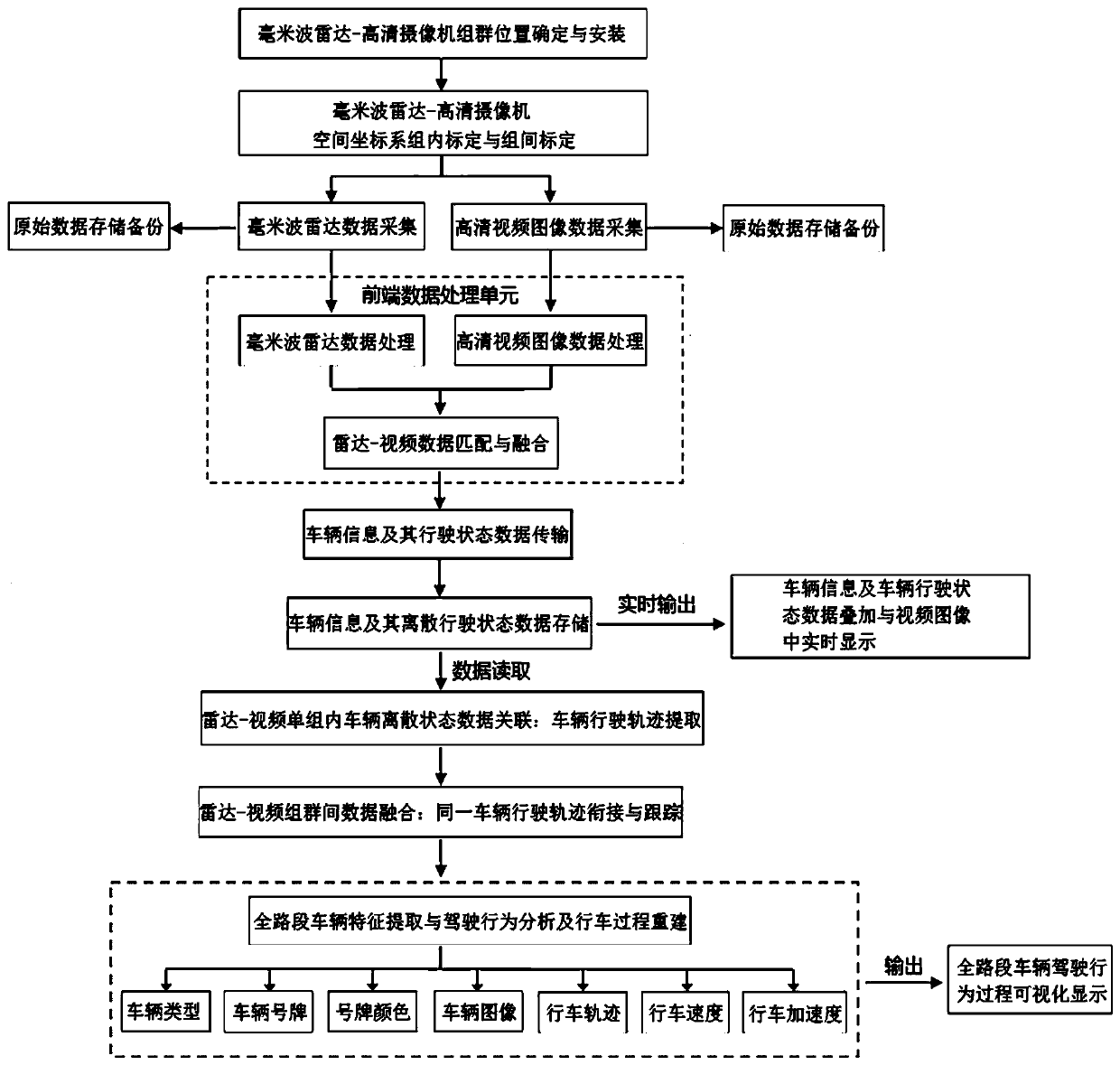

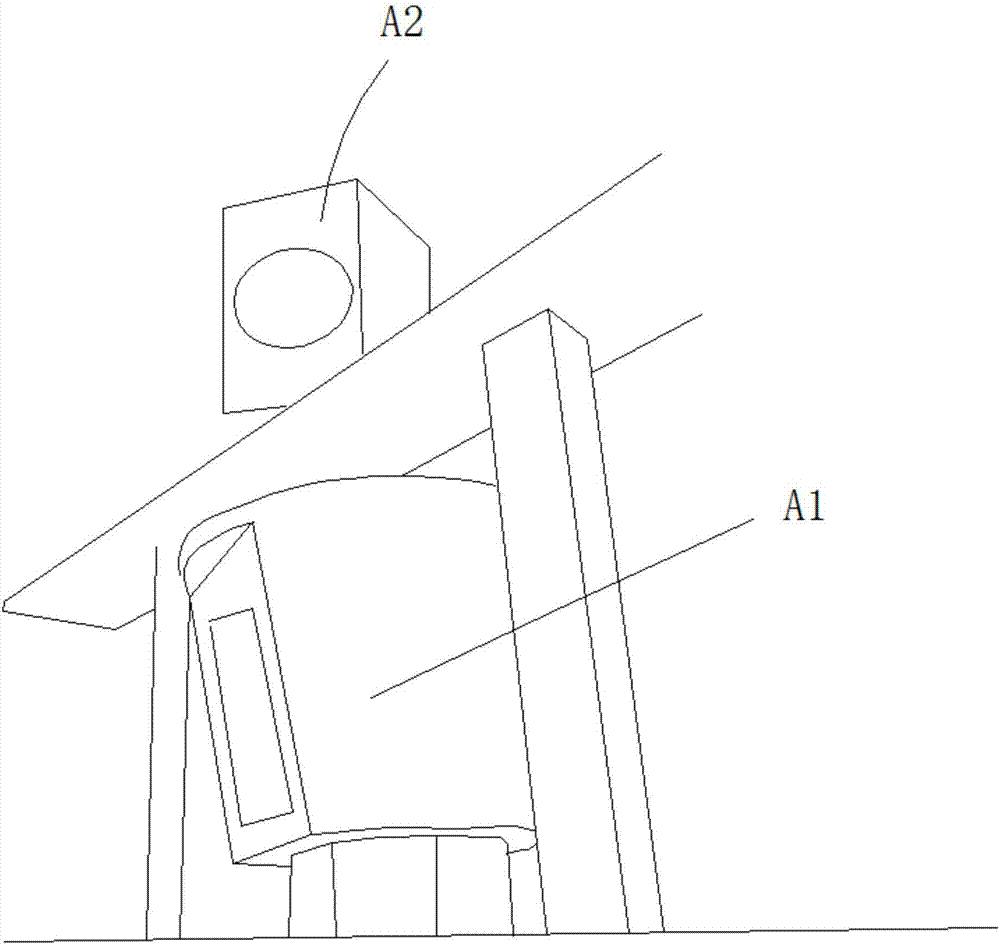

Vehicle behavior monitoring system based on radar and video group, and realization method thereof

ActiveCN110738846AOvercome accuracyOvercoming reliabilityDetection of traffic movementTelevision systemsData acquisitionEngineering

The invention relates to a vehicle behavior monitoring system based on radar and video group, and a realization method thereof. The system comprises multiple sets of monitoring terminal equipment, multiple sets of data communication equipment, data storage equipment, a background data processing server, a vehicle driving state display module and the like; the monitoring terminal equipment is composed of a millimeter wave radar, a high-definition camera, a front-end data processing unit module and a power control module. Compared with the prior art, the system disclosed by the invention realizes the advantage complementation of the millimeter wave radar data and the high-definition video image data on traffic data acquisition by deeply fusing the millimeter wave radar data and the high-definition video image data, so that the detected data type is more comprehensive, and the accuracy, reliability and robustness are further improved by steps, thereby being beneficial to providing technical support for the aspects of traffic control, safety early warning and the like.

Owner:TONGJI UNIV

3D laser and 2D imaging synchronized scanning device and scanning method thereof

The invention discloses a 3D laser and 2D imaging synchronous scanning device and a scanning method thereof. A laser receiving and sending matrix is installed on a 3D laser radar, the point laser receiving and sending matrix and a line scanning imaging sensor are installed on the same rotatable platform in parallel, the height of the point laser receiving and sending matrix and the line scanning imaging sensor is the same, the positions are close or connected, the rotatable platform can drive the point laser receiving and sending matrix and the line scanning imaging sensor to synchronously rotate, the synchronous scanning device further comprises a control device, the control device comprises a synchronous clock module, the synchronous clock module is connected to the 3D laser radar and the line scanning imaging sensor signal, the control device can synchronously send the signal to the 3D laser radar and the line scanning imaging sensor through a synchronous clock module, so that the 3D laser radar and the line scanning imaging sensor can synchronously scan, and therefore the obtained data has synchronism and facilitates the fusion of radar laser scanning data and line scanning image data.

Owner:江苏中天智控智能系统有限公司

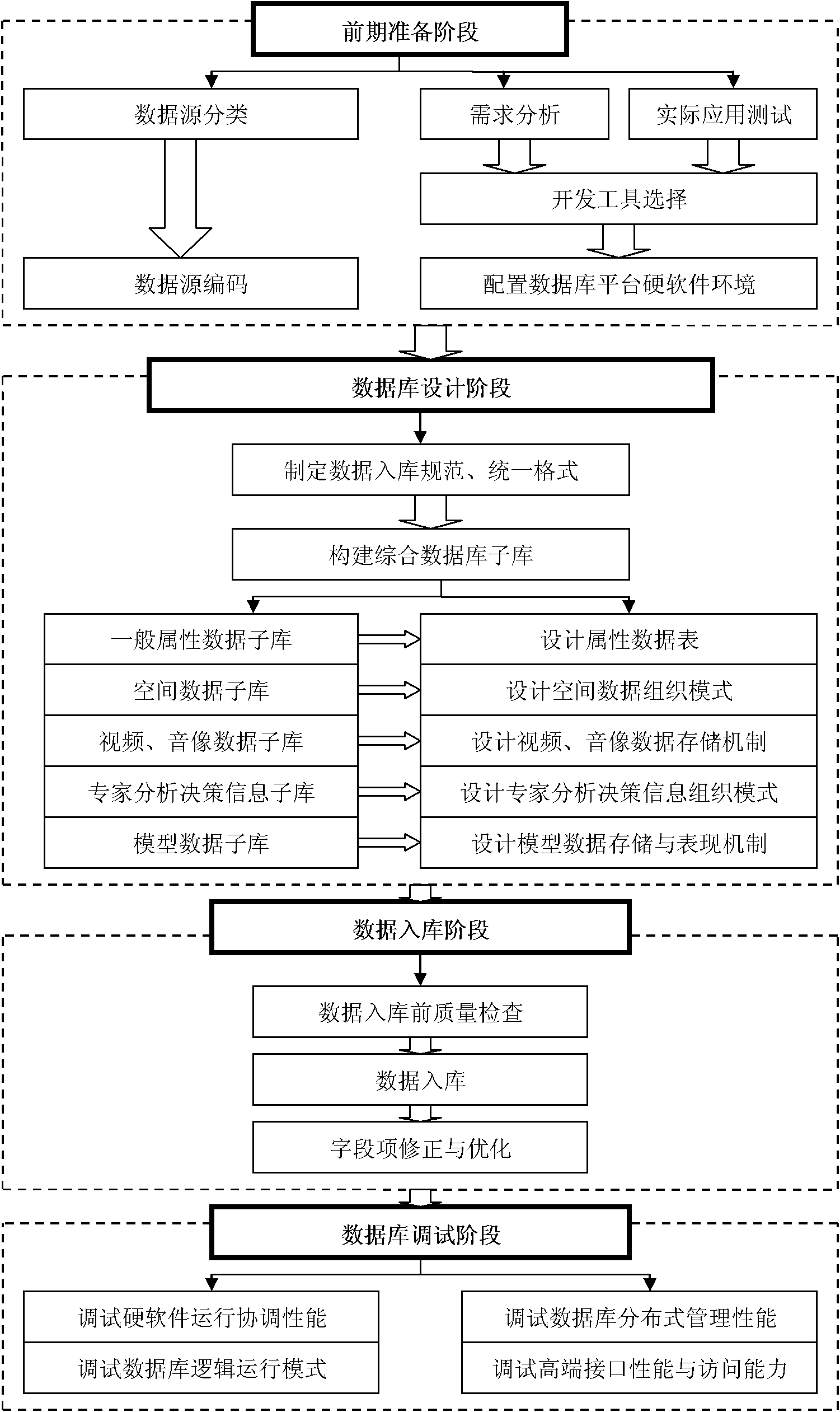

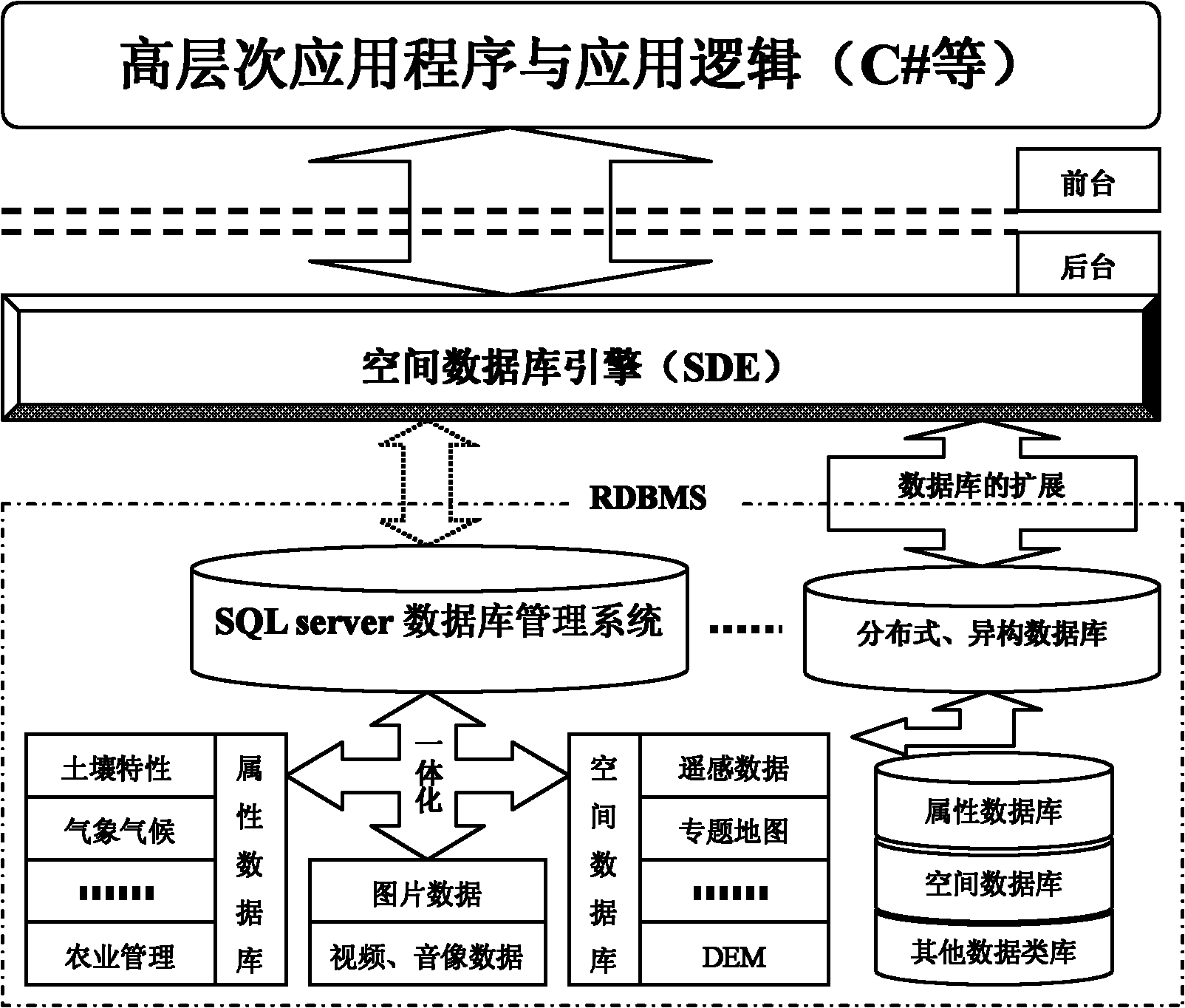

Method for establishing comprehensive agricultural environmental information database

InactiveCN101853305AImplement storageAchieve integrationData processing applicationsSpecial data processing applicationsDatasheetInformation support

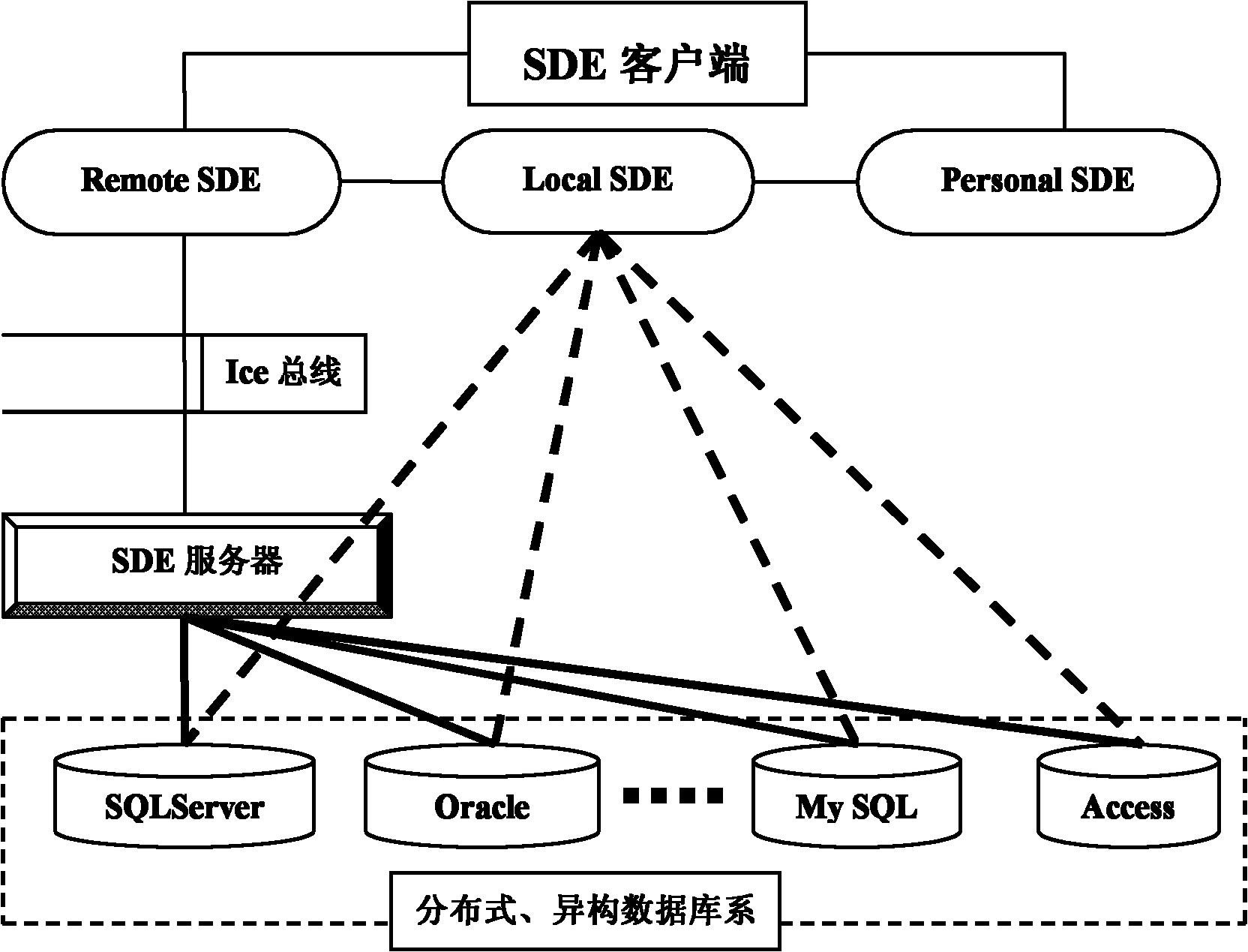

The invention discloses a method for establishing a comprehensive agricultural environmental information database. The comprehensive agricultural environmental information database comprises four sub-databases, i.e. a general attribute sub-database, a space sub-database, a video and audio sub-database and a model sub-database. The general attribute sub-database stores and manages agricultural environmental information attribute data through arranging a two-dimensional datasheet in a relation database management system SQL server. The establishment method of the space sub-database comprises that effective storage of space data in a relation database is realized through a space database engine and management logic is created through SDE in a classifying and layering way. The invention has the advantages of the practicability is high, the pertinence is high, the universality is good and powerful information support is provided for the comprehensive integration application of agricultural information.

