Ultrasonic atomization cultivation box and method thereof for precise spraying of wrapped root system

A technology of ultrasonic atomization and cultivation box, which is applied in cultivation, soilless cultivation, botany equipment and methods, etc. It can solve the problems of low water and fertilizer utilization efficiency, high energy consumption, and damage to the chemical structure of nutrient solution, and achieves compact structure, The effect of small footprint and convenient experimental research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

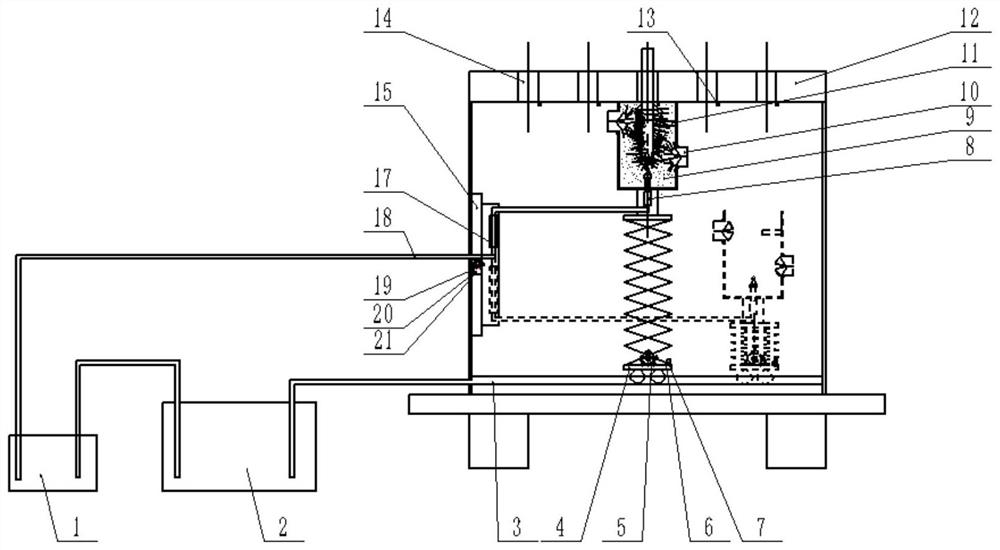

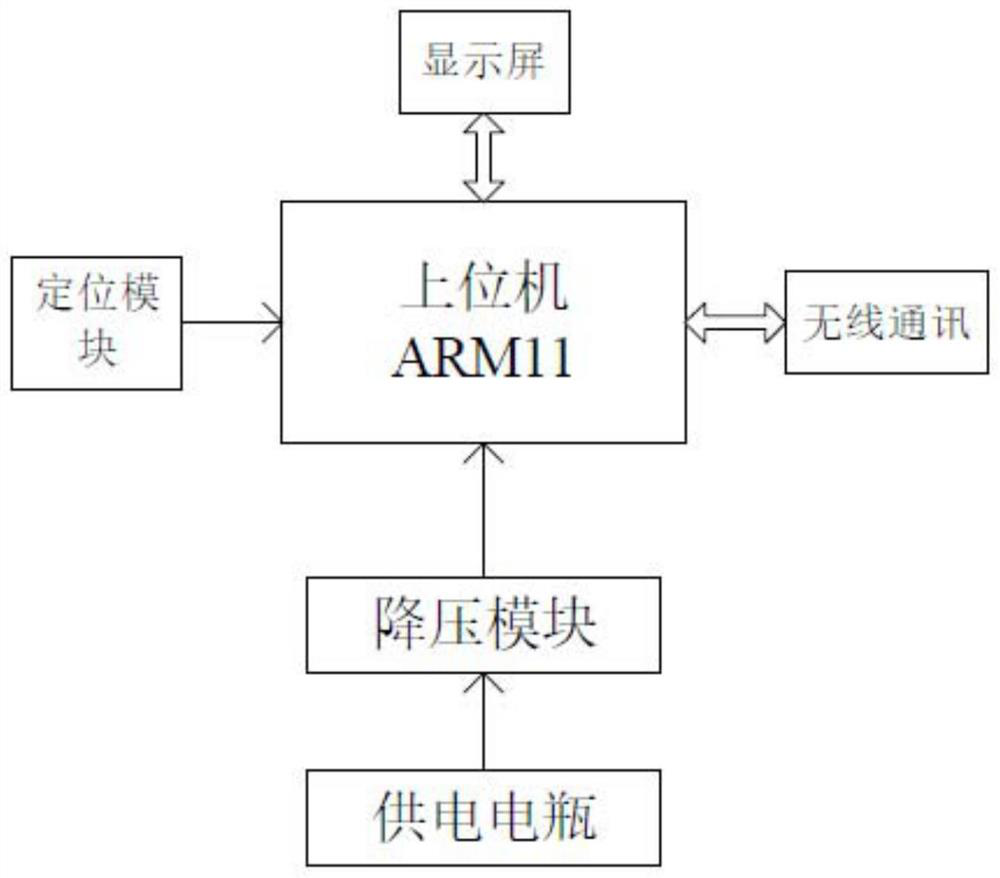

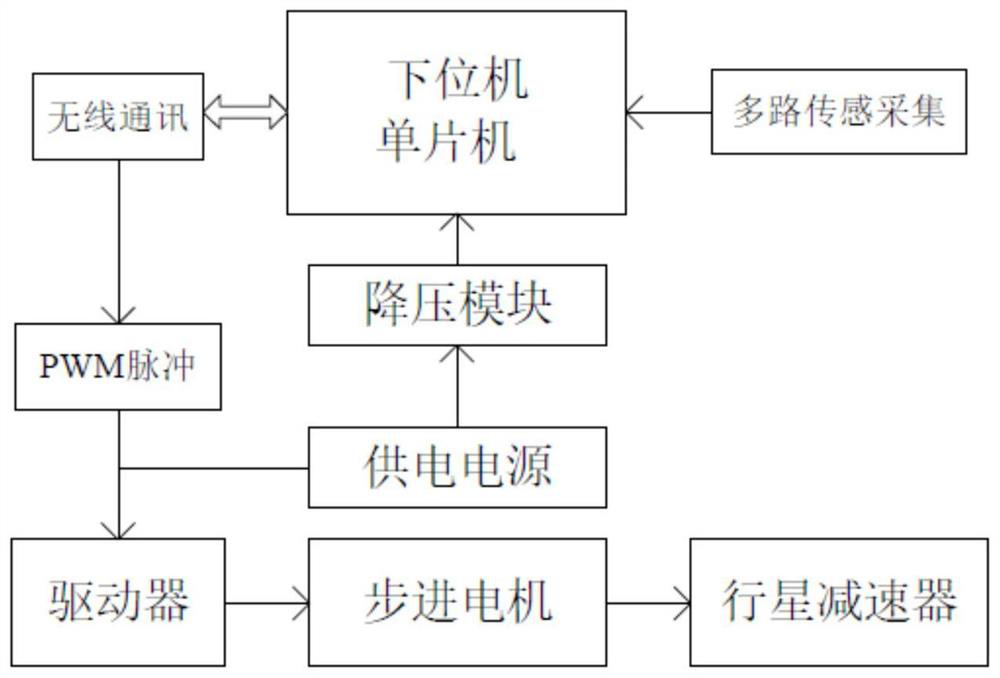

[0032] attached figure 1 It is an ultrasonic atomization cultivation box for precise spraying of root systems involved in the present invention. The information collection module includes a temperature and humidity sensor 11 and a position sensor 13; it is used to collect the position and humidity information of the roots, and the collected information is transmitted via wireless Transmitted to the first controller 7; the job execution module includes the atomization chamber 9, the lifting platform 4 and the rotating platform 15; the lifting platform 4 and the rotating platform 15 are respectively controlled by the first stepping motor 5 and the second stepping motor 19 control; the first stepping motor 5, the second stepping motor 19 are controlled by the first wireless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com