Test device for chemical evaporation kinetics behavior

A test device and chemical technology, applied in the field of nuclear power plant safety, can solve problems such as the inability to simulate the on-site environment of the pressure test in the containment, and achieve the effects of true and reliable results, avoidance of fire risk loss, and accurate qualitative and quantitative analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

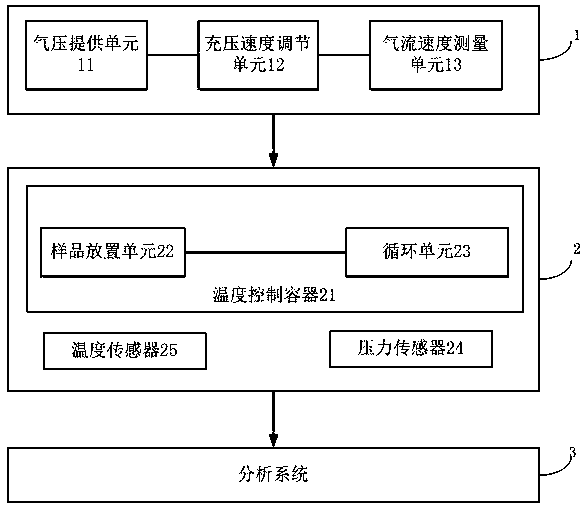

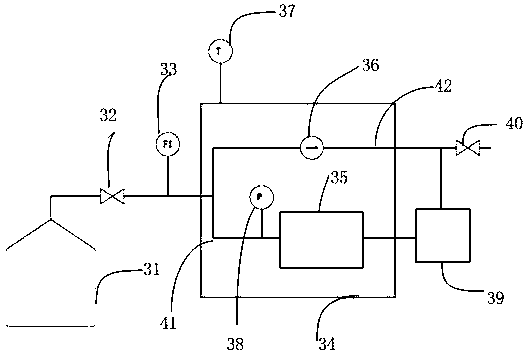

[0023] Such as figure 1 As shown, the test device for studying chemical volatilization dynamics behavior of the present invention includes a simulated pressure system 1, a chemical volatilization system 2 and an analysis system 3, wherein the simulated pressure system 1 is used to simulate the pressure conditions of the containment pressure test of a nuclear power plant. Chemical volatilization system 2 provides gas at a predetermined pressure; chemical volatilization system 2 is used to simulate chemical volatilization conditions in the containment under different gas pressures and flow rates; analysis system 3 is used to measure The type and related parameters of the gas volatilized by the chemical.

[0024] Wherein, the simulated pressing system 1 includes an air pressure supply unit 11, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com