Owner:HUNAN UNIV

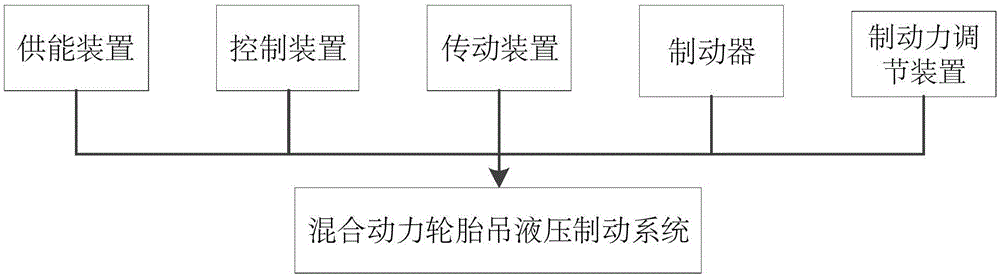

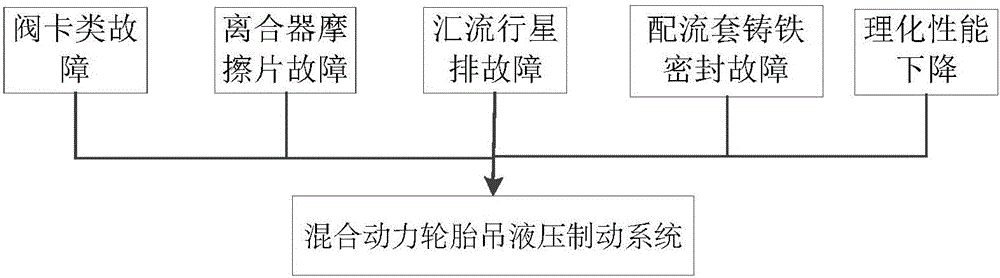

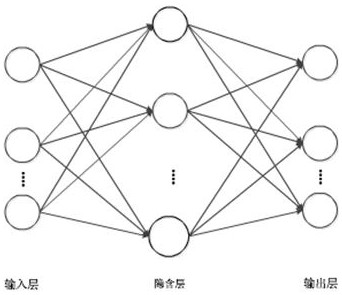

Hydraulic brake system multi-source fusion fault indicating method based on GA-BP network

ActiveCN106482938AAchieve integrationAvoid the defect of easy to fall into local optimumMachine part testingNeural learning methodsAnalysis dataGenetic algorithm

The invention discloses a hydraulic brake system multi-source fusion fault indicating method based on a GA-BP network. The method comprises steps of: sampling oil liquid in a hydraulic brake system, randomly dividing samples into a training set and a test set, analyzing the samples and carrying out multi-source information fusion to obtain analysis data related to the oil liquid; using the genetic algorithm to optimizing an initial value of a neural network; using analysis data of the training set for modeling of the GA-BP network; testing the neural network obtained through training by use of the test set until performance of the neural network can meet requirements; and finally, using the trained GA-BP neural network to analyze states of the hydraulic brake system and indicating possible faults. According to the invention, the states of the monitored hydraulic brake system can be qualitatively and quantitatively evaluated; the fault diagnosis process is quite intelligent; and detection accuracy is quite high.

Owner:WENZHOU UNIVERSITY

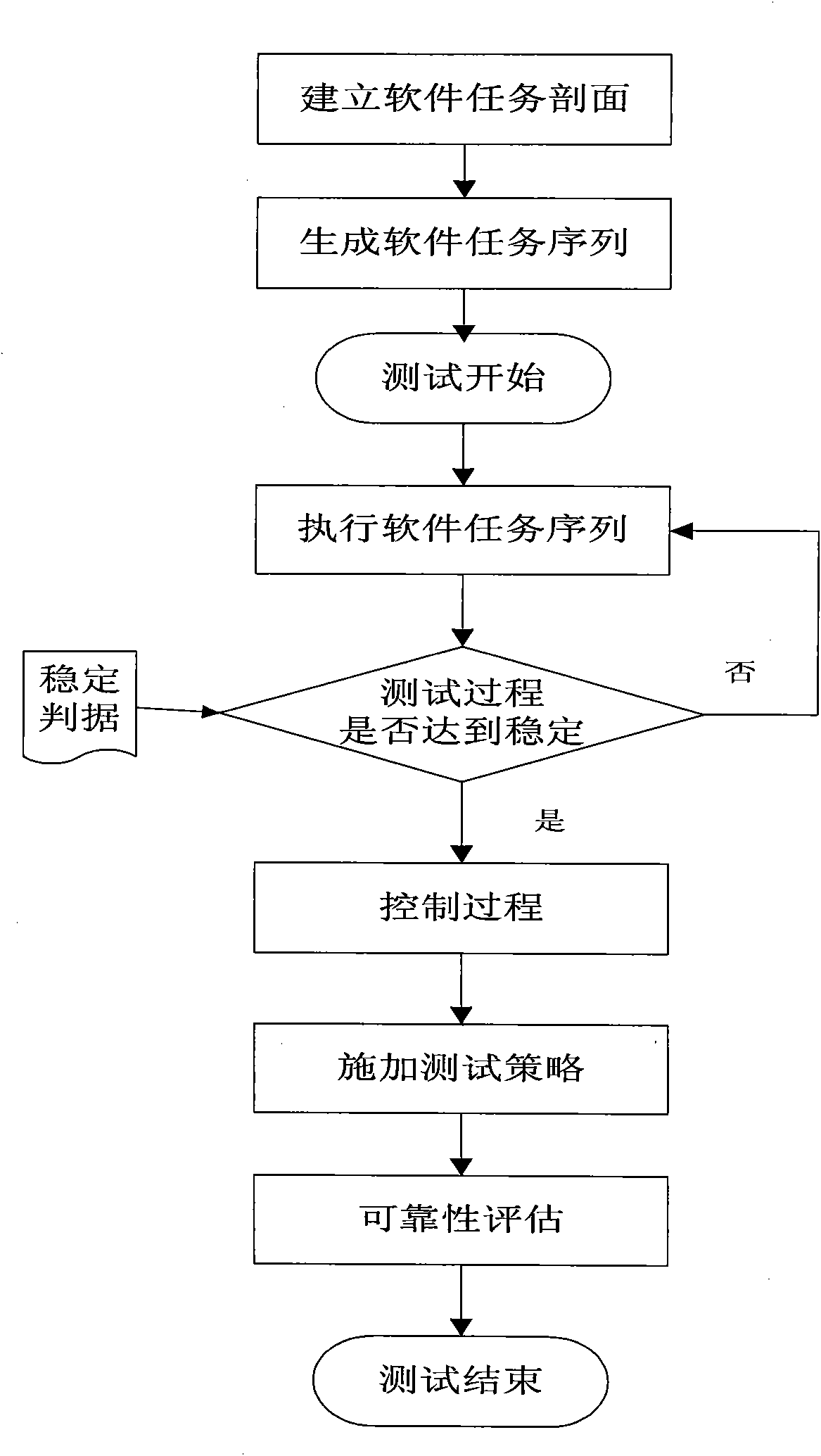

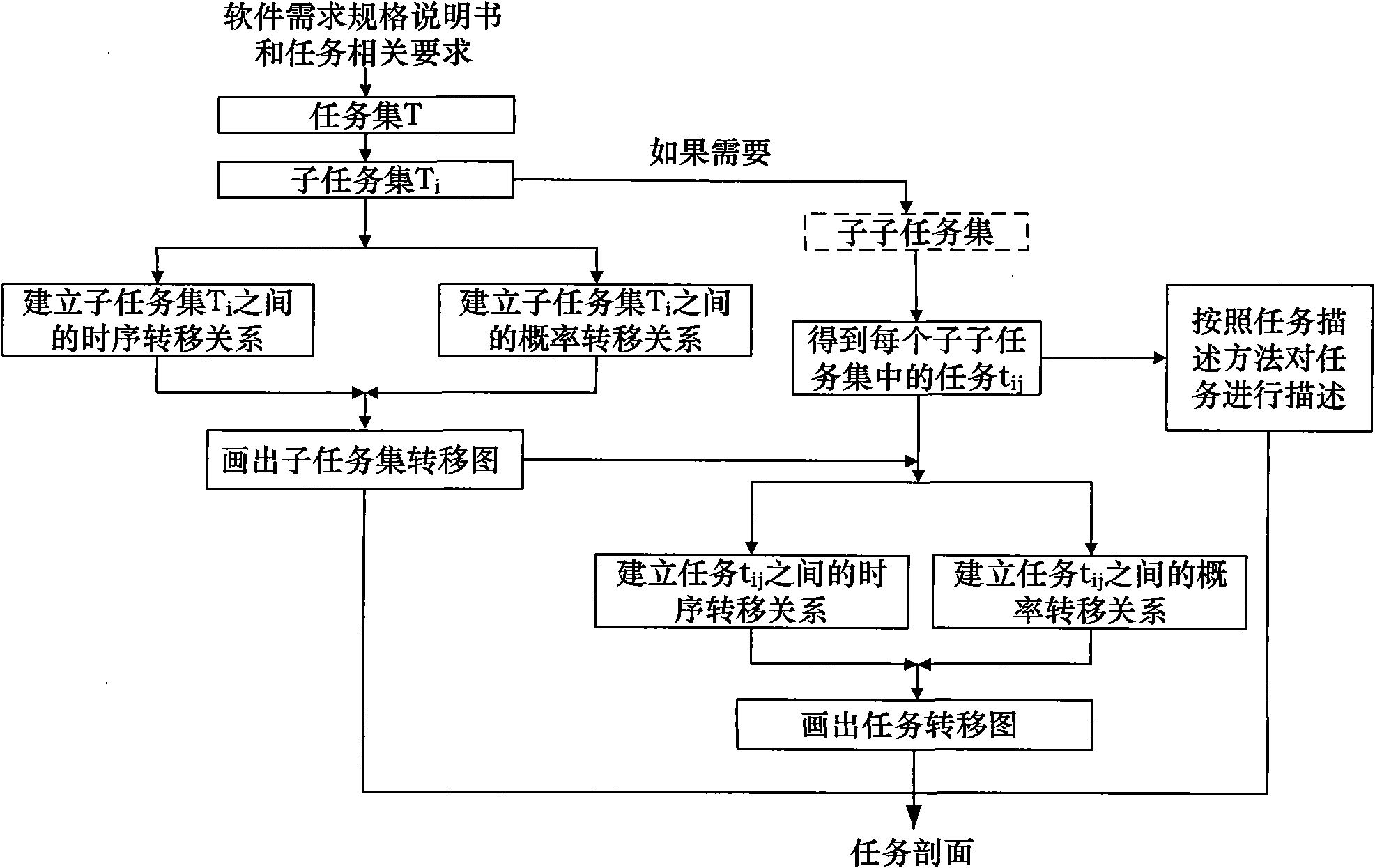

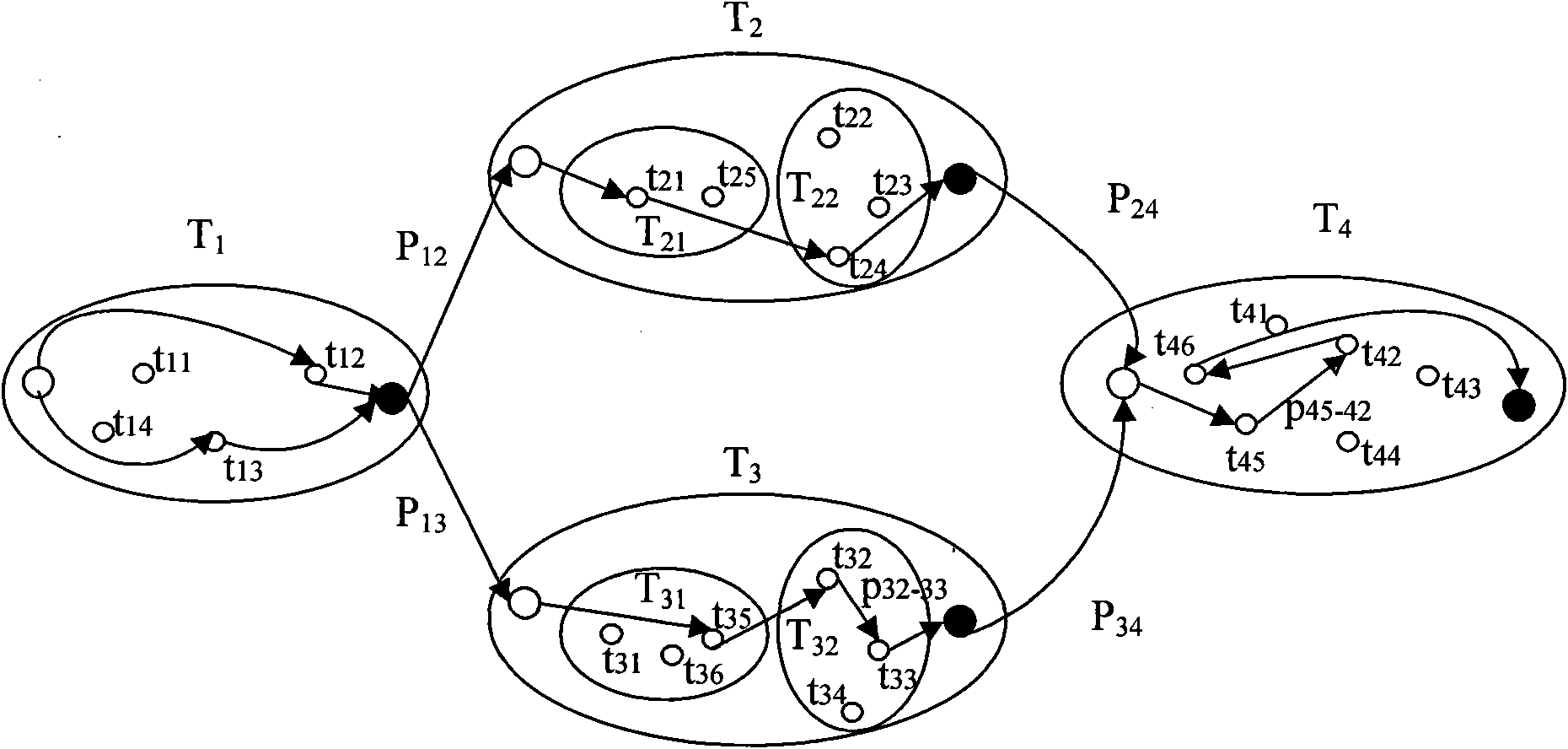

Embedded software reliability accelerated test method

InactiveCN101894068AComprehensive reliability testImprove test efficiencySoftware testing/debuggingTest inputEmbedded software

The invention discloses an embedded software reliability accelerated test method, which comprises the following steps of: by establishing a software task profile, randomly extracting and generating a software task sequence as applied complete and valid test input in actual reliability test; and in the test process, counting and collecting task characteristics and task statuses, entering a controlprocess after the test process is stable, applying a test strategy and finally performing engineering assessment on software reliability. In the method, the test strategy in the control process fulfills the aim of rationally, highly efficiently and acceleratedly testing the reliability, and expands the concept in the embedded software reliability test; the software task sequence generated based on the software task profile can satisfy the description and coverage of complex input conditions and ensures the credibility of reliability test data; and the assessment method is independent of the superposed mathematical distribution of failure data, and is applied to the reliability assessment, without overhigh requirement on accuracy, on embedded software.

Owner:BEIHANG UNIV

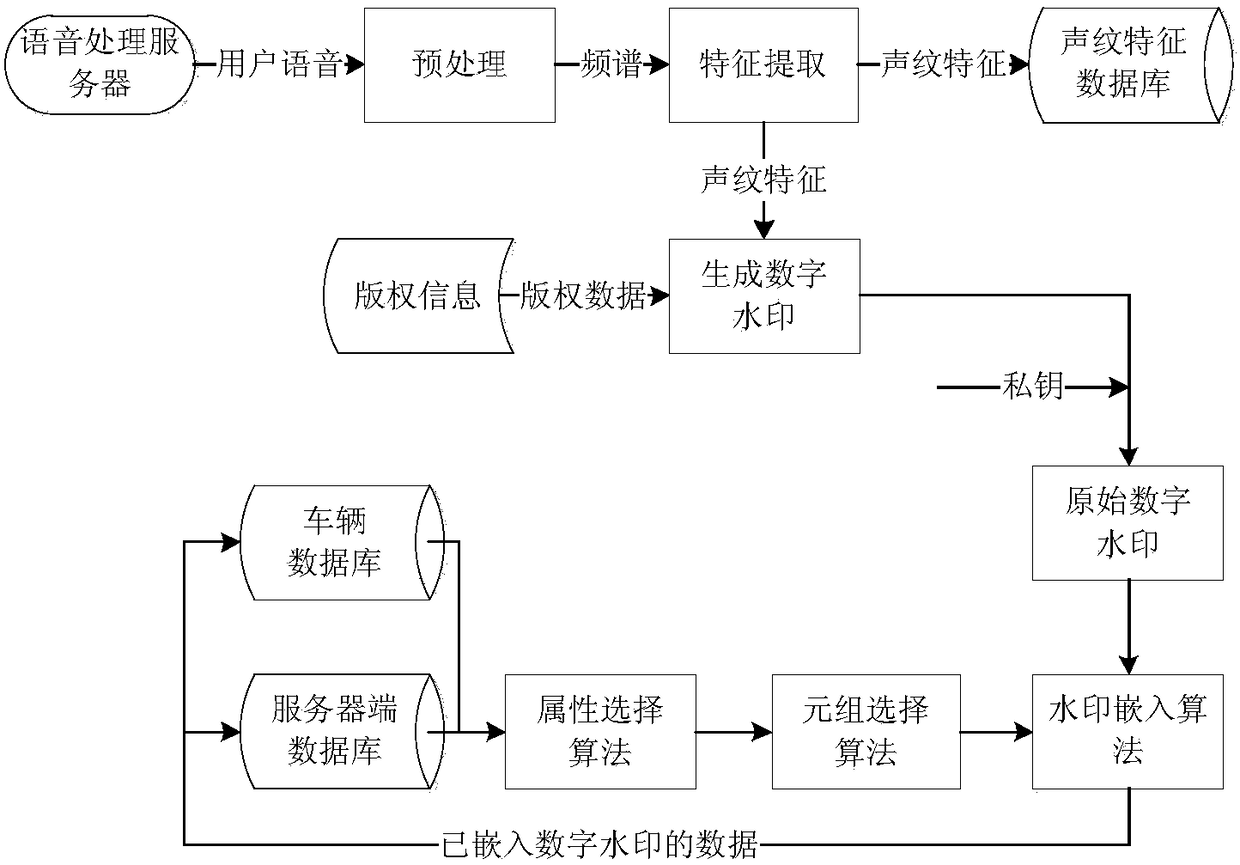

Digital watermark embedding and protection methods for database

ActiveCN108614961AImprove robustnessIncrease imperceptibilityProgram/content distribution protectionThe InternetBinary tree

The invention discloses a digital watermark embedding method for a database. The method comprises the steps of scoring an attribute column of the target database, and according to a scoring result, selecting an attribute of performing embedding; by using a tuple selection algorithm and a binary tree-based histogram shifting algorithm, marking a tuple embedded with a digital watermark, and storingthe position of a mark through a mapping matrix; and according to the mapping matrix, embedding the digital watermark in the target database for multiple times repeatedly by using a watermarking algorithm of the binary tree-based histogram shifting algorithm. The invention furthermore discloses a protection method for the database and a watermark generation and embedding method for the internet car database. Compared with other methods, the method has the advantages that the robustness and imperceptibility of the digital watermark are improved through the algorithm; the attack resistance capability is stronger; the quantity of information which can be used for authentication is higher; and the effect of the digital watermark during specific application is enhanced.

Owner:DONGFENG PEUGEOT CITROEN AUTOMOBILE

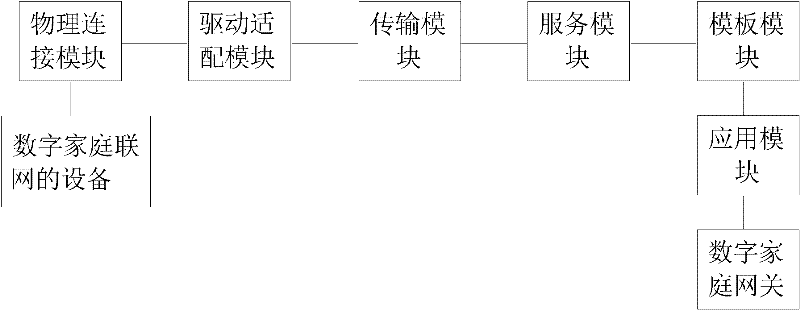

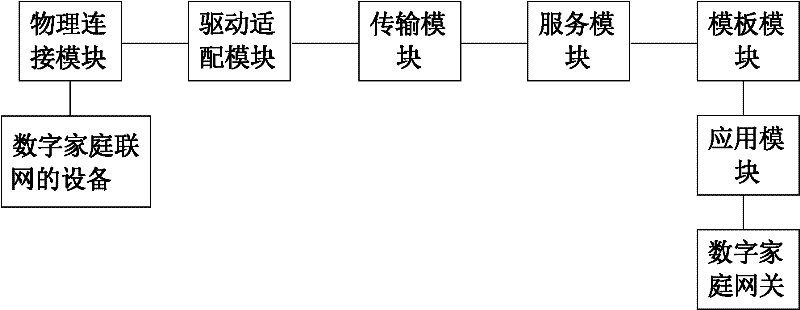

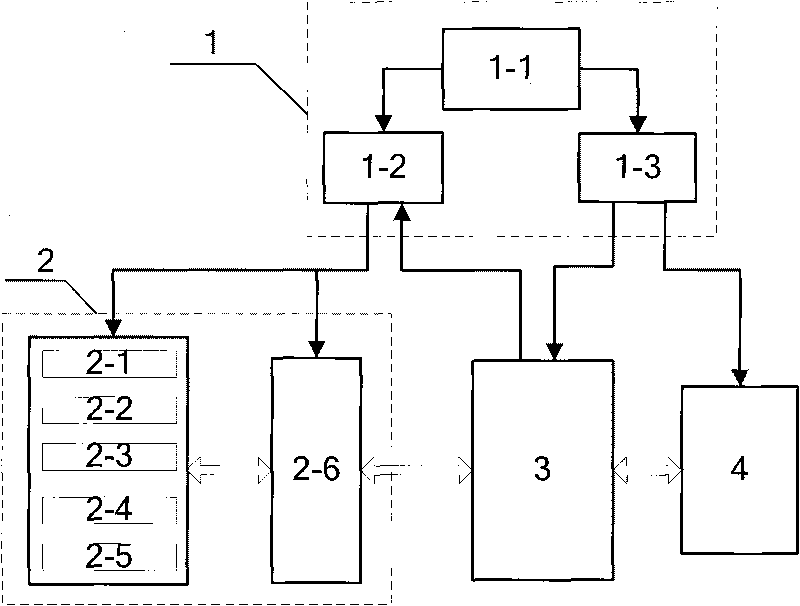

Middleware system for digital home

The invention relates to a control system for a digital home, in particular to a middleware system for the data and information management of the digital home. The middleware system for the digital home comprises a physical connection module, a drive adaptation module, a transmission module, a service module, a template module and an application module, wherein the physical connection module is connected with the transmission module through the drive adaptation module; the transmission module is connected with the template module through the service module; and the template module is connected with the application module. By the middleware system for the digital home, information service and device function service are seamlessly combined in the digital home, so that problems about the standardization and fusion of home devices and the information service are solved in a service level.

