Fault prediction method and system for intelligent manufacturing equipment based on neural network model

A neural network model and equipment failure technology, applied in biological neural network models, manufacturing computing systems, predictions, etc., can solve problems such as prolonging equipment maintenance or replacement cycles, inability of production lines to produce effectively, and affecting the production efficiency of intelligent manufacturing production lines. Achieving low production loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

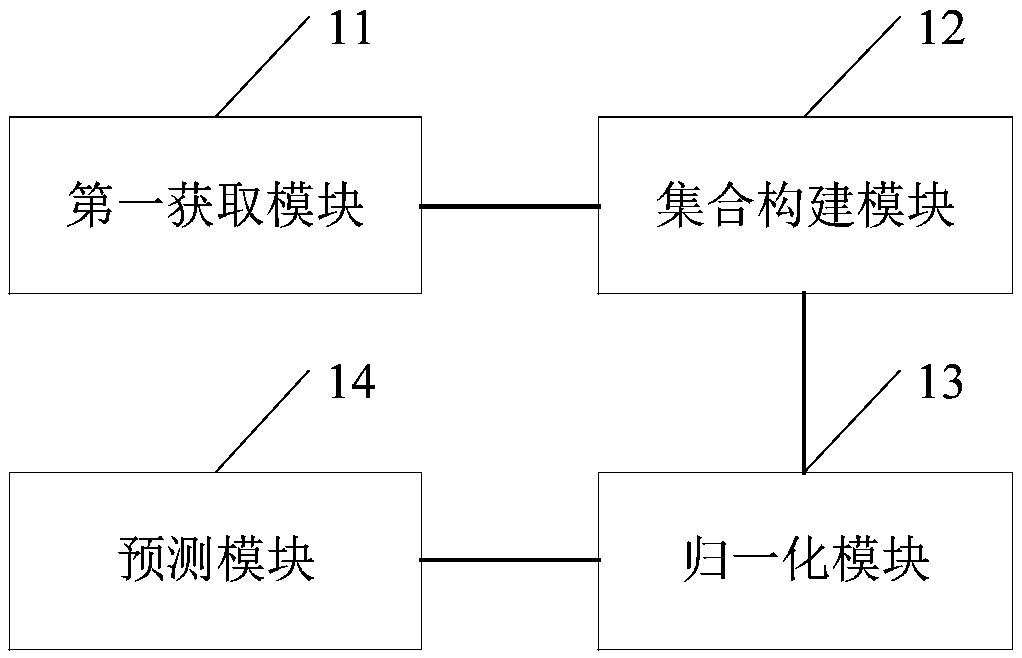

[0086] see image 3 , image 3 It is a schematic diagram of the structural composition of the intelligent manufacturing equipment fault prediction system based on the neural network model in the embodiment of the present invention.

[0087] Such as image 3 As shown, a device failure time prediction system on an intelligent manufacturing production line, the device failure prediction system includes:

[0088] The first acquiring module 11: used to acquire the parameter of the running time of the equipment, the average running load parameter of the running time and the average running time parameter of each day during the running time;

[0089]In the implementation process of the present invention, corresponding parameter collection is carried out by installing corresponding data parameter collectors or corresponding data parameter collection software on the equipment on the production line of intelligent manufacturing, such as installing running load parameter collection sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com