Application of DC motor speed control system based on L298N in optical measurement

A DC motor and optical detection technology, applied in the direction of DC motor rotation control, excitation or armature current control, etc., can solve the problems of contact error and low efficiency, achieve accurate measurement results and realize the effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

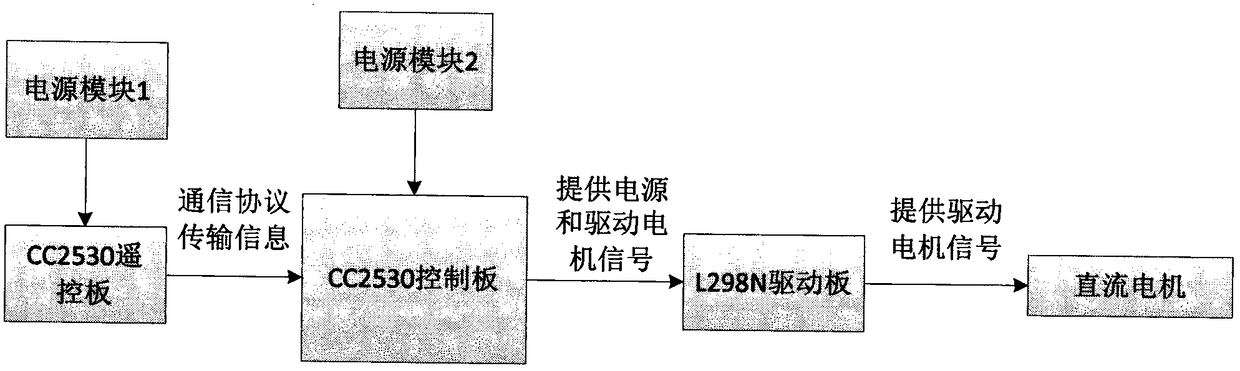

[0020] An embodiment of the present invention is a DC motor speed control system based on L298N, such as figure 1 As shown, the system is mainly composed of two parts, the sending module and the control module.

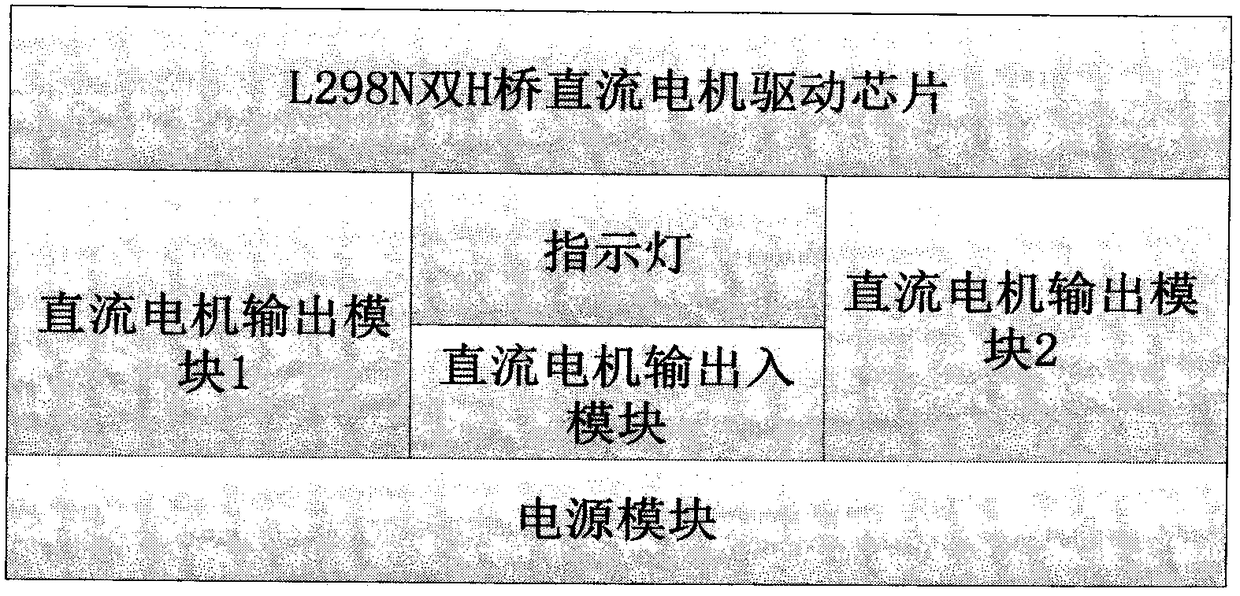

[0021] The control module is used to control the micro-adjustment of the measurement unit, mainly including the core processor, wireless module, motor drive unit and related peripheral devices.