Owner:QINGDAO PENGHAI SOFT CO LTD

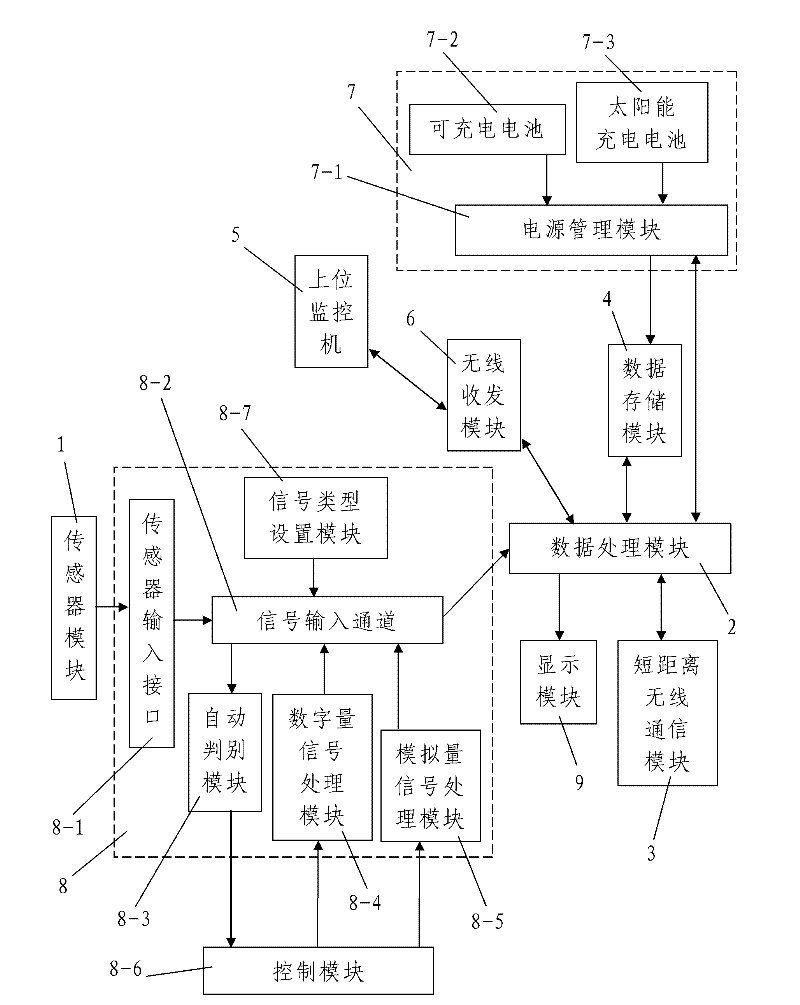

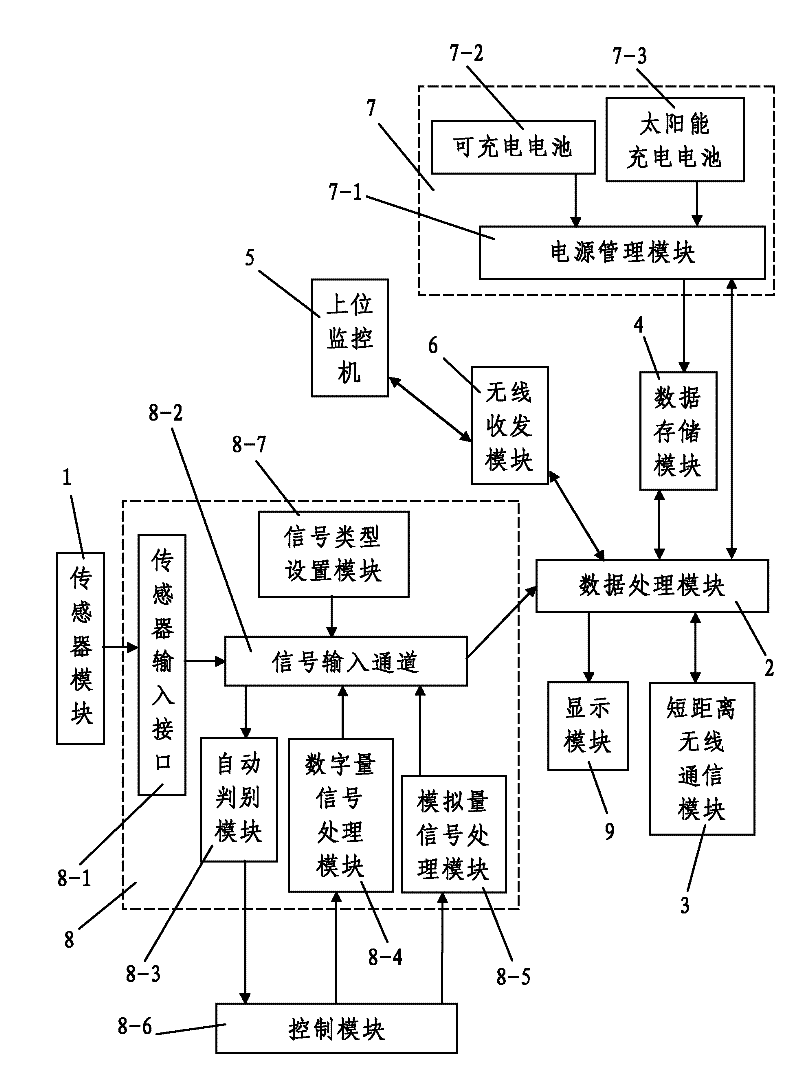

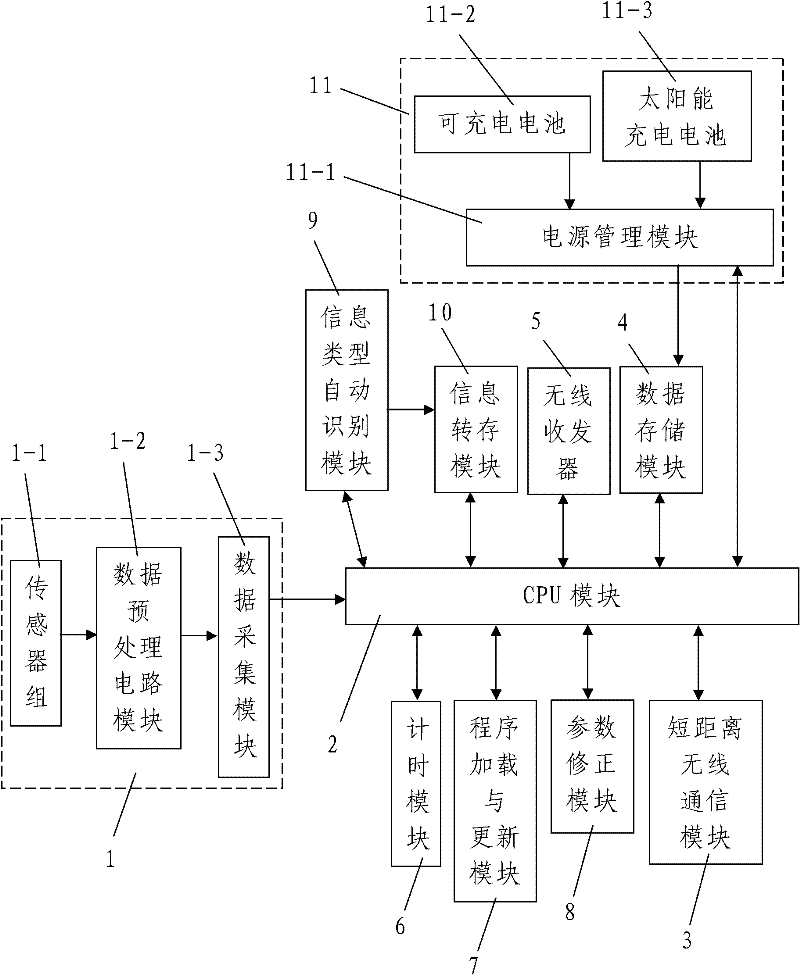

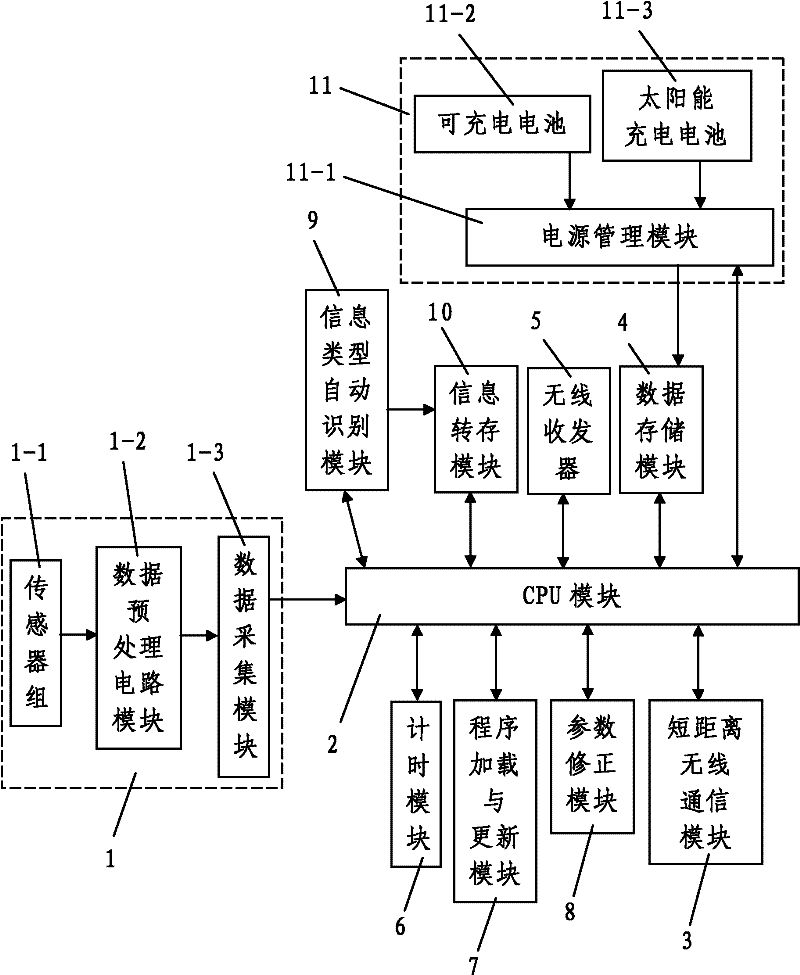

Wireless sensing network node capable of realizing simultaneous access of digital quantity and analog quantity

InactiveCN102548032ALarge spreadHigh propagation speedNetwork topologiesNetwork deploymentMultiple sensor

The invention discloses a wireless sensing network node capable of realizing simultaneous access of digital quantity and analog quantity. The node comprises a sensor module, a data processing module, a short-range wireless communication module, a wireless transceiving module and a power supply module. The sensor module is a sensor group composed of a plurality of sensors, the sensor group communicates with the data processing module via a digital quantity and analog quantity multiplex interface, and the digital quantity and analog quantity multiplex interface comprises a sensor input interface, a signal input channel, an automatic distinguishing module for automatically distinguishing the type of the signal input by the signal input channel, a control module, and a digital signal processing module and an analog signal processing module controlled by the control module according to the distinguishing result of the automatic distinguishing module. The invention has reasonable design, convenient network deployment and maintenance, simple operation, good use effects, and high intelligence degree, and can satisfy actual demands of synchronous processing of analog signals and digital signals and simultaneous accessing of multiple sensor signals of different types.

Owner:XIAN CENTN TECH

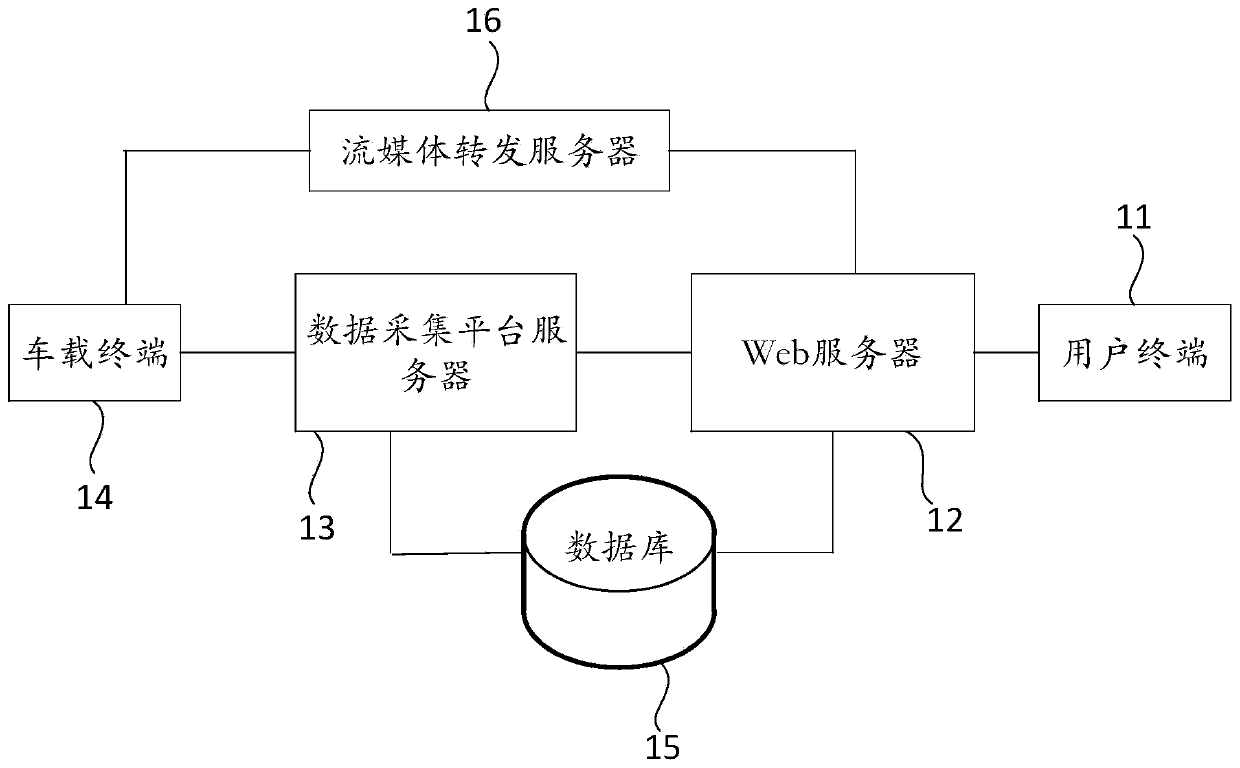

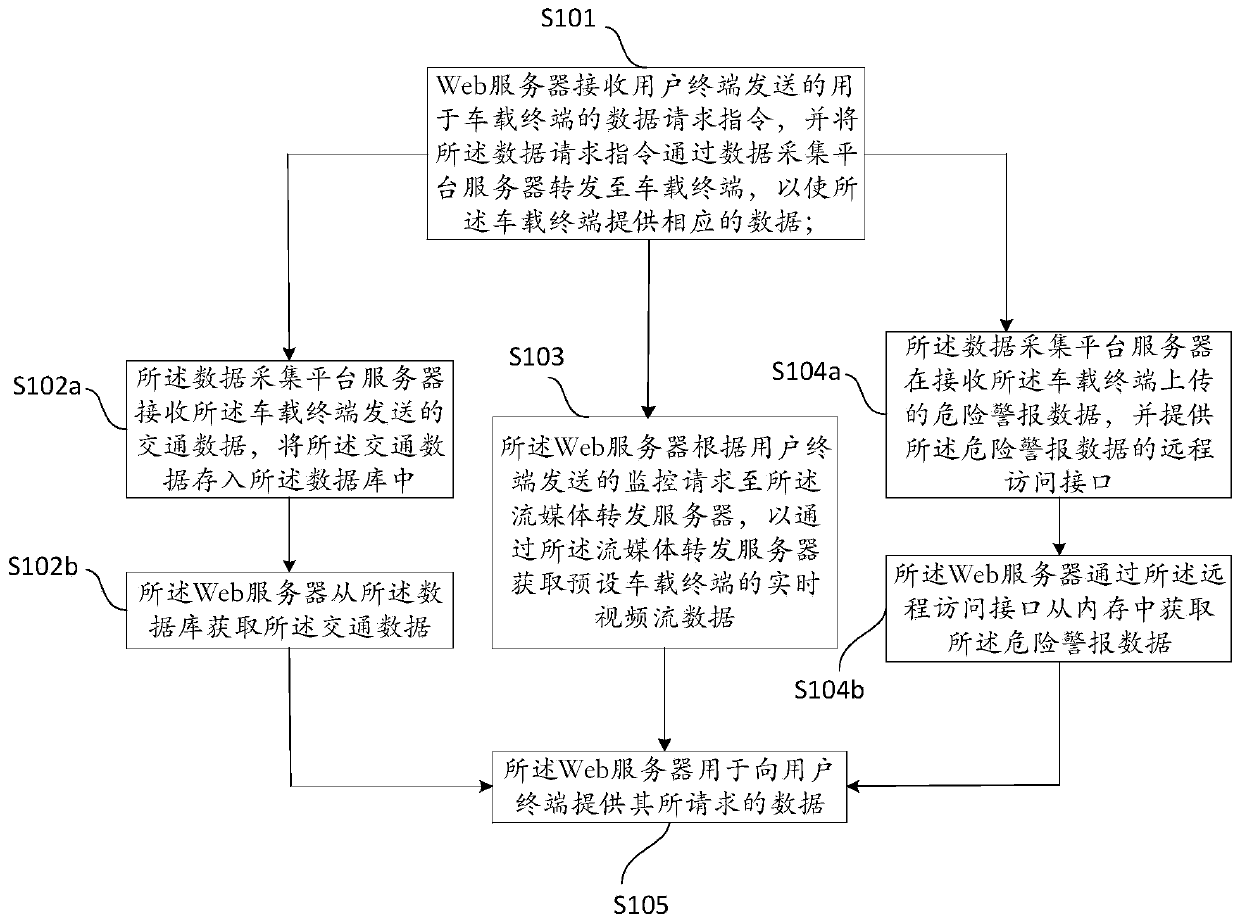

A vehicle-mounted terminal data transmission system and method

ActiveCN109729151AImprove data sharing efficiencyLarge capacity differenceRegistering/indicating working of vehiclesTransmissionWeb serviceStream data

The invention provides a vehicle-mounted terminal data transmission system and method. The vehicle-mounted terminal data transmission system comprises at least one vehicle-mounted terminal, a data acquisition platform server, a Web server, a database and a streaming media forwarding serve; the vehicle-mounted terminal is used for recording traffic data of a vehicle; The Web server can send a datarequest instruction to the vehicle-mounted terminal through the data acquisition platform server, so that the vehicle-mounted terminal sends required traffic data to the Web server through the data acquisition platform server; The data acquisition platform server provides a real-time memory access interface to push the traffic data or stores the traffic data in a database for the Web server to obtain; And the Web server can also obtain real-time video streaming data of the preset vehicle-mounted terminal from the streaming media forwarding server. According to the vehicle-mounted terminal datatransmission system provided by the invention, the efficiency of data sharing among the vehicle-mounted terminal, the data acquisition platform server and the Web server can be improved.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

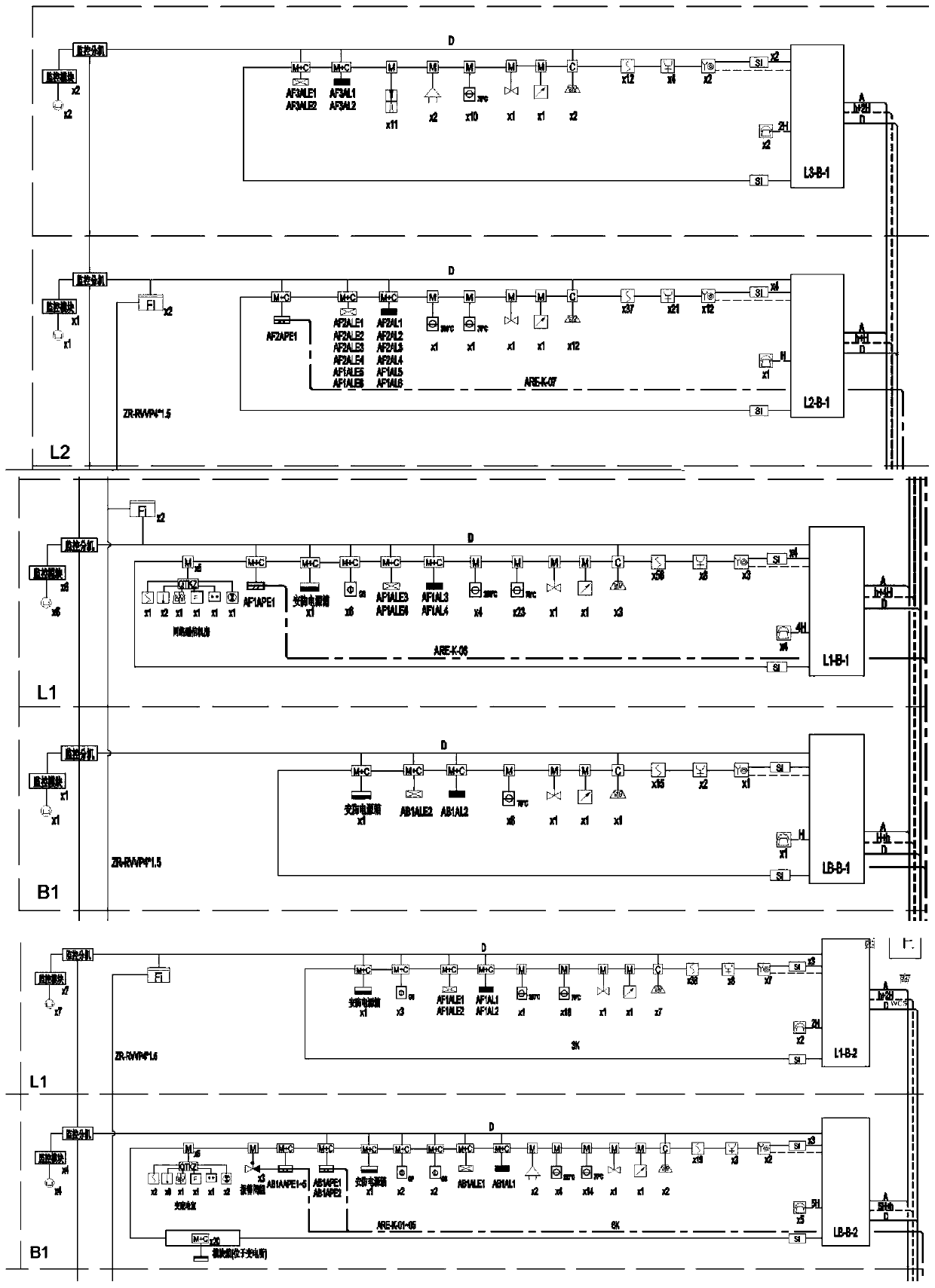

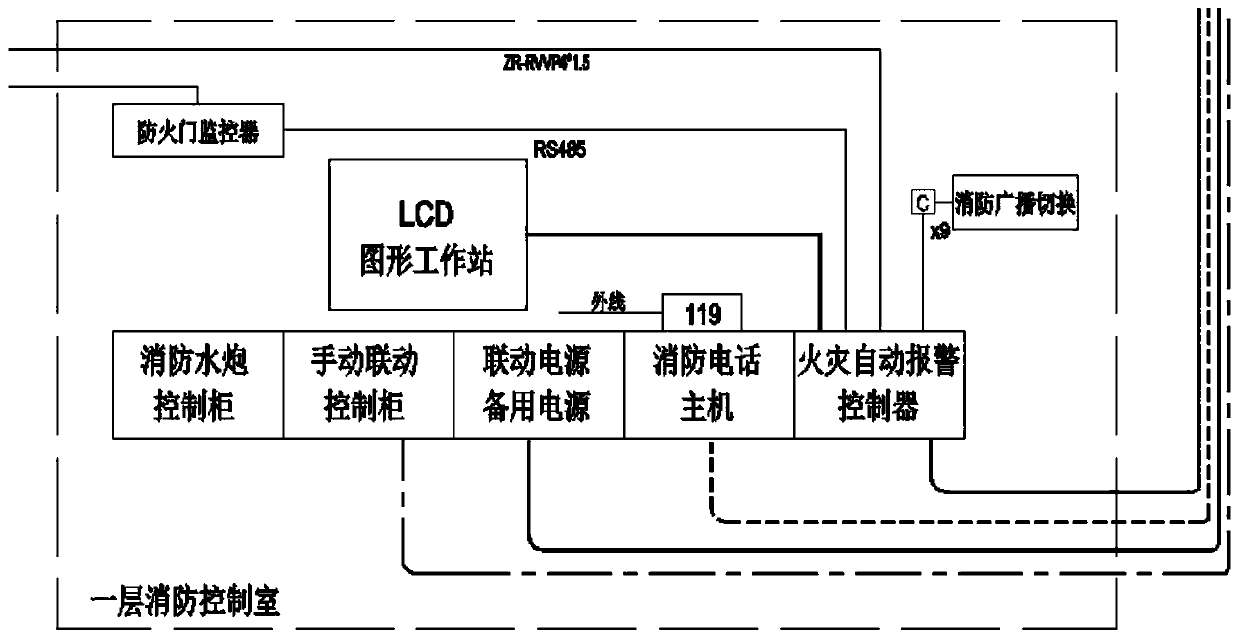

Automatic fire disaster alarm system based on big data

InactiveCN109893818AGuaranteed normal startupFast data flowMechanical apparatusFire rescueEngineeringWire breakage

