Method for judging nitrosation process of SBR process by liquid phase N2O concentration on-line detector

A nitrosation and detector technology, applied in the field of environmental engineering, can solve problems such as real-time control of N2O nitrosation process that is not mentioned, and achieve the effect of assisting process operating parameters and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

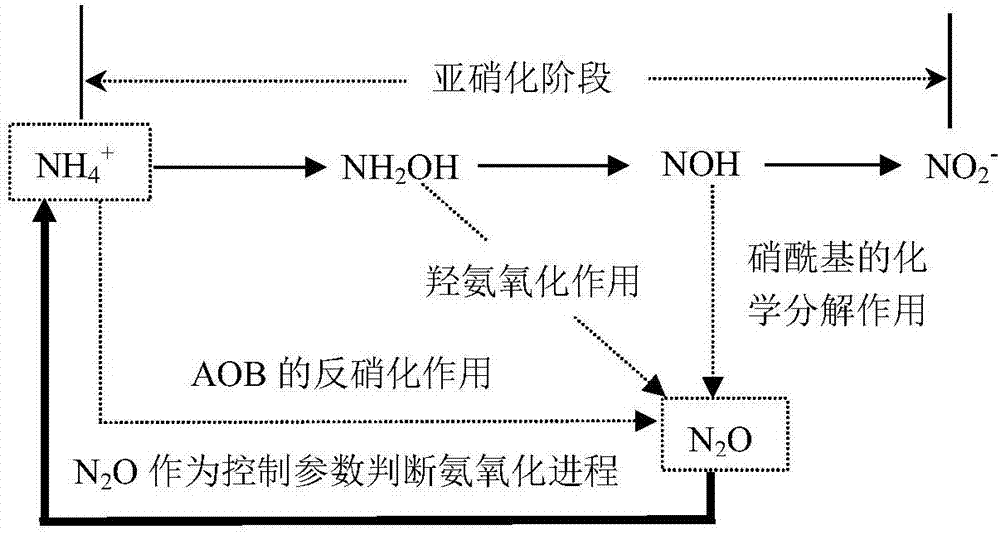

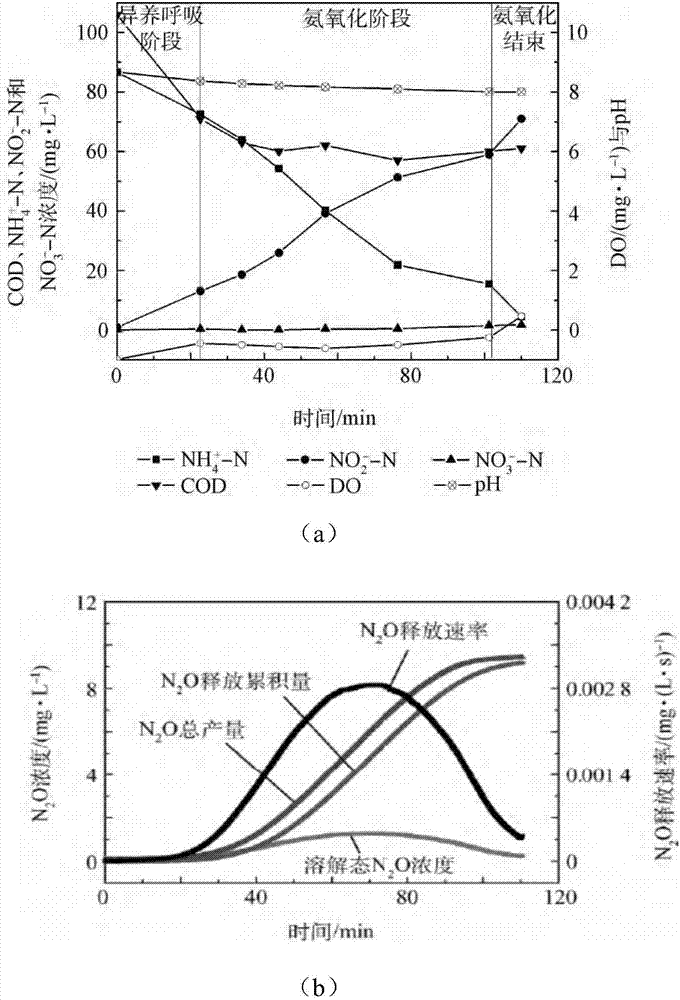

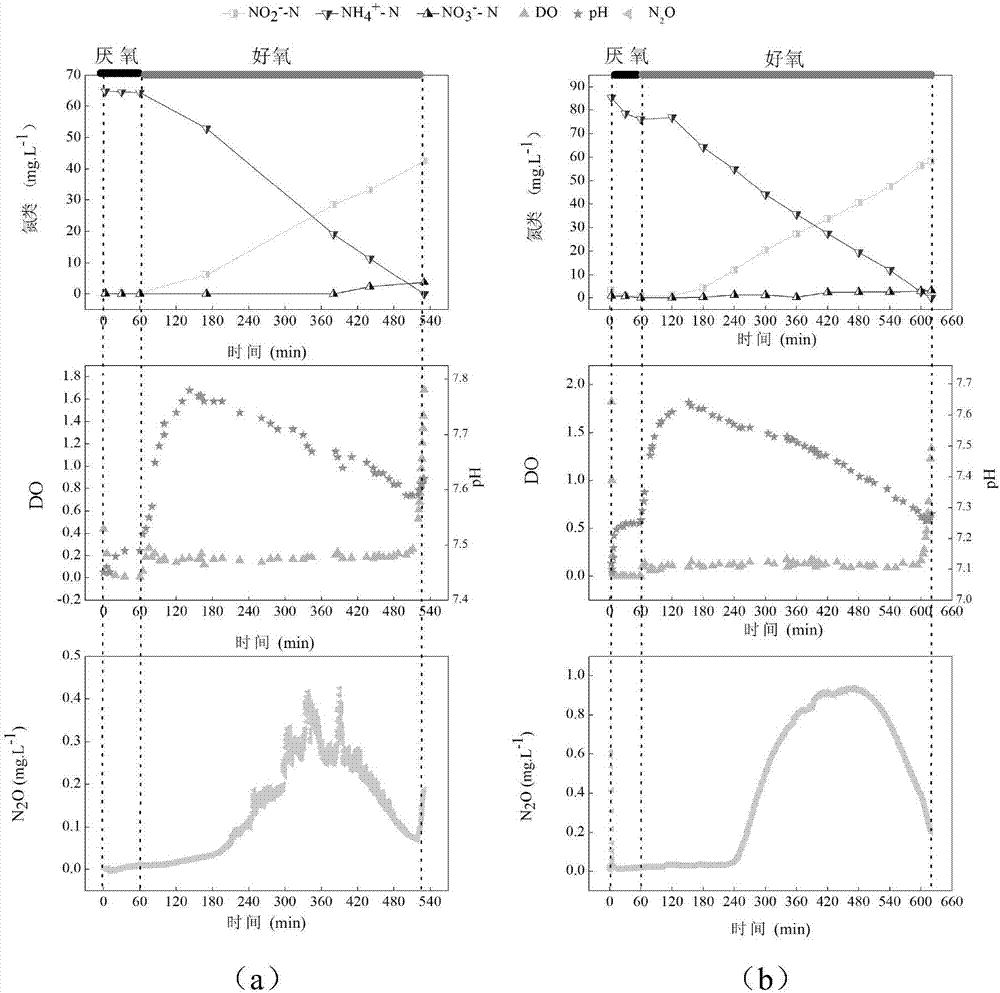

[0017] see figure 1 : The present invention adopts liquid phase N 2 The method for judging the nitrosation process of the SBR process by the O concentration online detector is to monitor the liquid phase N in the low-oxygen ammonium oxidation process online. 2 O concentration curve, according to the characteristics of the curve to judge the completion time of nitrosation reaction. Specifically: under aeration conditions, when N 2 The concentration of O rises first and then drops until it reaches the lowest point when it starts to rise, that is, this point is used as the judgment point for the completion of nitrosation (the time point when aeration is stopped). This point corresponds to the highest concentration of nitrite nitrogen in the solution, so as to realize the accumulation of nitrite nitrogen and the precise control of the SBR nitrosation process. If the aeration time is too long (continuing aeration beyond this point), it will lead to the conversion of nitrite nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com