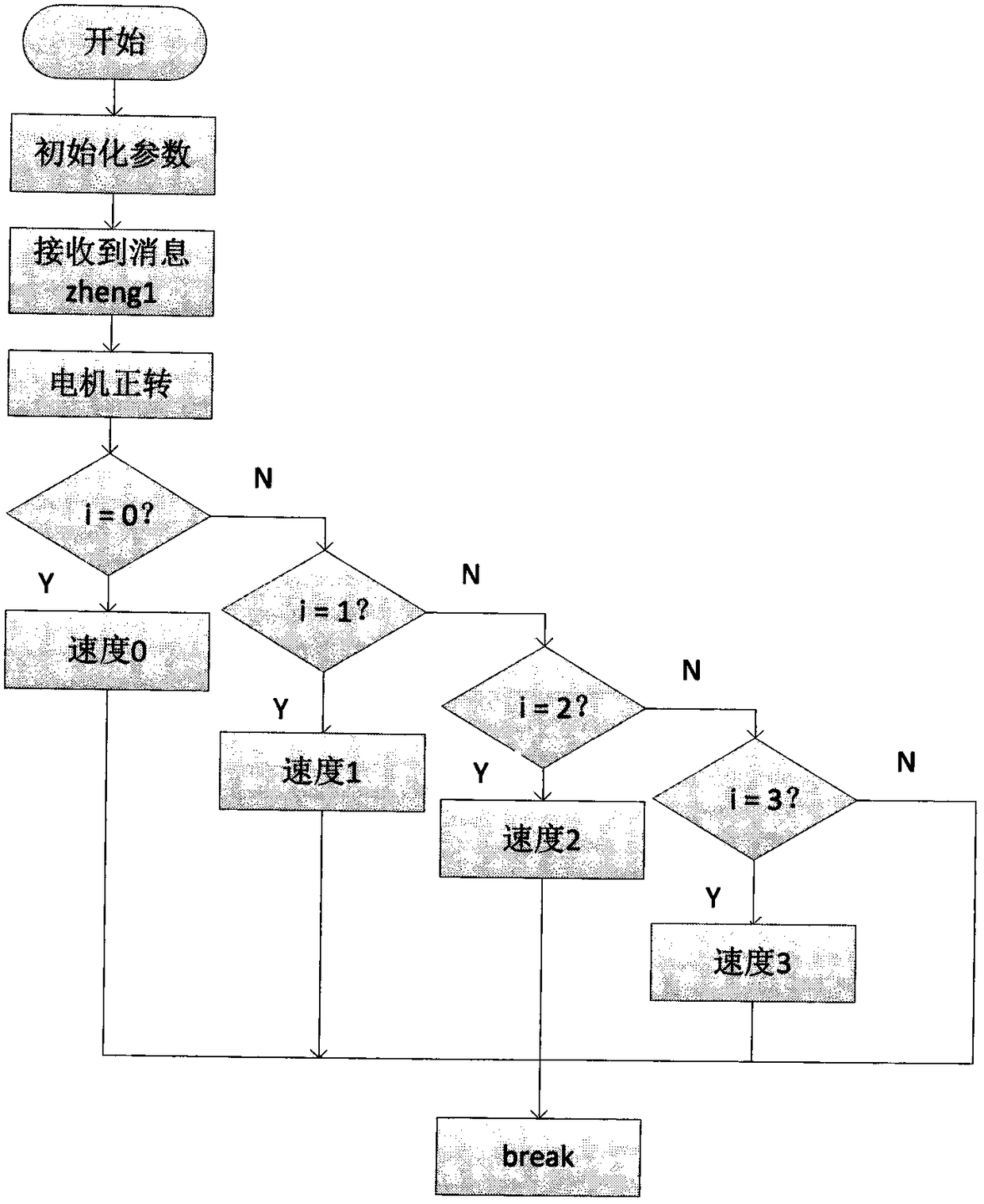

[0022] The processor can take corresponding control actions after receiving the signal sent by the sending module through the radio frequency module, and realize fine control of the optical adjustment components by controlling the rotation of the motor structure.

[0023] The remote control mainly sends command signals from the processor, and transmits them to the control module through the wireless module to control the forward and reverse rotation of the DC motor, thereby driving the adjustment of optical parameter conditions and adjusting the optical measurement parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com