The invention discloses an automatic fire disaster alarm system based on big data, and relates to a firefighting system in the construction and installation work. The automatic fire disaster alarm system comprises the steps that a remote PC end, a mobile phone and mobile patrolling terminal equipment are set, a firefighting control chamber is arranged, a two-bus loop is adopted in an automatic fire disaster alarm system and an automatic firefighting alarm system, system alarming is not influenced if wire breakage happens to any point, firefighting linkage control is achieved, in other words, afire disaster alarm system is in linkage with a control table, an automatic hard pull wire is used for linkage control over a fire hydrant pump, a spraying pump and a smoke preventing and dischargingdraught fan in a firefighting water pump room, and a firefighting monitoring chamber can monitor liquid level display signals of a firefighting water pond. The automatic fire disaster alarm system solves a series of unpredictable problems possibly existing during specific installing since parameters are single and reliability of an early warning system is probably not high; rapid data circulation, diverse data types and value density can be achieved, starting of the fire disaster alarm system is greatly guaranteed, and obvious benefits are brought to engineering construction.

Owner:CHINA MCC17 GRP

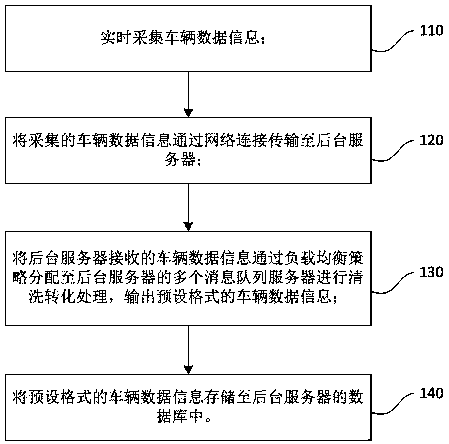

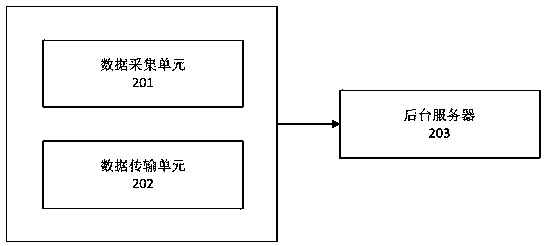

Vehicle data management method and vehicle data management system

InactiveCN108337309AGuaranteed normal transmissionRich data typesRegistering/indicating working of vehiclesParticular environment based servicesData managementData Applied

The invention discloses a vehicle data management method and a vehicle data management system, and the method comprises the following steps: acquiring vehicle data information in real time; transmitting the acquired vehicle data information to a background server through a network connection; allocating the vehicle data information received by the background server to a plurality of message queueservers of the background server through a load balancing strategy to perform cleaning and conversion, and outputting the vehicle data information of a preset format; storing the vehicle data information of the preset format to a database of the background server, wherein the vehicle data information comprises vehicle localization position data, vehicle operating state data, vehicle driving posture data, real-time road environment video data during vehicle driving process, driver state image data and vehicle outside illumination intensity data. The method and the system provided by the invention guarantee enough data for following vehicle driving analysis through abundant data types; and by unified processing of the background server, data of various types are integrated into applicable data structures.

Owner:上海灏领科技集团有限公司

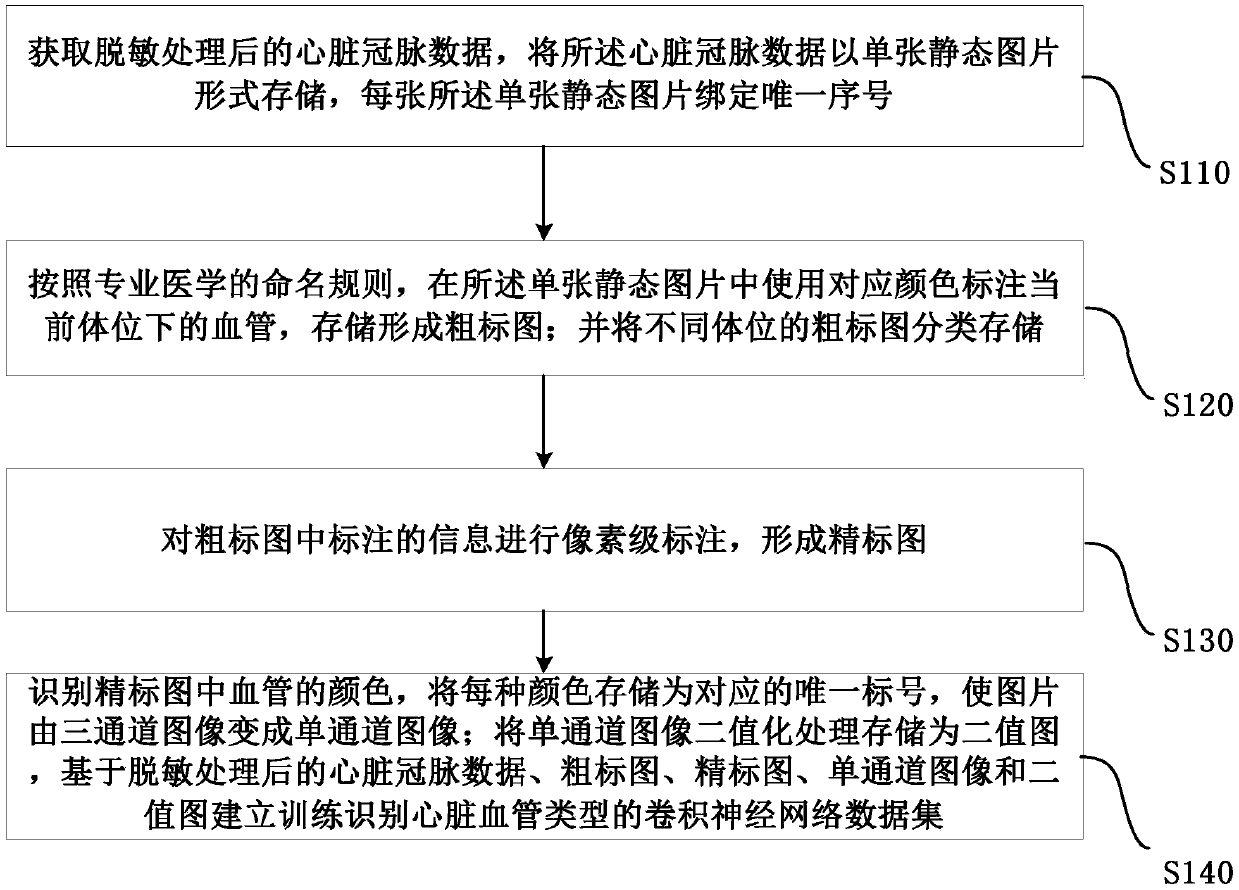

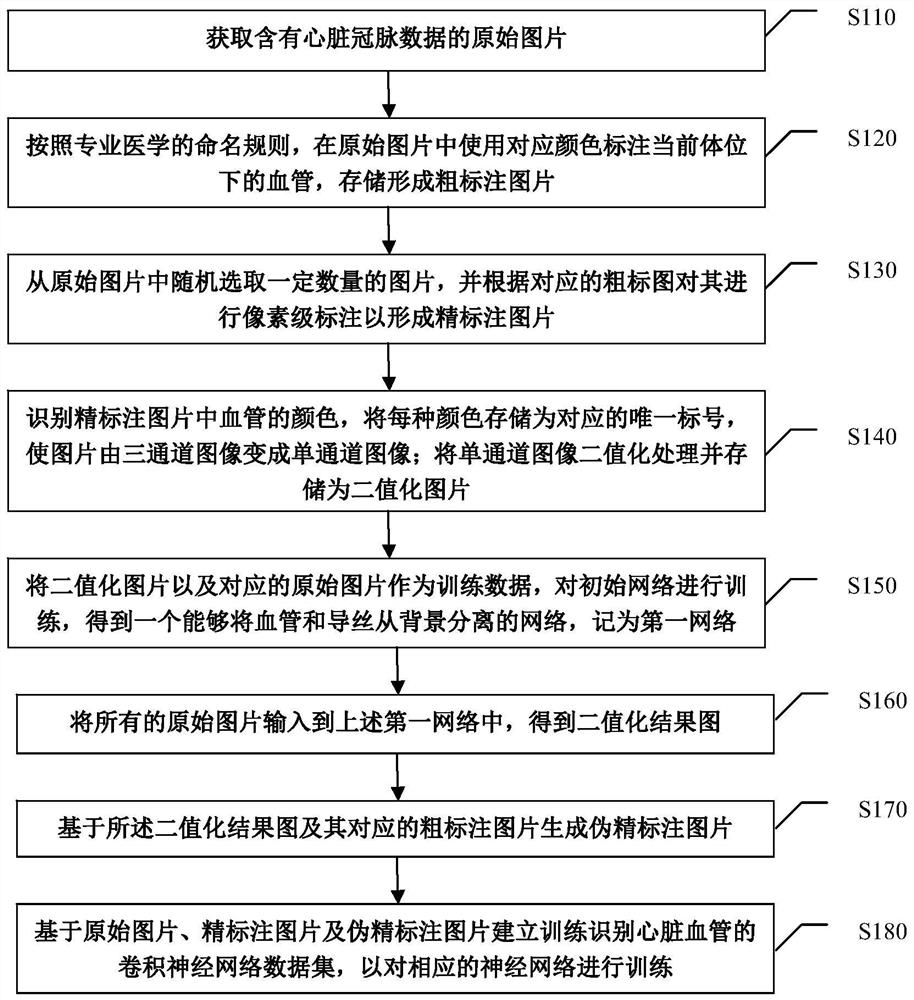

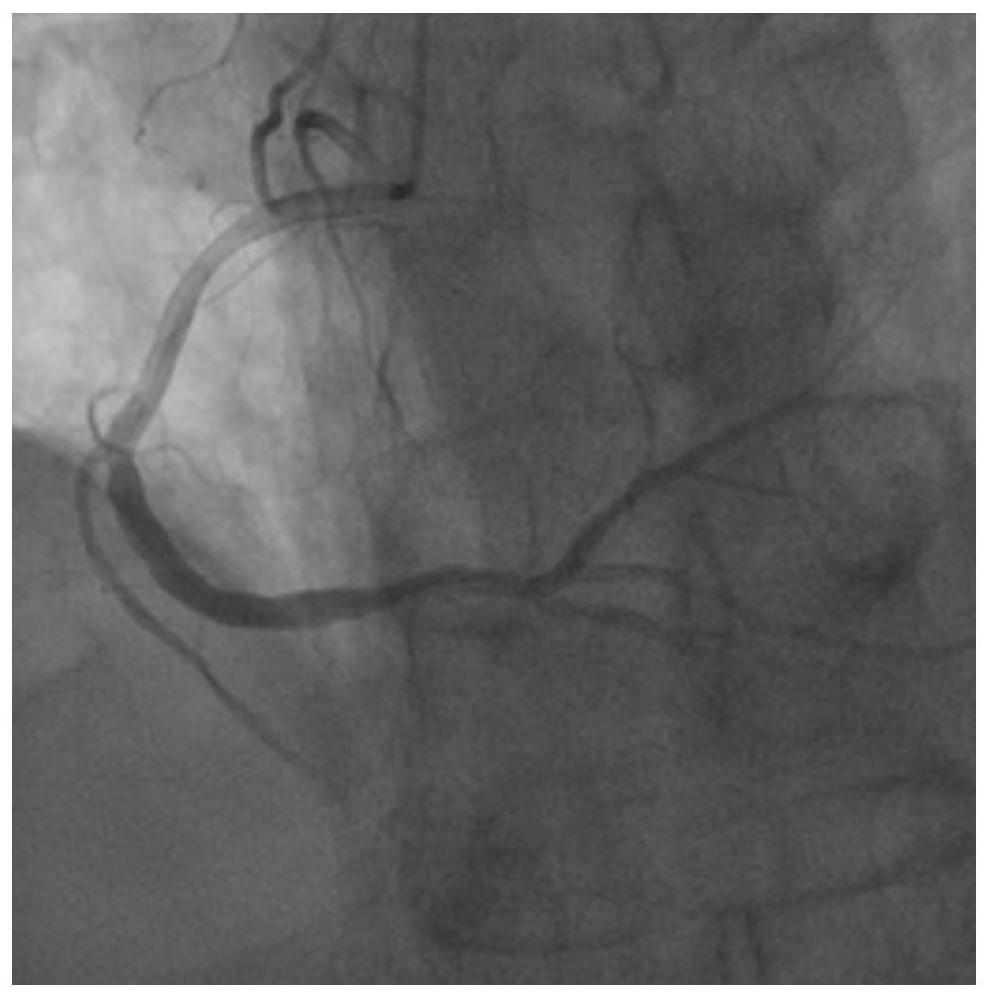

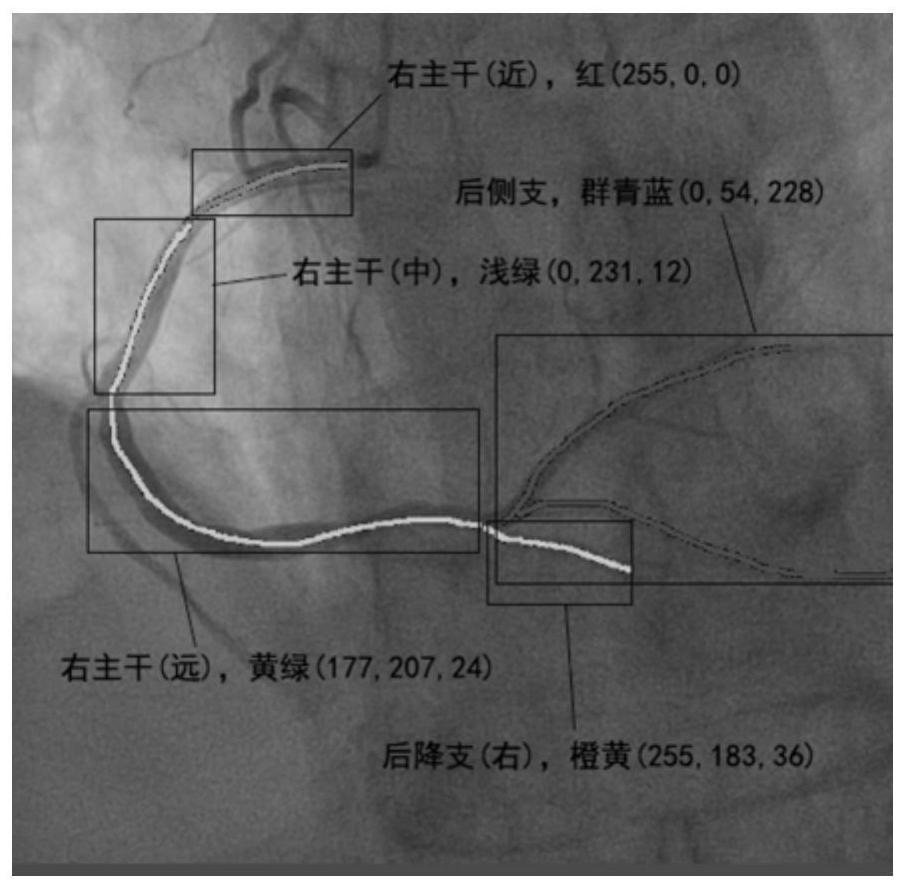

Method for establishing convolutional neural network data set for training and recognizing cardiac blood vessel type

ActiveCN108629773AReduce error rateBig amount of dataImage enhancementImage analysisCoronary arteriesData set

The invention discloses a method for establishing a convolutional neural network data set for training and recognizing a cardiac blood vessel type. The method comprises the steps that cardiac coronaryartery data after desensitization are acquired and stored in the form of a single static picture; in the single static picture, a corresponding color is used to mark a blood vessel under the currentbody position to form a coarse plot; pixel level marking is carried out on information marked in the coarse plot to form a fine plot; the color of the blood vessel in the fine plot is recognized, so that the picture becomes a single-channel image from a three-channel image; the single-channel image is stored as a binary image; and based on the desensitized cardiac coronary artery data, the coarseplot, the fine plot, the single-channel image and the binary image, the convolutional neural network data set which trains and recognizes the cardiac blood vessel type is established. According to theinvention, unified processing is carried out on the data; the data in the data set are real and diverse; the data set has the advantages of large data volume, rich data type, standard format and small error rate, and can be used for training neural networks with different functions; and manual intervention is reduced.

Owner:北京红云智胜科技有限公司 +1

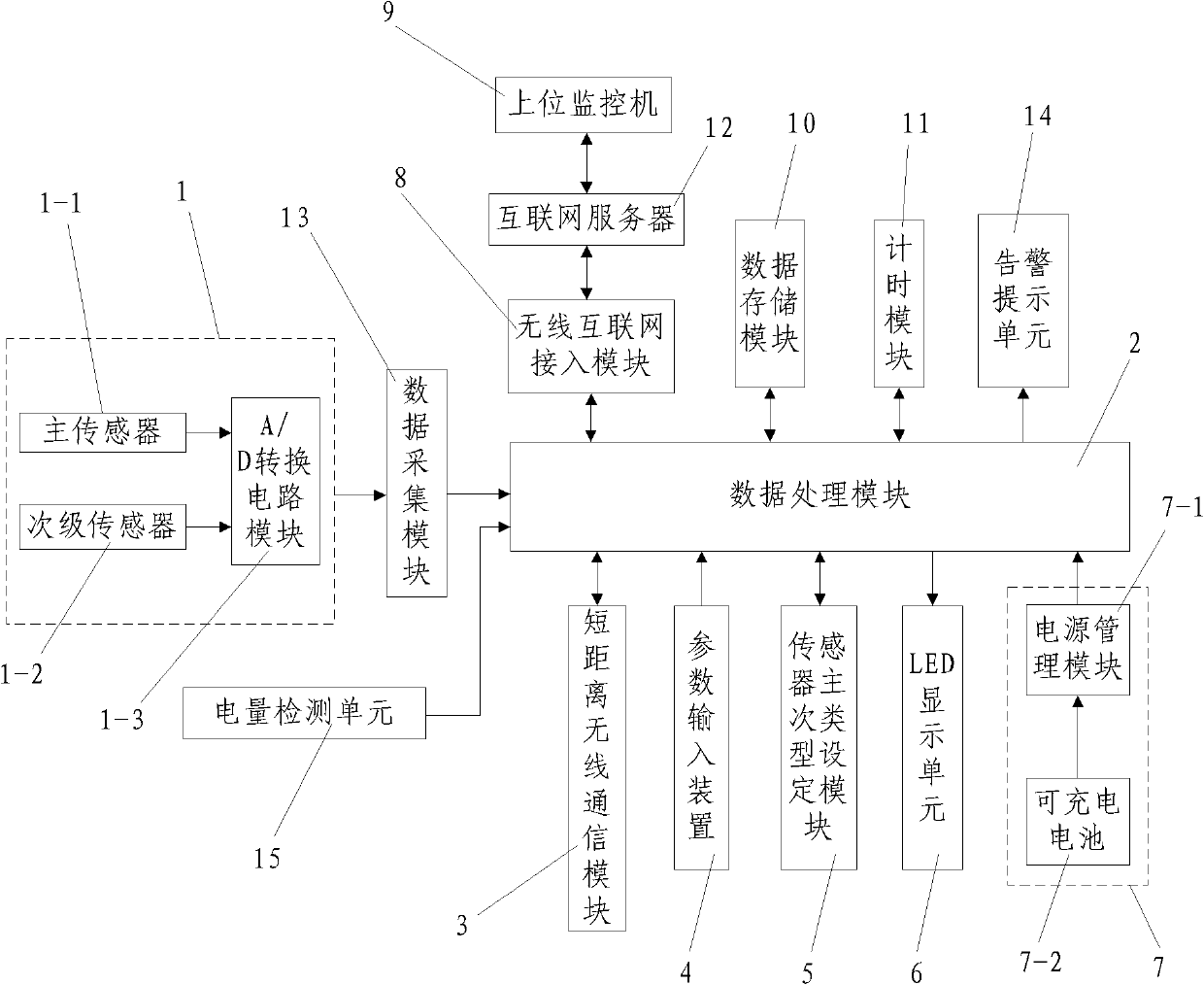

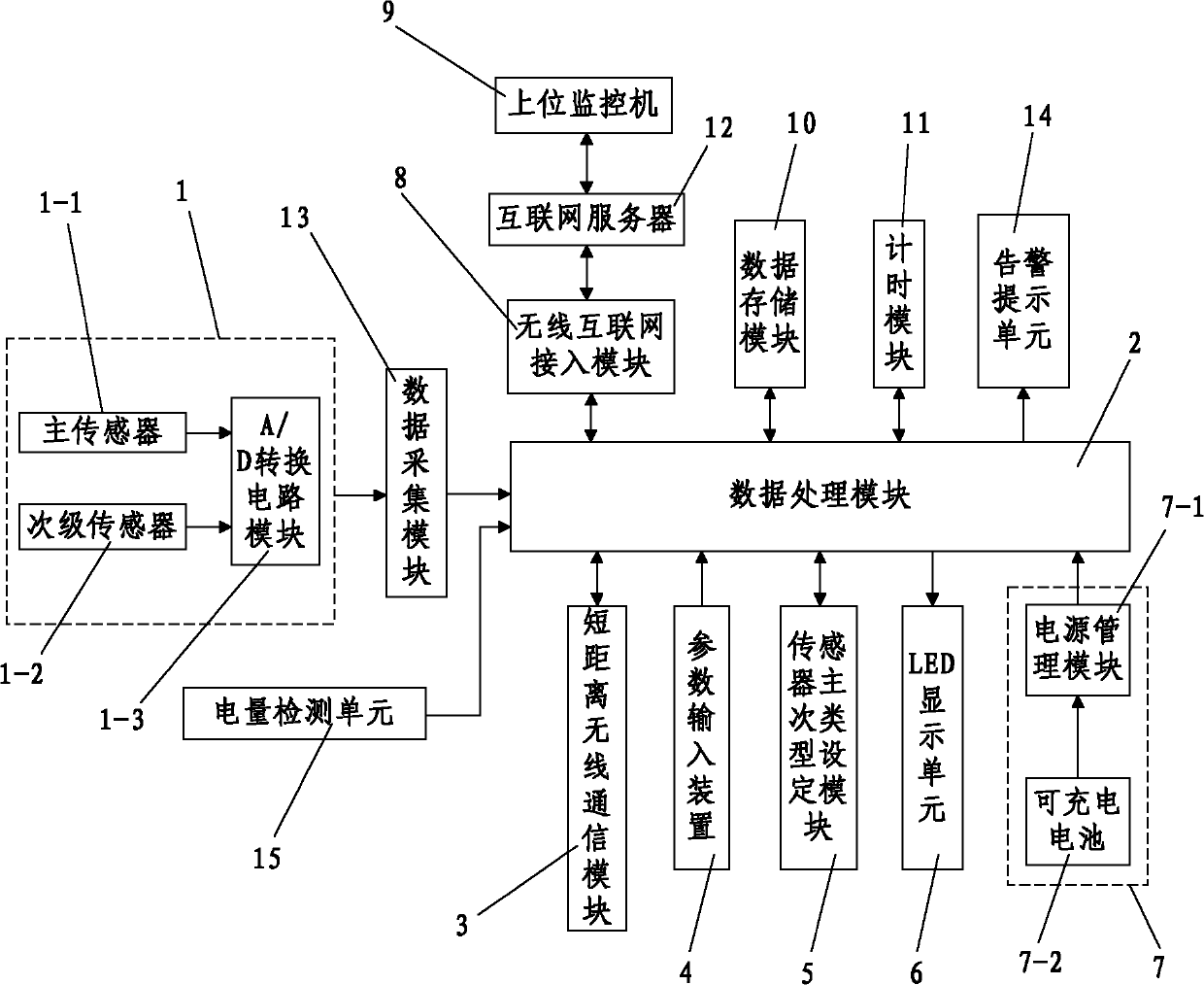

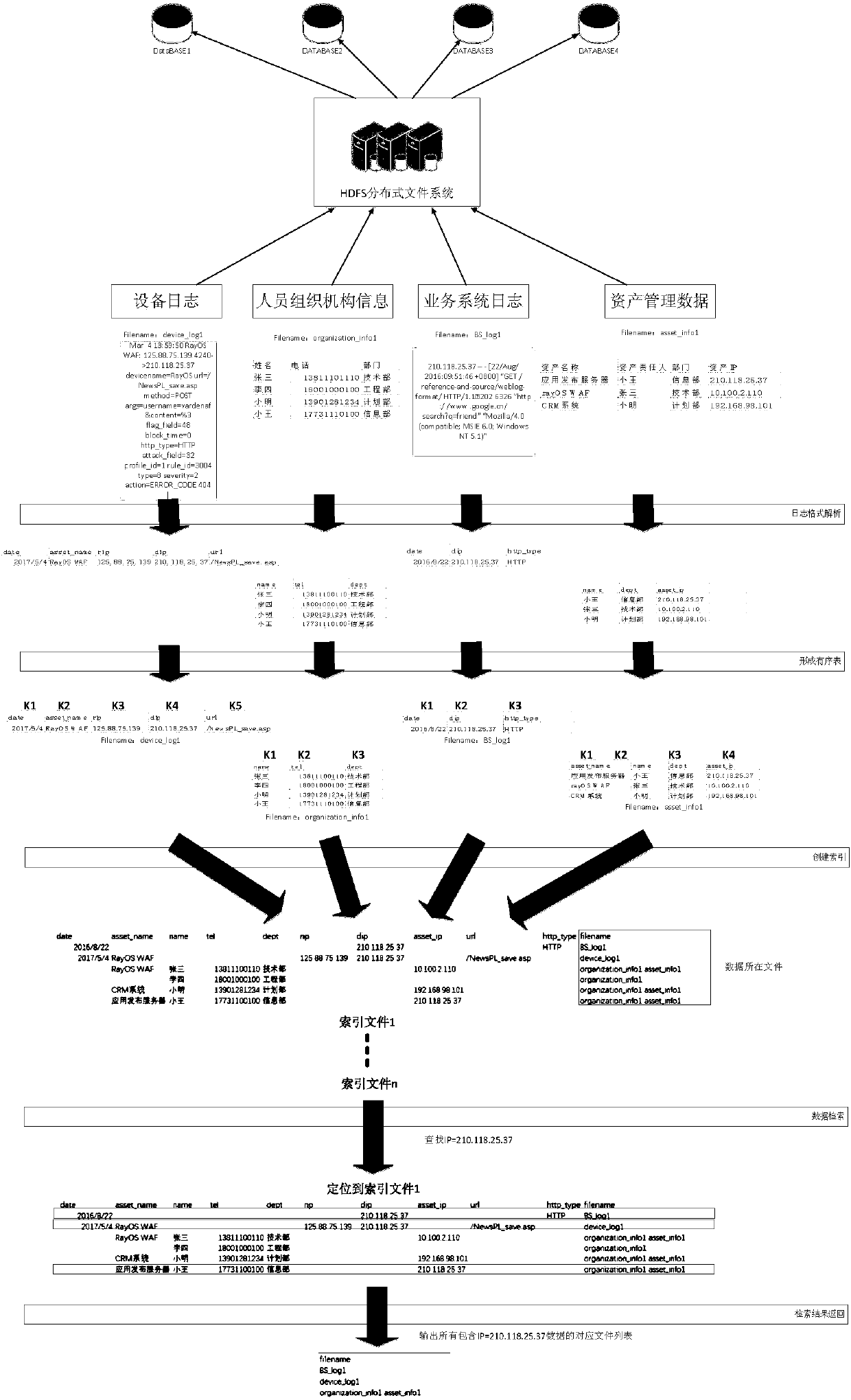

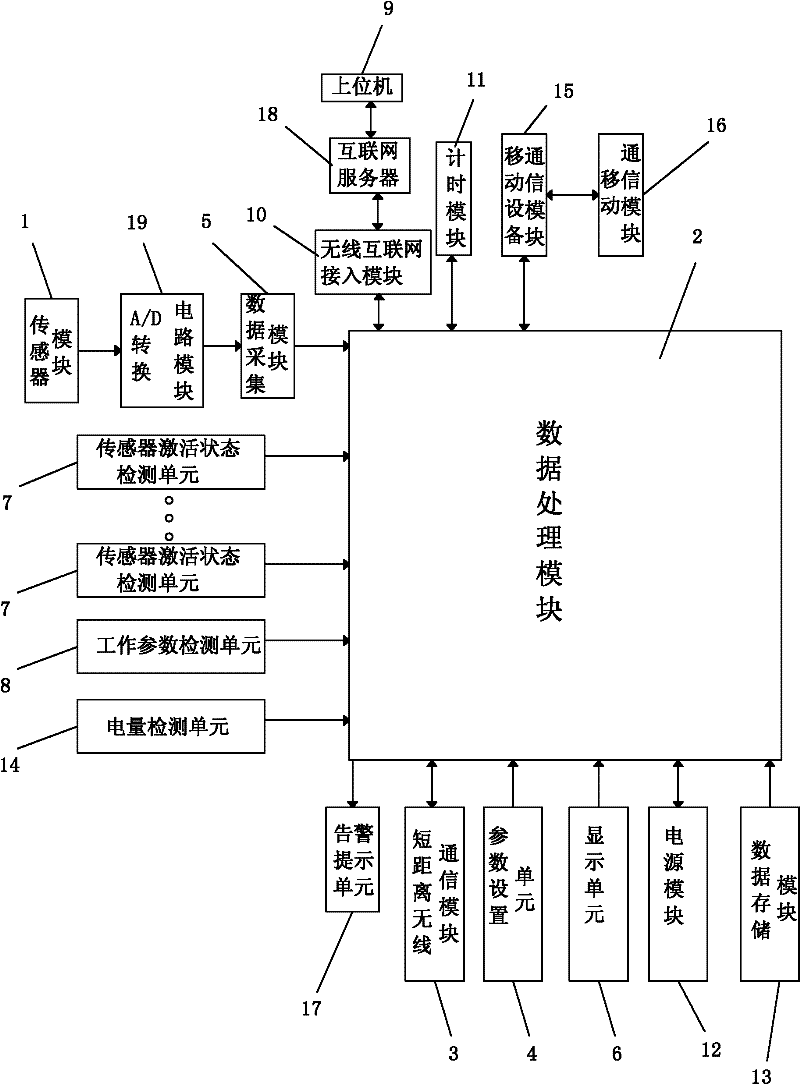

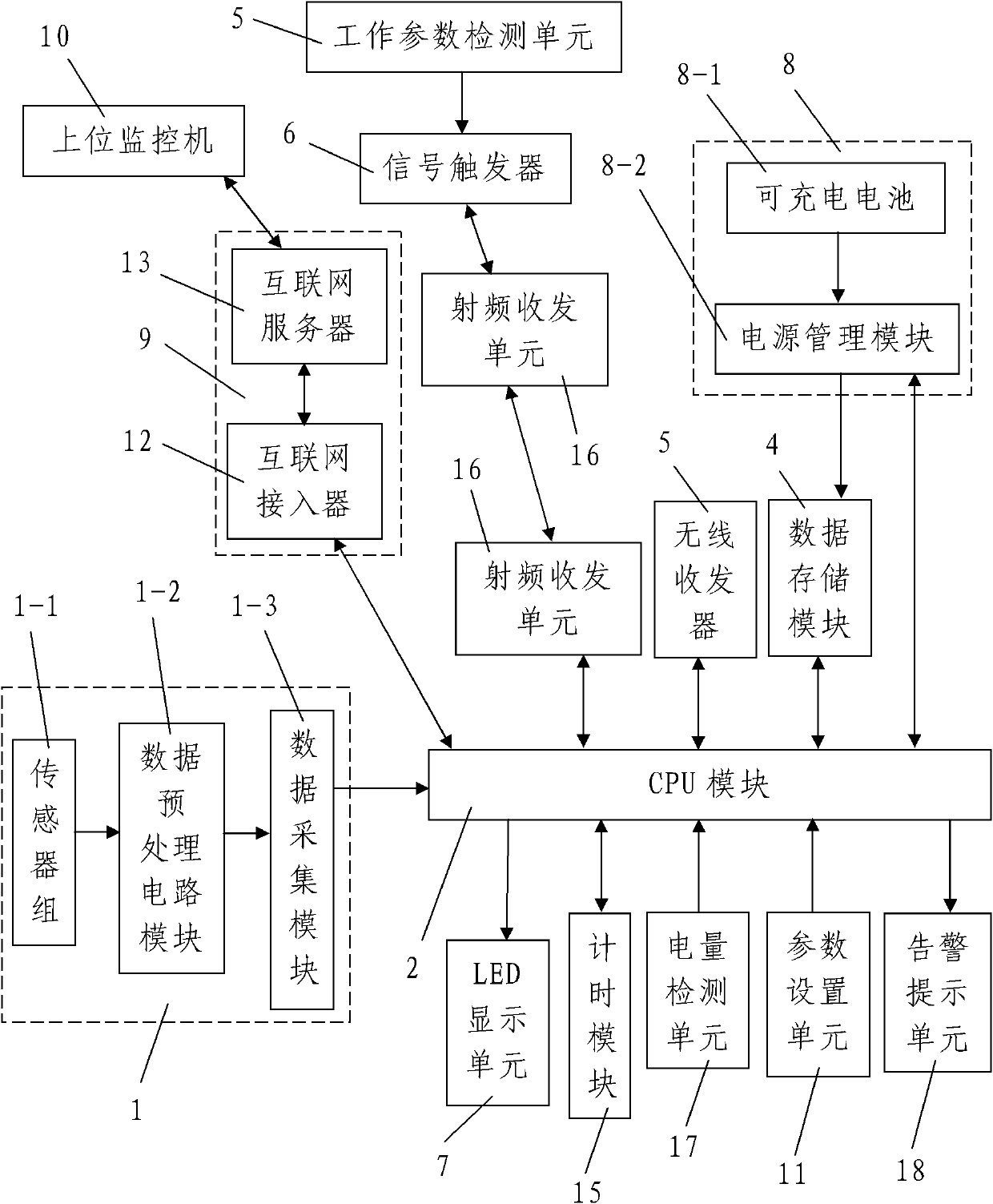

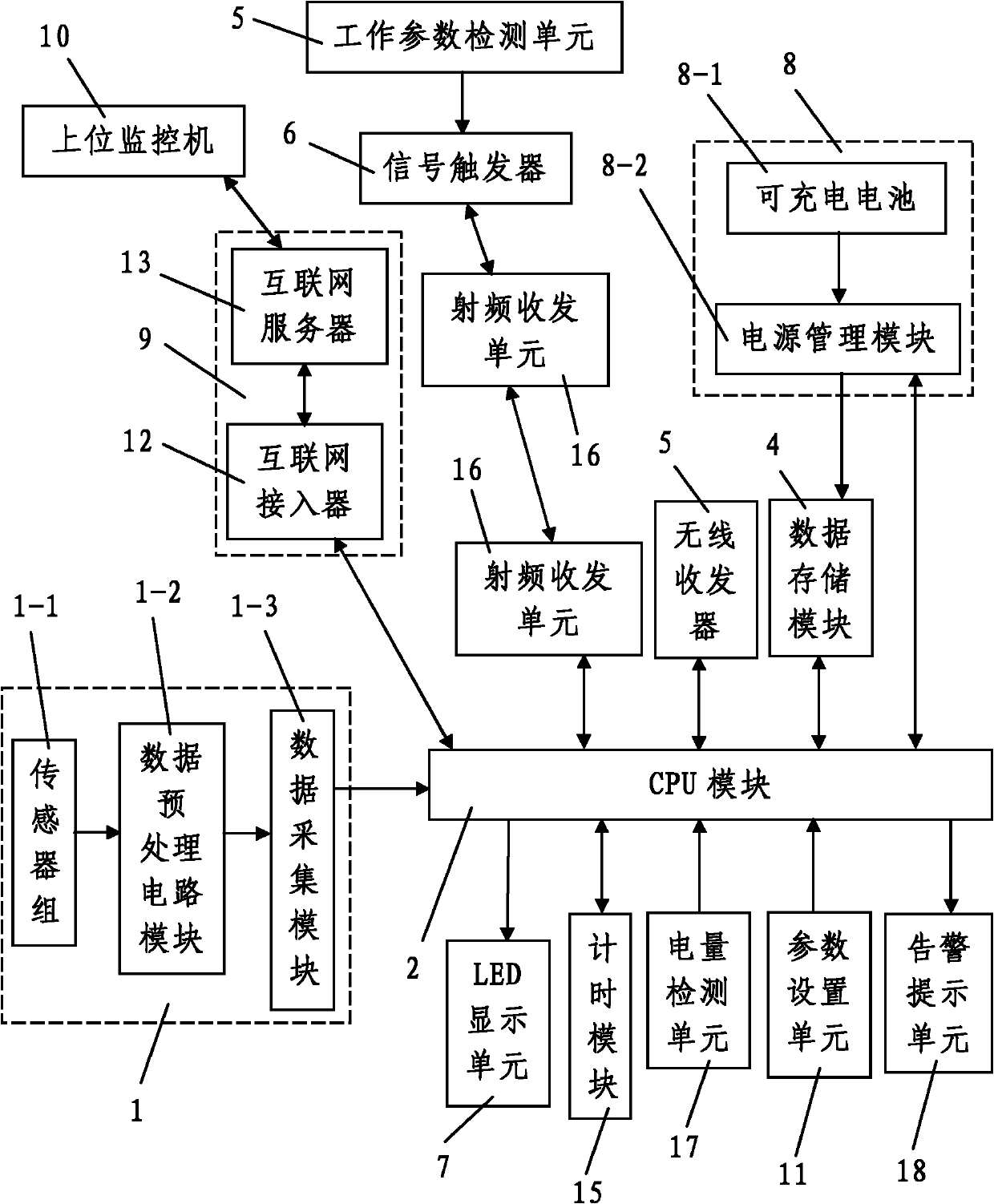

Multi-parameter monitoring using wireless sensor node with self-triggering function

InactiveCN102573118AStrong real-timeRich data typesNetwork topologiesShortest distanceData acquisition

The invention discloses a multi-parameter monitoring using wireless sensor node with a self-triggering function, which comprises a sensor module, a short-distance wireless communication module, a data processing module, a parameter input device, an LED display unit synchronously displaying information acquired by sensors in the sensor module and keeping an operation state, a sensor primary and secondary type setting module used for setting the primary and the secondary types of the sensors, a data storage module, a power supply module and a wireless transmitting / receiving module, wherein the plurality of sensors include primary sensors activated by the data processing module and secondary sensors activated by the data processing module based on the information detected by the primary sensors. The wireless sensor node provided by the invention has a reasonable design, is convenient to network and maintain, simple and easy to operate, good in use effect, and high in degree of intelligence, and the plurality of sensors in the sensor module are divided into the primary sensors and the secondary sensors, so that the energy consumption of the node is lowered, and besides, the data acquisition efficiency and the data processing ability of the node are greatly improved.

Owner:XIAN CENTN TECH

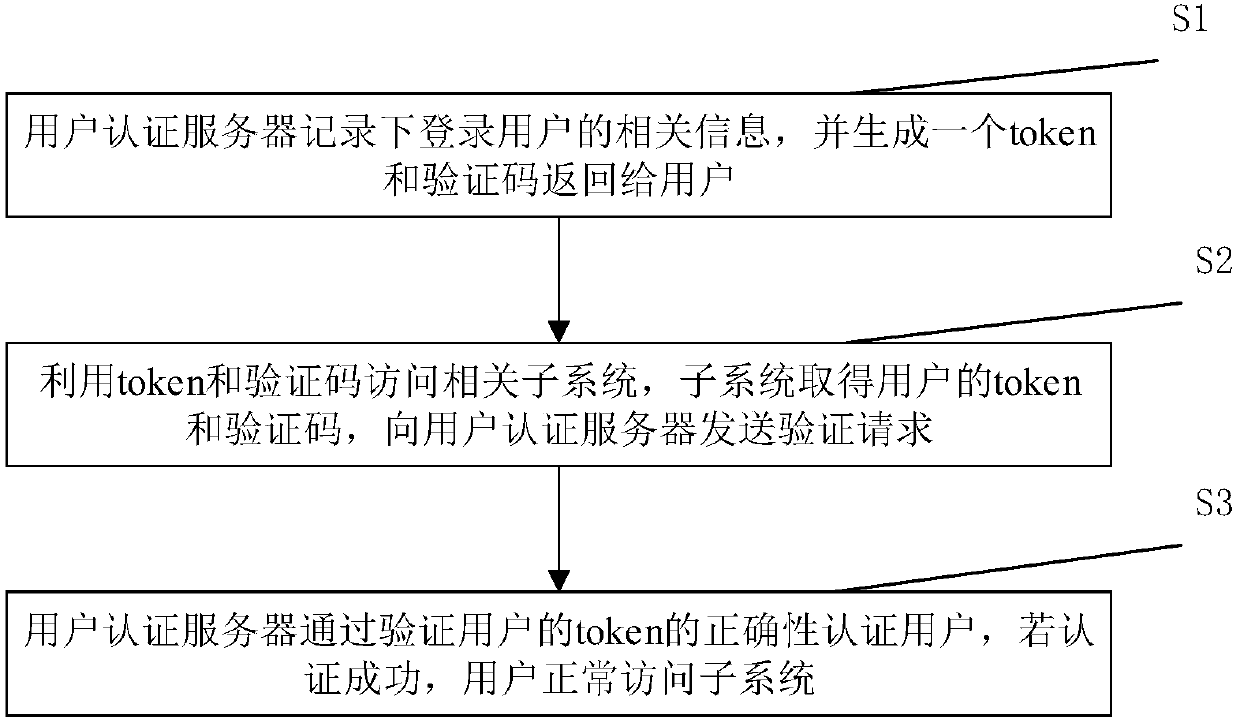

Method for integrating multiple web systems

InactiveCN108040090ASave manpower development costsIntegrity guaranteedTransmissionSystem integrationRelevant information

The invention relates to a method for integrating multiple web systems. The method comprises the following steps: S1, enabling a user authentication server to record related information of a login user and generate a token and a verification code to return to the user; S2, accessing a related subsystem by using the token and the verification code, and enabling the subsystem to get the token and the verification code of the user and send a verification request to the user authentication server; and S3, enabling the user authentication server to authenticate the user by verifying correctness ofthe token of the user and if the authentication is successful, enabling the subsystem to get related information of the user in the subsystem to return to the user; or otherwise, returning authentication failed information and enabling an interface to return to a login interface. Compared with the prior art, according to the method, the multiple web systems are integrated via single point login, and the difficult problem of multi-system integration is solved by employing a minimum manpower; and on the premise of guaranteeing the integrity and the correctness of an original system as much as possible, the manpower development cost required for software integration is greatly saved.

Owner:SHANGHAI SIIC LONGCHUANG SMARTER ENERGY TECH CO LTD

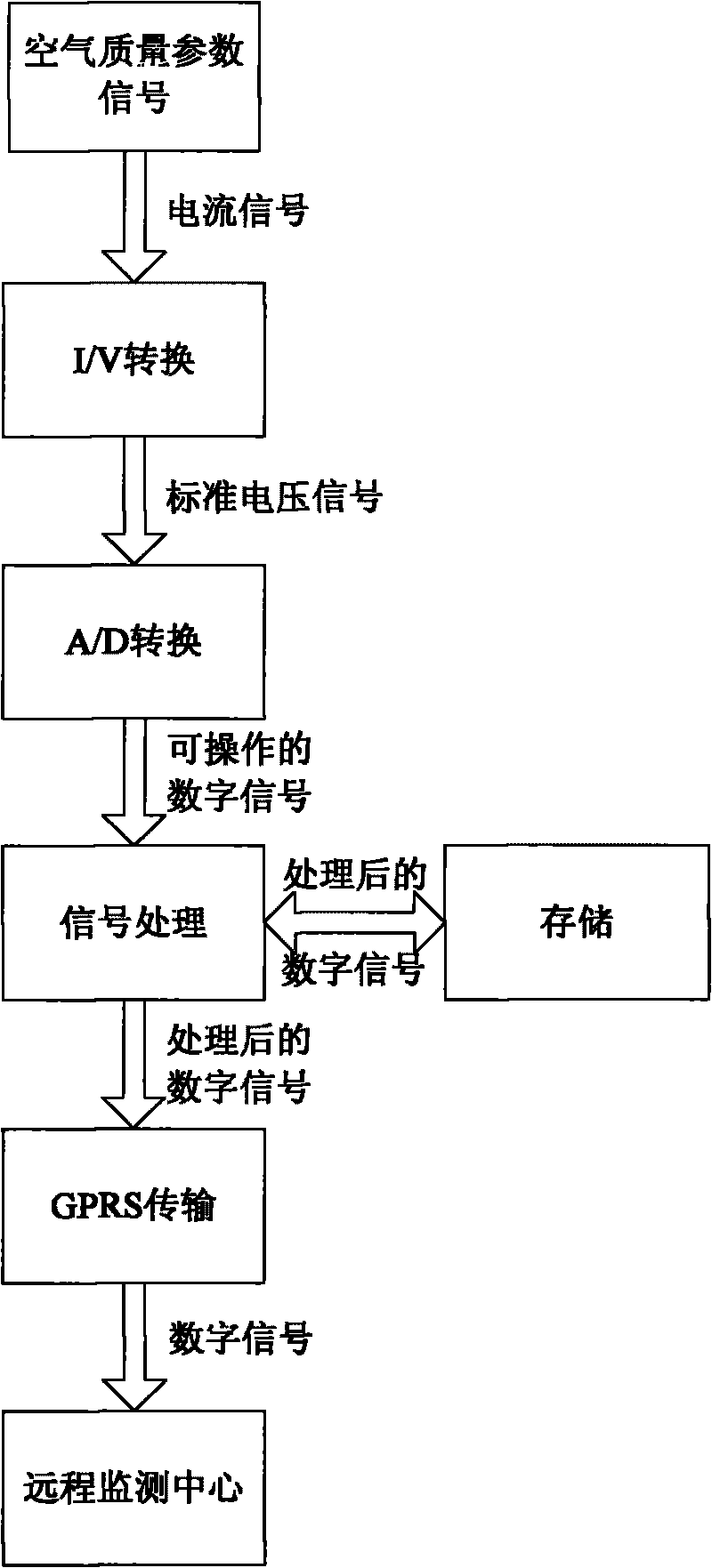

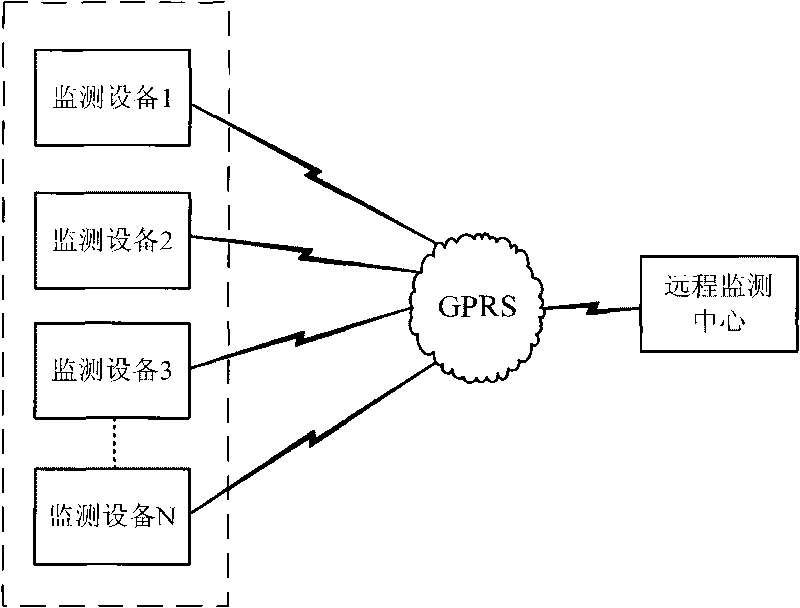

Air quality monitoring equipment capable of supporting data remote transmission

InactiveCN101701952AEasy to deployStrong real-timeTransmission systemsMaterial analysisTransducerEngineering

The invention relates to air quality monitoring equipment capable of supporting data remote transmission. The traditional equipment has high cost and limited monitoring range. The air quality monitoring equipment capable of supporting data remote transmission comprises a power source management module, an air quality parameter acquisition module, a microprocessor module and a GPRS transmission module, wherein the power source management module supplies power for the air quality parameter acquisition module, the microprocessor module and the GPRS transmission module; a plurality of transducers in the air quality parameter acquisition module output signals to the microprocessor module after passing through an I / V conversion circuit; and the GPRS transmission module is connected with a USART interface of the microprocessor module. The invention has strong real-time, various data types, wide coverage area, strong communication capacity and high transmission speed.

Owner:HANGZHOU DIANZI UNIV

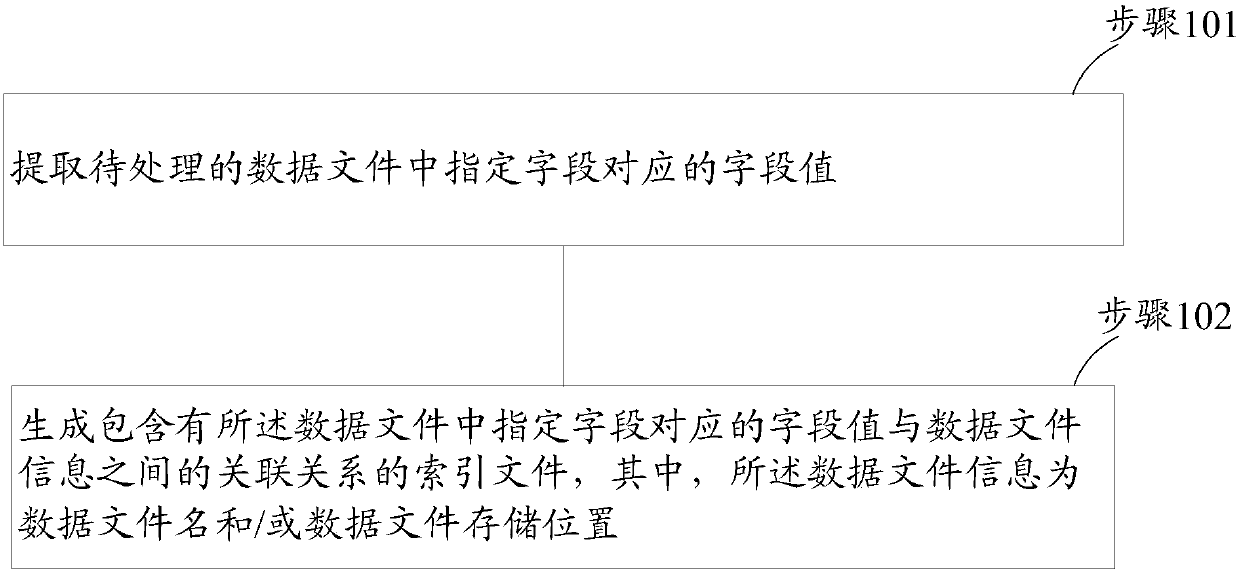

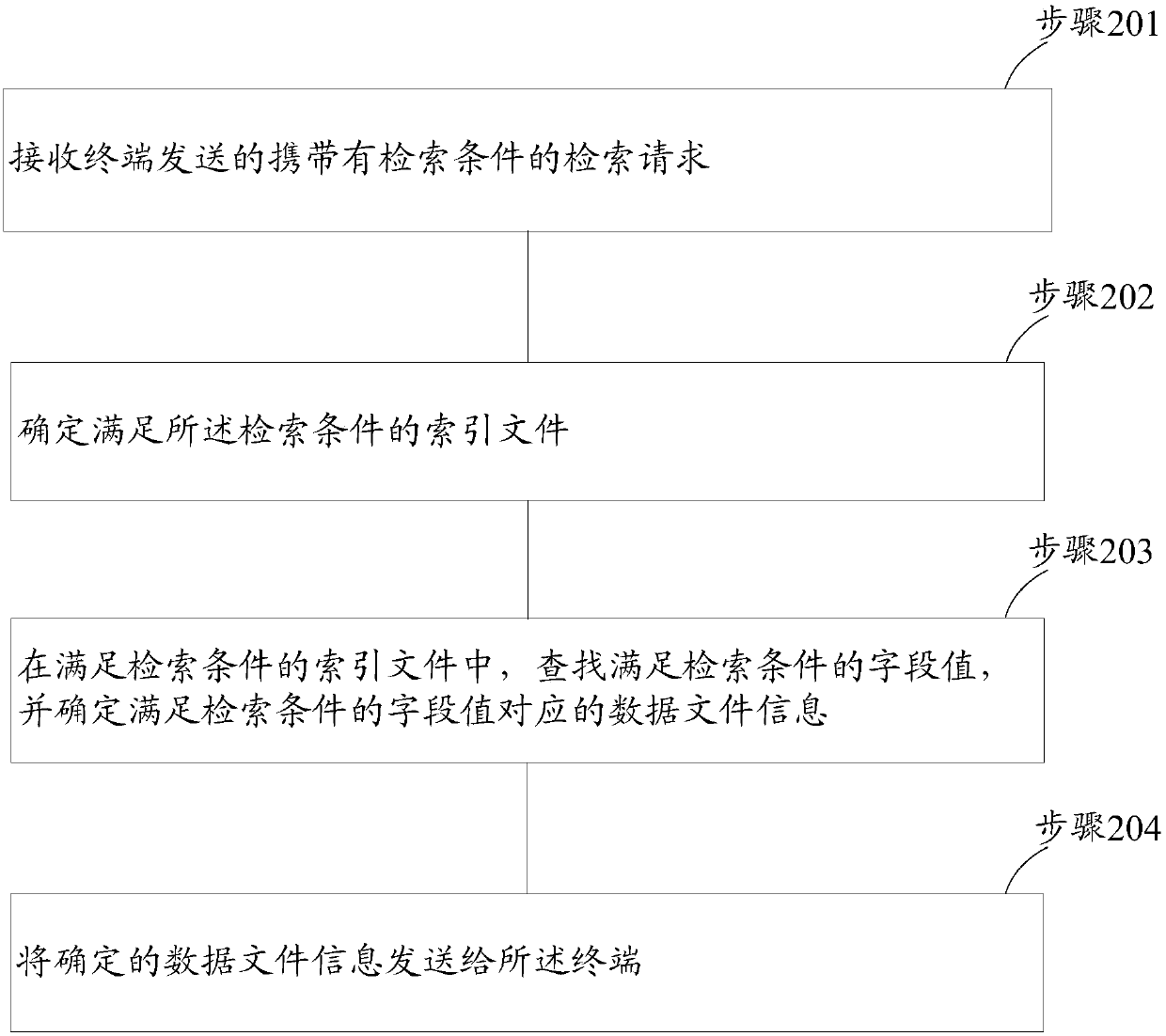

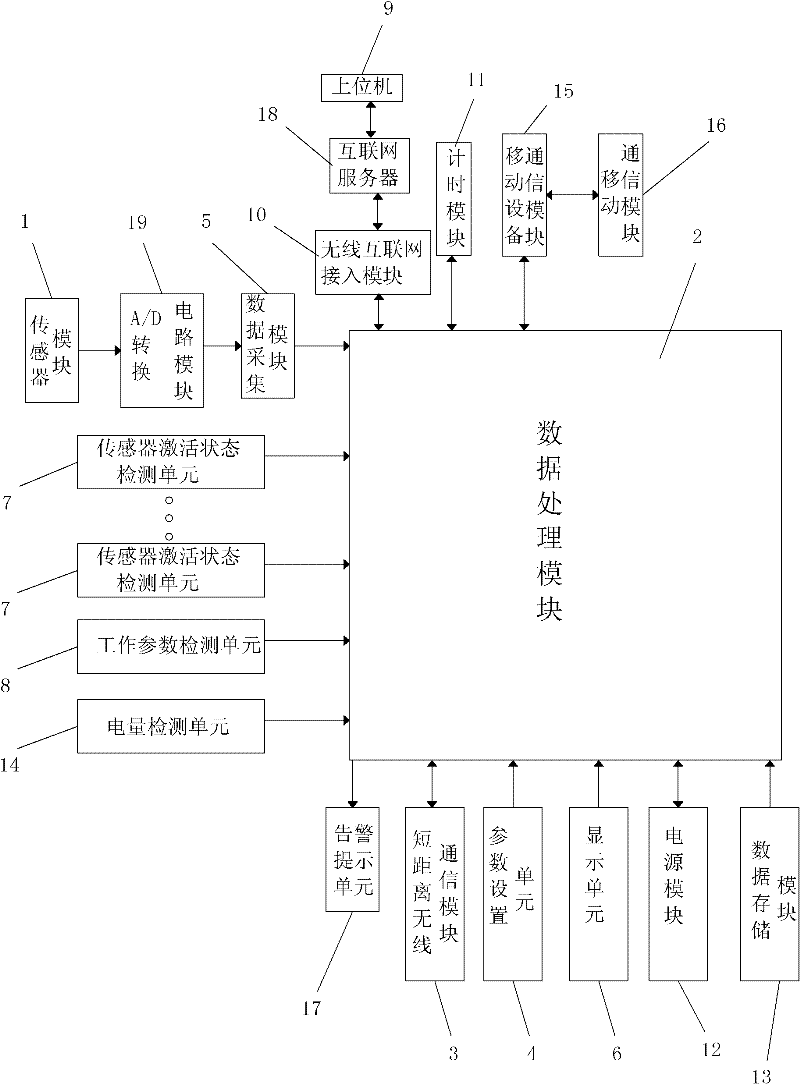

Data index establishment method and device and index retrieval method and device

InactiveCN109947759ARich data typesBig amount of dataDatabase queryingDatabase indexingBig dataIndexed file

The invention relates to the technical field of data storage and management, in particular to a data index establishment method and device and an index retrieval method and device, and is used for solving the problems that an existing index mode cannot be suitable for a mass data environment and high-efficiency batch deletion is very difficult to achieve. The data index establishing method provided by the embodiment of the invention comprises the following steps: extracting a field value corresponding to an appointed field in a to-be-processed data file; And generating an index file containingan association relationship between a field value corresponding to a specified field in the data file and data file information, the data file information being a data file name and / or a data file storage position.

Owner:CHINA MOBILE GROUP JILIN BRANCH +1

Wireless sensor node with automatic inspection function

InactiveCN102548031AStrong real-timeRich data typesNetwork topologiesTransmissionData memorySensor node

The invention discloses a wireless sensor node with an automatic inspection function, which comprises a sensor module, a data processing module, a short-range wireless communication module, a wireless transceiver / receiver module, a data memory module, a display unit which synchronously displays the detected information of the sensor module, the inspection result of a sensor activation state and the relevant working parameters of the data processing module, a power module, and an automatic inspection unit which consists of a plurality of sensor activation state detection units, a working parameter detection unit, a timing module, a power detection unit, the timing module and the data processing module and periodically and automatically inspects the wireless sensor node. The wireless sensor node has a reasonable design, the network is convenient to distribute and maintain, the wireless sensor node is simple to operate, and has a good use effect and high intelligent degree, the automatic inspection unit periodically and automatically inspects the wireless sensor node through automatic inspection, all the sensors in the sensor node can be effectively ensured to normally and orderly work, and the inspection effect is directly displayed.

Owner:XIAN CENTN TECH

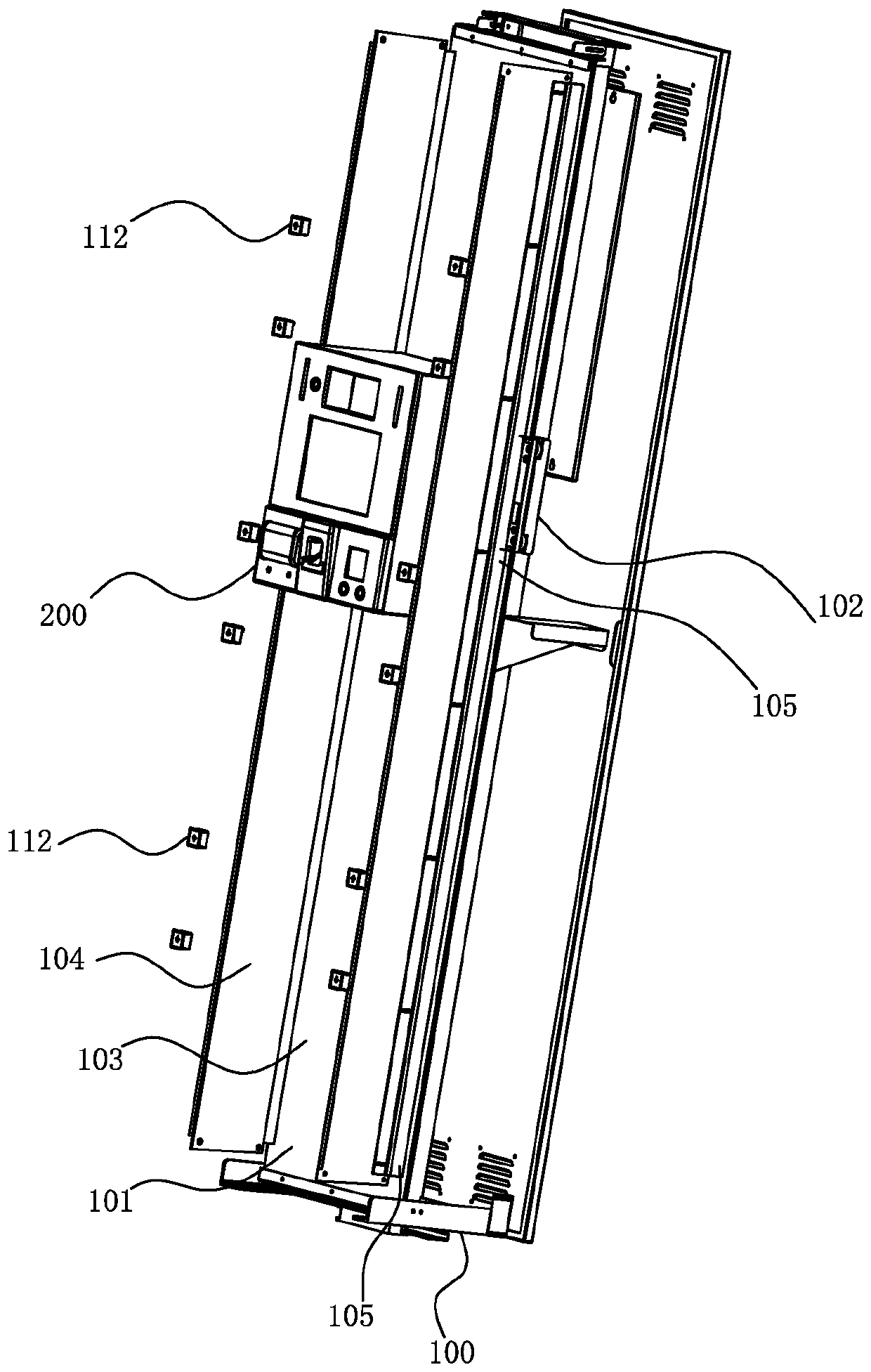

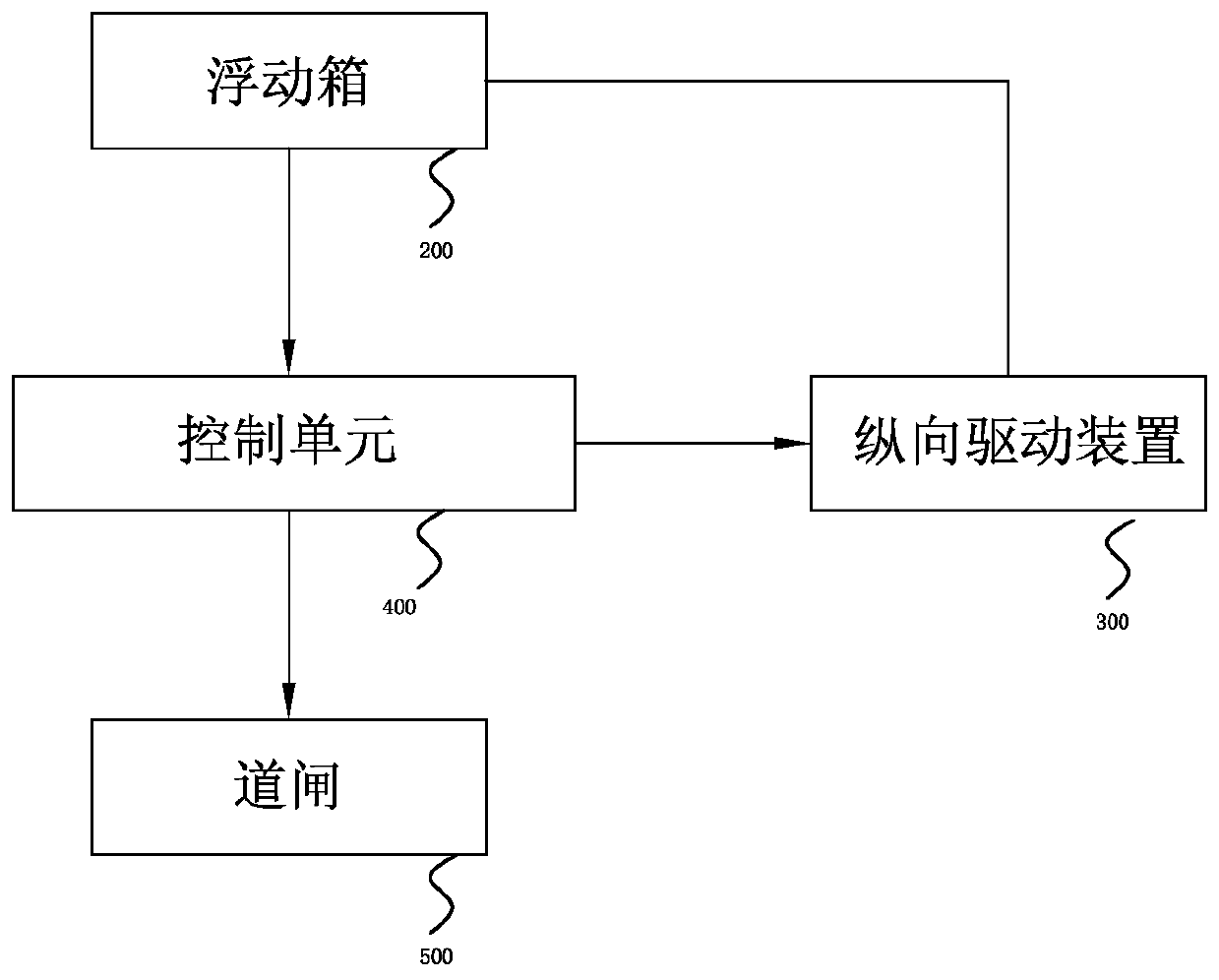

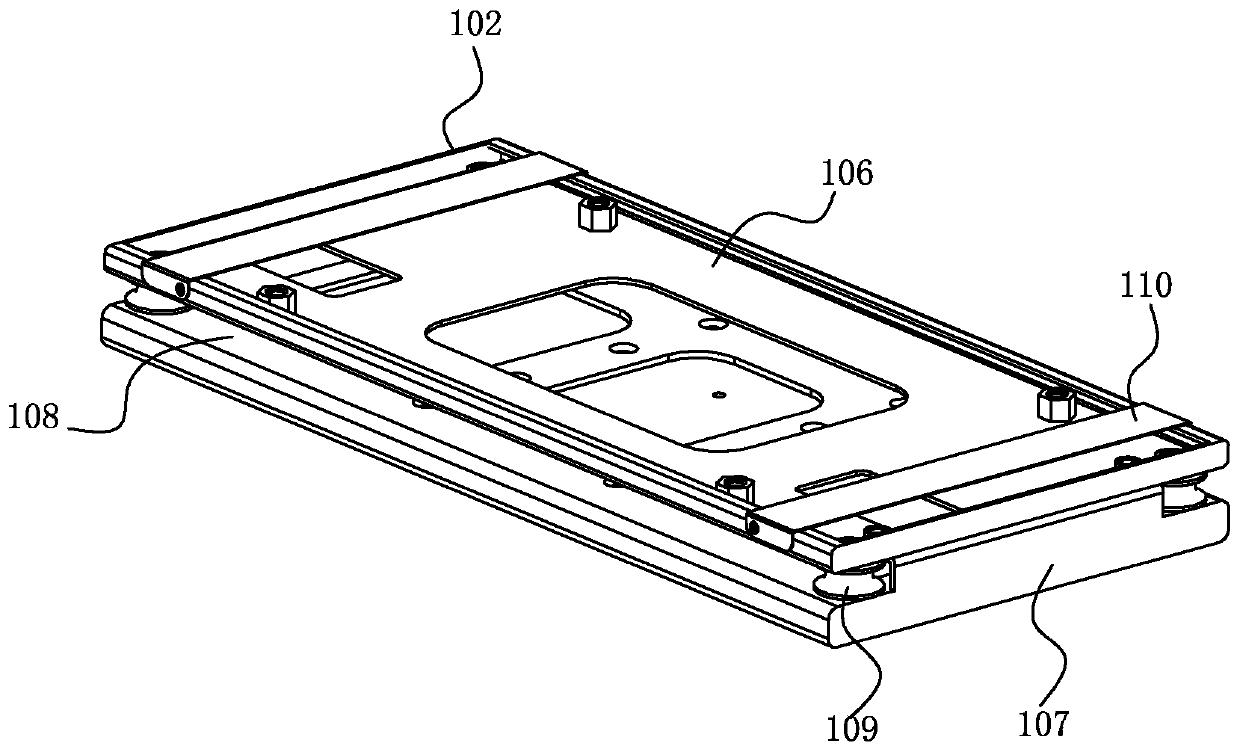

Embedded intelligent telescopic integrated cabinet

PendingCN110864813AImprove the level of informatizationAchieve positioningRadiation pyrometryIndividual entry/exit registersStructural engineeringMechanical engineering

The invention discloses an embedded intelligent telescopic integrated cabinet, and the cabinet comprises a cabinet frame, a first function module installed on the cabinet frame and a second function module installed on the cabinet frame. The first function module comprises a first panel fixedly connected with the cabinet frame, a certificate reader installed on the first panel, a fingerprint instrument installed on the first panel, and a scanning reader-writer installed on the first panel and located on the side edge of the fingerprint instrument. The second function module comprises a secondpanel which is fixedly connected with the cabinet frame and is connected with the cabinet frame through an elastic hinge, a point touch screen which is arranged on the second panel, a glass structurewhich is arranged on the second panel and is positioned above the point touch screen, a rotary door which is installed on the second panel and located on the right side of the glass structure, a roundglass structure which is installed on the second panel and located on the left side of the glass structure, and an ultrasonic probe which is installed on the second panel and located on the right side of the rotary door, so the labor intensity and personal injury risks of inspection and quarantine personnel are greatly reduced.

Owner:深圳市软筑信息技术有限公司

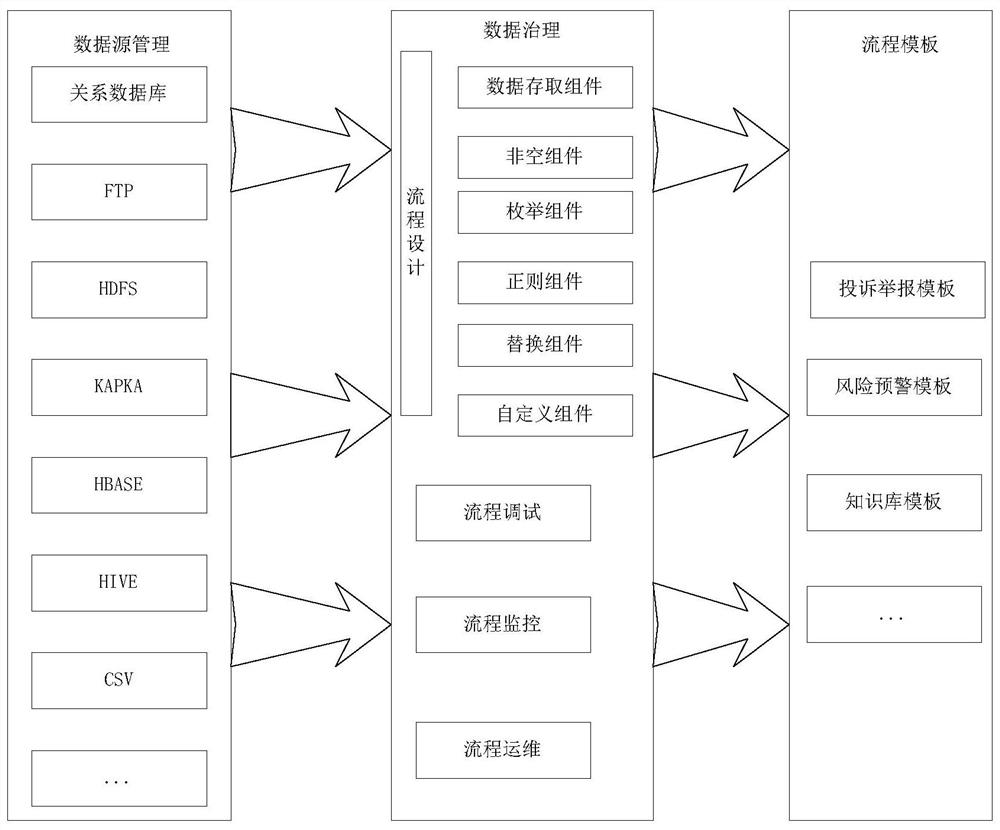

Multi-data-source dynamic data synchronous treatment method and system based on Internet supervision

PendingCN112925767AValue maximizationQuick buildDatabase management systemsOffice automationData synchronizationData connection

The invention discloses a multi-data-source dynamic data synchronous treatment method and system based on Internet supervision, belongs to the field of Internet + supervision, and aims to solve the technical problem of how to help a user to quickly construct a big data processing analysis process and realize low-cost quick construction of a data center. According to the technical scheme, data trends of various structured data, semi-structured data and unstructured data are fused, and a one-stop data development environment, visual process design, rich data types and intelligent task monitoring are provided; a user can quickly construct a big data processing and analysis process and quickly construct a data center at low cost. The method specifically comprises the following steps: data source management: managing a data connection service; data flow design: defining each data processing flow as a data flow job, and managing the data processing flows through the data flow jobs; and template management: carrying out process migration and reuse.

Owner:SHANDONG LANGCHAO YUNTOU INFORMATION TECH CO LTD

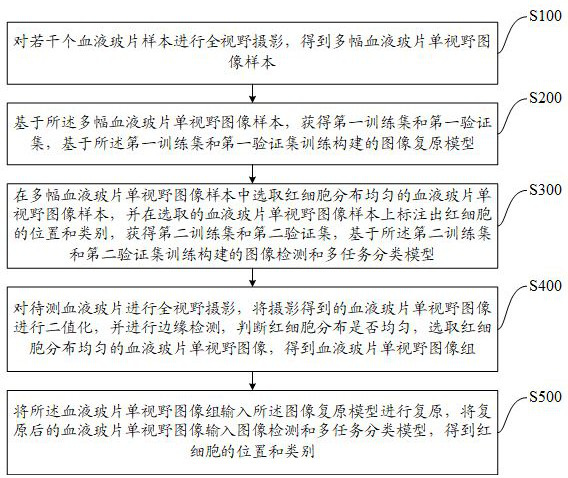

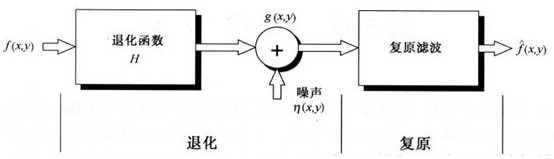

Red blood cell detection and classification method and device, computer storage medium and electronic equipment

ActiveCN114419619AThe results of the analysis are comprehensiveReduce distractionsAcquiring/recognising microscopic objectsNeural architecturesData setImage detection

The invention discloses a red blood cell detection and classification method and device, a computer storage medium and electronic equipment, and belongs to the field of blood cell detection. The method comprises the following steps: firstly, carrying out full-view photography on a large number of blood slides, and establishing a slide scanning image group; a training data set and a verification data set are prepared for an image restoration model, an image detection model and a multi-task classification model from a slide scanning image group. And performing model training by using deep learning and convolutional neural network technologies, and obtaining a final image restoration model, an image detection model and a multi-task classification model by continuously performing parameter tuning and error analysis optimization on the model. In the application process, a blood slide to be detected is also subjected to full-view photography, and a slide scanning image is established. And obtaining a restored clear slide scanning image through the image restoration model, and obtaining the position and category of the red blood cells through image detection and a multi-task classification model. According to the invention, erythrocyte detection and classification can be realized rapidly, comprehensively, accurately and objectively.

Owner:BEIJING XIAOYING TECH CO LTD

Automatic triggering type Ad hoc network node of wireless sensor network

InactiveCN102573138ALarge spreadHigh propagation speedWireless communicationWireless mesh networkShortest distance

The invention discloses an automatic triggering type Ad hoc network node of a wireless sensor network. The automatic triggering type Ad hoc network node comprises: a sensor module; a short-distance wireless communication module for automatically searching adjacent wireless sensor nodes; a CPU (Central Processing Unit) module; a working parameter detecting unit for detecting the working parameters of monitored equipment in real time; a signal trigger for transmitting the work instruction of a triggering sensor to the CPU module according to information detected by the working parameter detecting unit; an LED (Light Emitting Diode) display unit; a parameter setting unit; and a power supply unit and a wireless transceiving module which are connected with the CPU module. The CPU module conducts two-way communication with an upper monitoring computer through the wireless transceiving module; and the signal trigger conducts two-way communication with the CPU module in a wired or wireless way. The automatic triggering type Ad hoc network node is reasonable in design, convenient to distribute in network and maintain, easy and simple to operate, excellent in using effect, high in intelligent degree and capable of automatically triggering the sensor module by a triggering device which consists of the working parameter detecting unit and the triggering sensor.

Owner:XIAN LIANYOU ELECTRONICS TECH

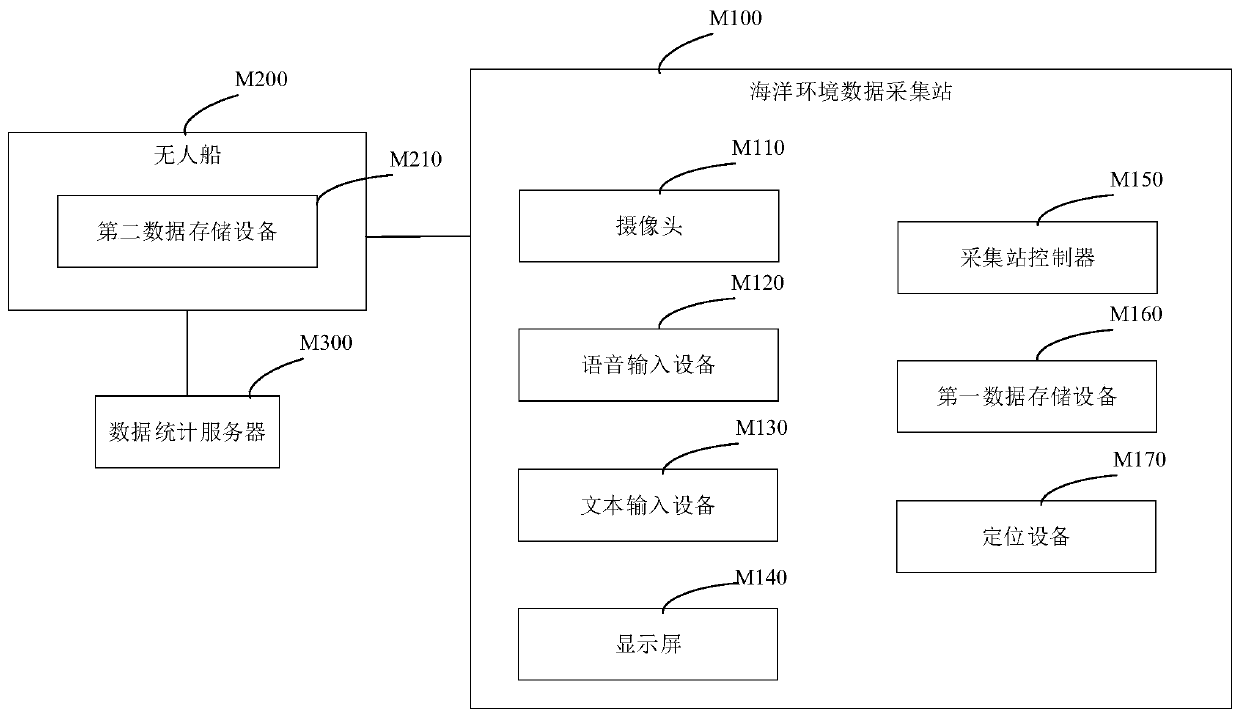

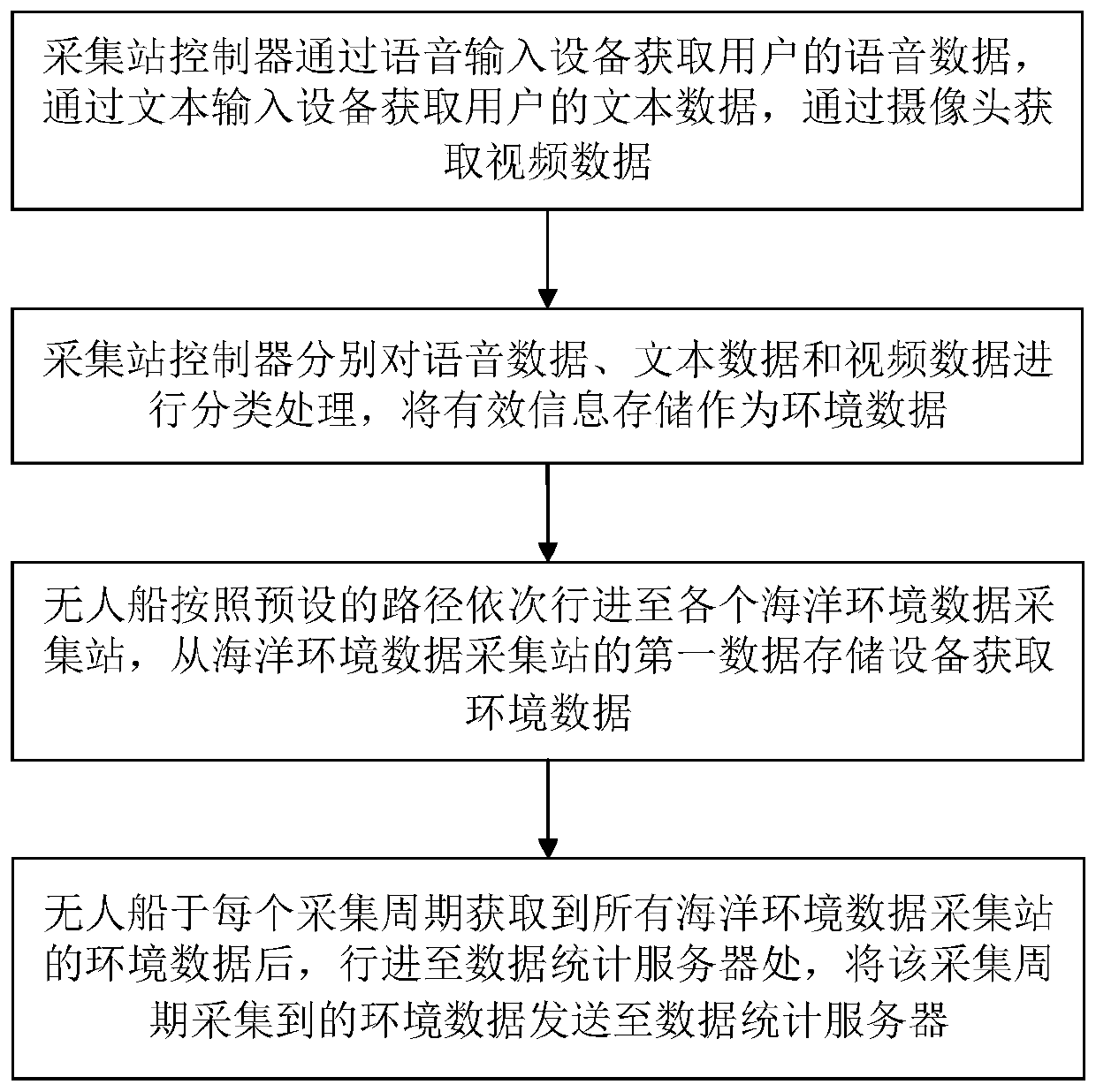

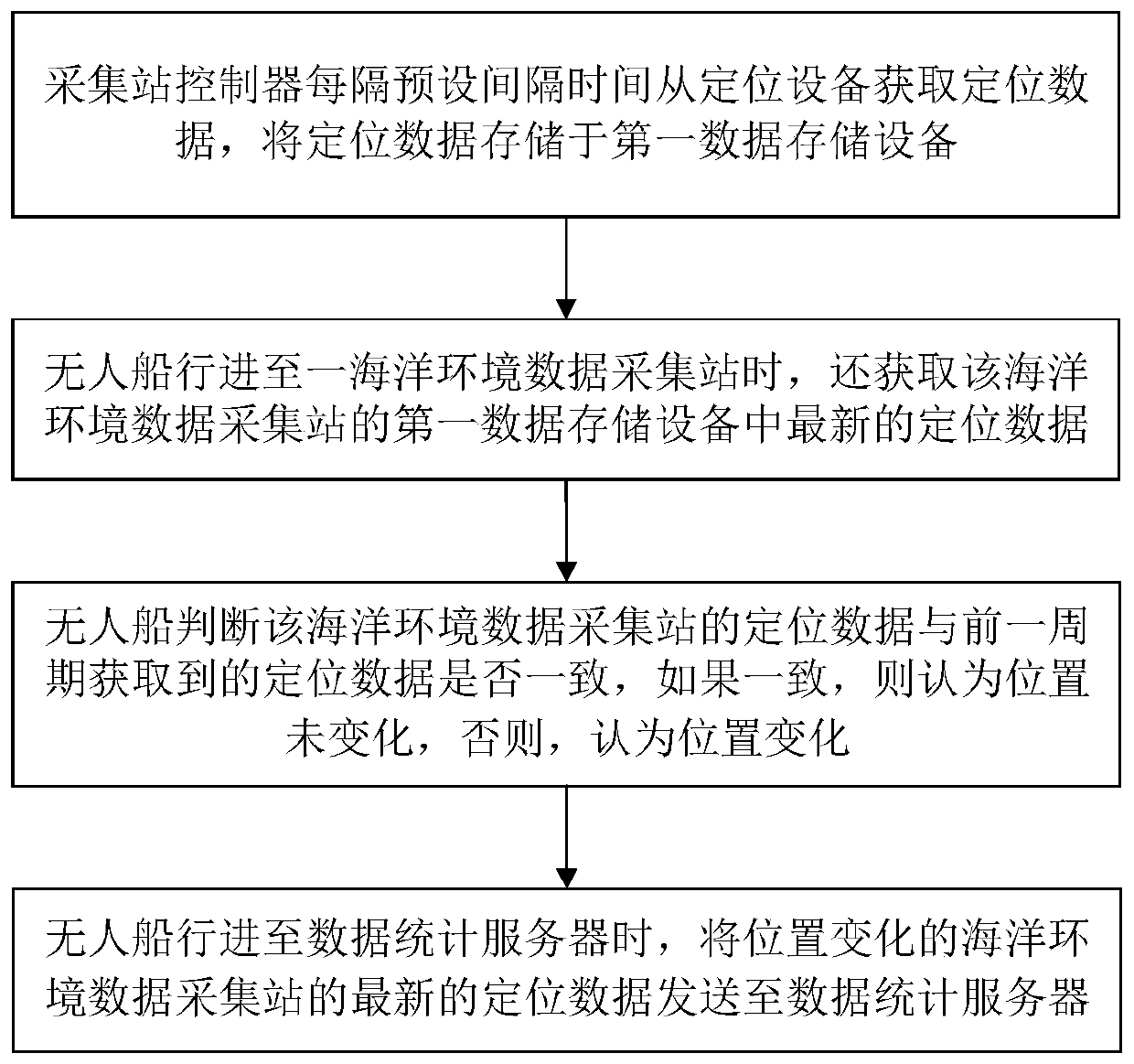

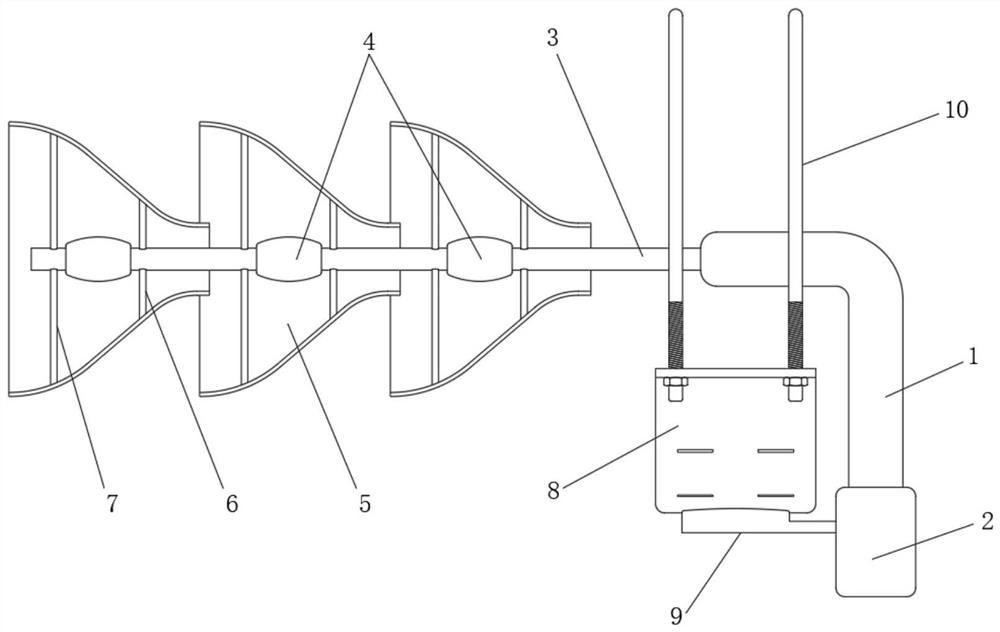

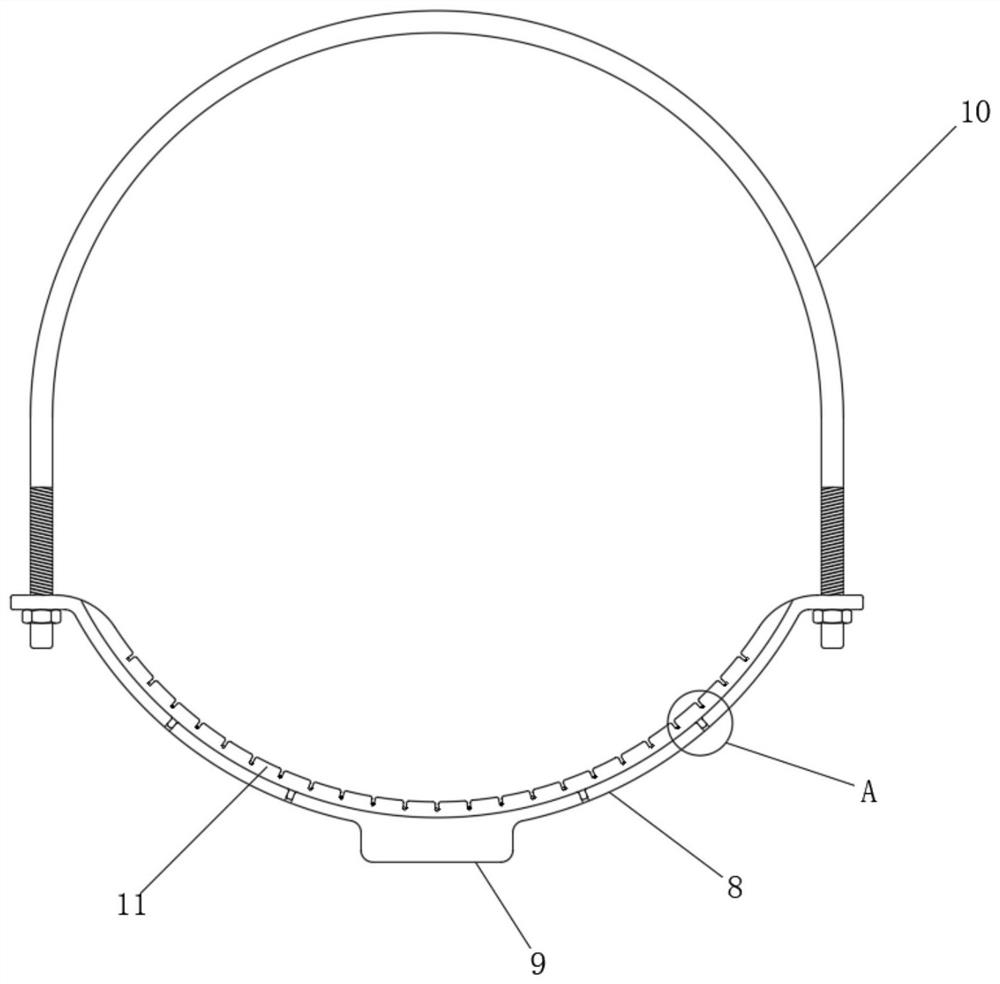

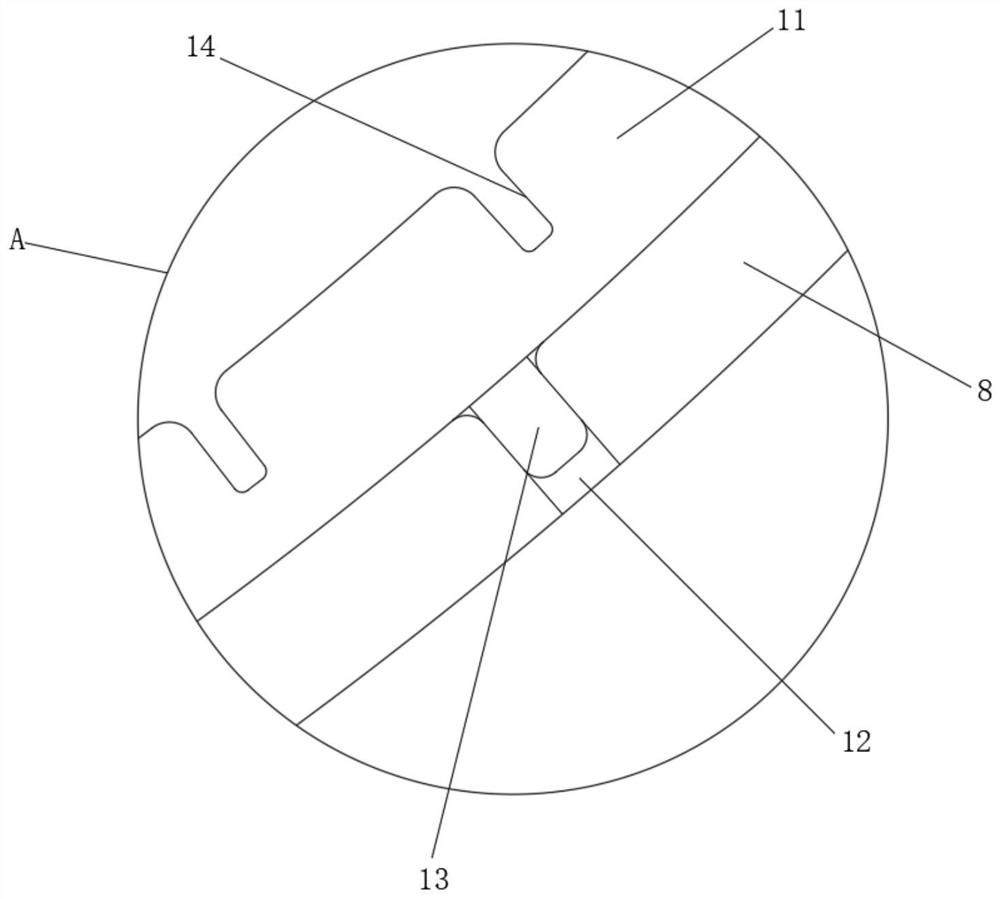

Multi-modal marine environment data fusion acquisition system and method

ActiveCN110674245AImprove collection efficiencyIncrease transfer rateMetadata text retrievalData processing applicationsData acquisitionEngineering

The invention relates to a multi-modal marine environment data fusion acquisition system and method. The multi-modal marine environment data fusion acquisition system comprises a plurality of marine environment data acquisition stations, an unmanned ship and a data statistics server, wherein the marine environment data acquisition stations are distributed at marine data acquisition points, and thedata statistics server stores acquisition positions of the marine data acquisition points and ID numbers of the corresponding marine environment acquisition stations; the marine environment acquisition station comprises a camera, a voice input device, a text input device, a display screen, an acquisition station controller and a first data storage device; the camera is arranged on a rotating support, and the rotating support drives the camera to continuously rotate according to a preset rotating speed, and the camera collects video data, and the voice input device is used for collecting voicedata of a user; and the text input device is used for collecting text data of the user. The invention provides a multi-modal data acquisition form, capable of improving the data acquisition efficiency, and being richer in the acquired data types.

Owner:ZHOUSHAN OCEAN UNIV SCI & TECH RES INST CO LTD

High-emission vehicle comprehensive integrated monitoring Internet of Things device

PendingCN113612826AFully contactedThe test result is accurateVehicle componentsParticle suspension analysisGas collecting tubeIntegrated monitoring

The invention provides a high-emission vehicle comprehensive integrated monitoring Internet of Things device which comprises a detection probe (3), a control assembly (2) and a connecting pipe (1), wherein the detection probe (3) and the control assembly (2) are arranged at the two ends of the connecting pipe (1) respectively; at least one detection ring (4) is arranged on the outer surface of the detection probe (3); each detection ring (4) is arranged in an inner cavity of a gas collecting tube (5); a gas inlet and a gas outlet of the gas collecting tube (5) are arranged along the length direction of the detection probe (3); and the size of the gas inlet of the gas collecting tube (5) is larger than that of the gas outlet of the gas collecting tube (5). According to the invention, it can be ensured that the collected automobile exhaust fully contacts the detection ring (4) after being converged in the gas collecting pipe (5), so that the detection result is more accurate.

Owner:BEIJING UNION UNIVERSITY

Method for Rapidly Constructing Cardiac Coronary Vessel Identification Dataset

ActiveCN109063557BBig amount of dataReal dataNeural architecturesPhysiological signal biometric patternsData setRadiology

The present invention provides a method for quickly constructing a heart coronary vessel recognition data set, comprising: obtaining an original picture; marking blood vessels in the original picture to form a rough-labeled picture; performing pixel-level labeling on a very small amount of original pictures according to the rough-labeled picture. Form a finely labeled picture; change the finely labeled picture from a three-channel image to a single-channel image; binarize the single-channel image and store it as a binarized picture; use the binarized picture and its corresponding original picture as training data, Train the initial network to obtain the first network; input all the original pictures into the above-mentioned first network to obtain the binarized result map; generate pseudo-fine annotations based on the binarized result map and its corresponding rough-labeled pictures Pictures: Create a data set based on original pictures, finely labeled pictures, and pseudo-finely labeled pictures to train the network. This method greatly reduces the cost of manual labeling while ensuring the quality of the data set, and the training speed can be significantly improved.

Owner:北京红云智胜科技有限公司 +1

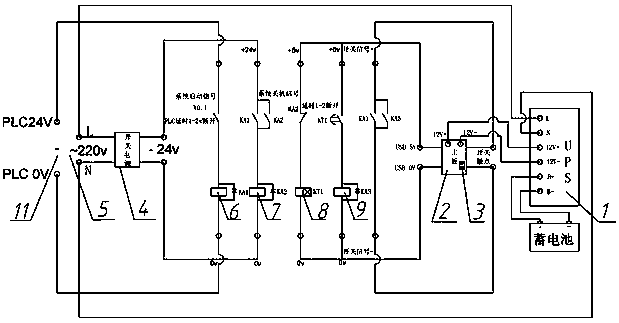

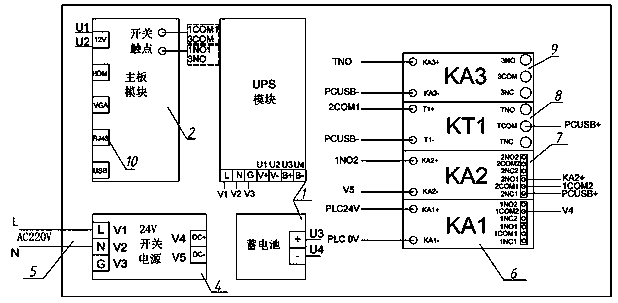

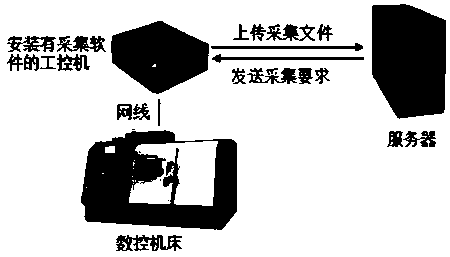

Numerical control machine tool operating data collecting terminal having mobile communication capability and supporting data customization

ActiveCN109032067AFirmly connectedRich data typesProgramme controlComputer controlNumerical controlData acquisition

A numerical control machine tool operating data collecting terminal having mobile communication capability and supporting data customization contains a UPS module, a mainboard, a 4G communication module, a switching power supply, an AC 220V plug, a 24V relay KA1, a 24V relay KA2, a 5V delay module KT1, a 5V relay KA3, an RJ45 interface and a PLC 24V power supply signal interface terminal row. After receiving a power-on signal of a PLC of a numerical control machine tool to be started, the collecting terminal is connected with the machine tool through the RJ45 interface (internet access) and connected with a server through the 4G communication module, and if connection is interrupted, the collecting terminal is continuously reconnected with the machine tool and the server to ensure normal communication with the machine tool and the server. After the collecting terminal, the machine tool and the server are in normal communication, collecting software automatically reads a pre-created machine tool identification file to communicate with the machine tool and identify basic information of the machine tool; and after the machine tool is identified, the collecting terminal parses a machine tool control file, collects information including the machining time, tool information, output statistics, alarming history, operation information, operation history, macro variables, PMC variablesand NC programs according to the requirements, and sends the information to the server.

Owner:SHANGHAI UNIV

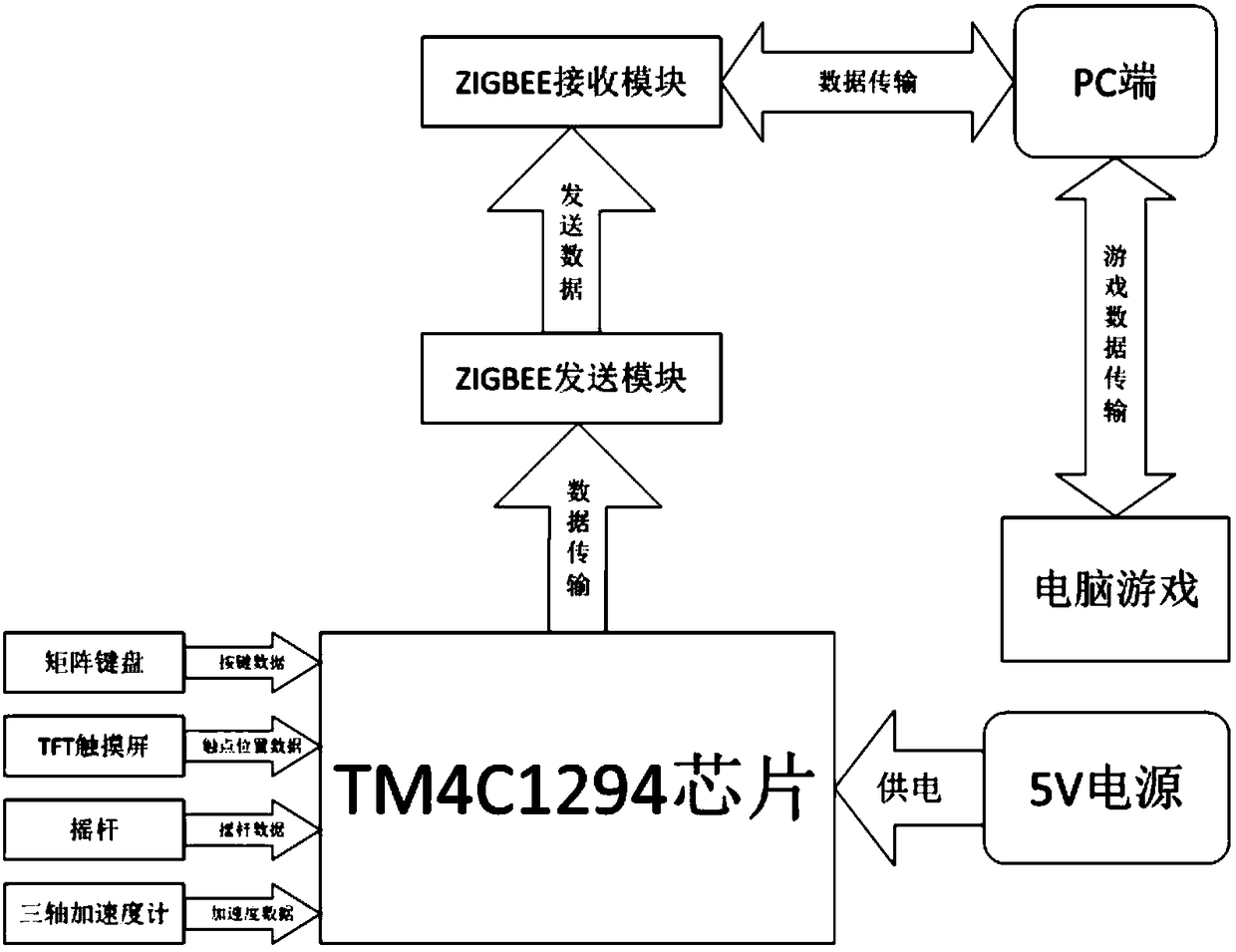

Multivariate data acquisition system based on embedded system

InactiveCN108829284ARich data typesImprove applicabilityInput/output for user-computer interactionTransmission systemsTriaxial accelerometerData acquisition

The invention relates to a multivariate data acquisition system based on an embedded system. The system comprises a control chip, a matrix keyboard, a TFT touch screen, a triaxial accelerometer, a rocker, a ZigBee sending module and a ZigBee receiving module; the matrix keyboard, the TFT touch screen, the triaxial accelerometer and the rocker are all connected with the control chip; the control chip is connected with the ZigBee sending module; the ZigBee sending module is in communication connection with the ZigBee receiving module; the ZigBee receiving module is connected with a PC end. The invention provides the multivariate data acquisition system based on the embedded system, which is rich in data type and good in applicability.

Owner:ZHEJIANG UNIV OF TECH

Wireless sensor node with functions of automatic program updating and parameter correcting

InactiveCN102547805AStrong real-timeRich data typesNetwork topologiesTransceiverWireless transceiver

The invention discloses a wireless sensor node with functions of automatic program updating and parameter correcting, which comprises a sensor module, a CPU (central processing unit) module, a short-distance wireless communication module, a data memory module, a wireless transceiver, a program loading and updating module, a parameter correcting module, an automatic information type identification module, an information transferring module and a power module. The short-distance wireless communication module is used for automatically searching adjacent wireless sensor nodes. The wireless transceiver is used for synchronously receiving control information consisting of parameter correction information and program updating information transmitted by an upper computer while uploading data acquired by the sensor module. The automatic information type identification module is used for automatically identifying and classifying control information types. The information transferring module is used for transferring the information classified by the automatic information type identification module to the program loading and updating module and the parameter correcting module respectively. The wireless sensor node is reasonable in design, convenient in networking and maintenance, convenient and effective in use, high in intelligent level and capable of automatically upgrading and updating internal programs and correcting operation parameters.

Owner:XIAN LIANYOU ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com