Metal oxide/HTS-1 titanium silicalite molecular sieve catalyst and preparation method and application thereof

A titanium-silicon molecular sieve and catalyst technology, which is applied in the field of metal oxide/HST-1 titanium-silicon molecular sieve and its preparation, can solve the problems of short service life, unstable performance, low catalyst activity, etc., so as to improve the activity and service life, Good void ratio and specific surface area, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

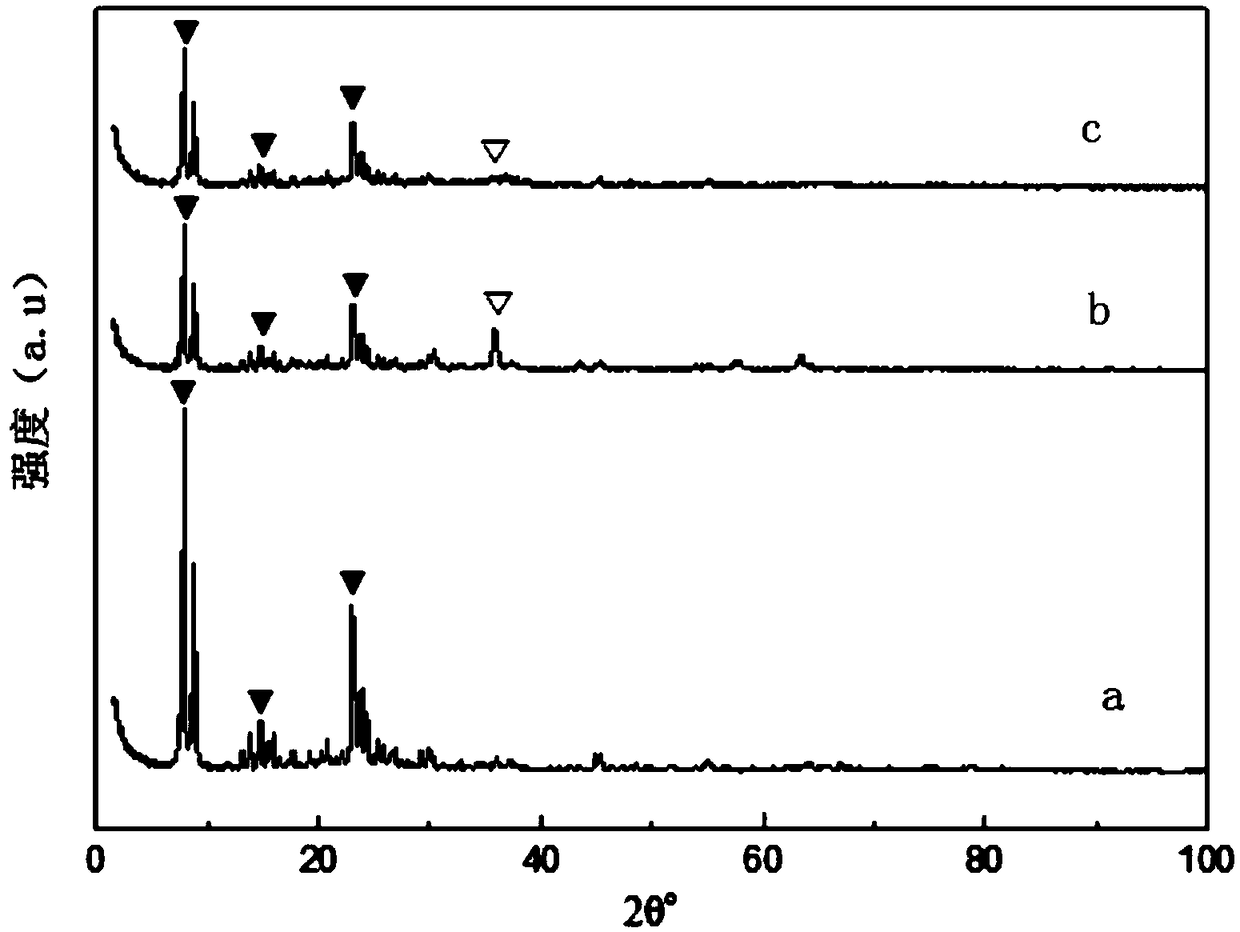

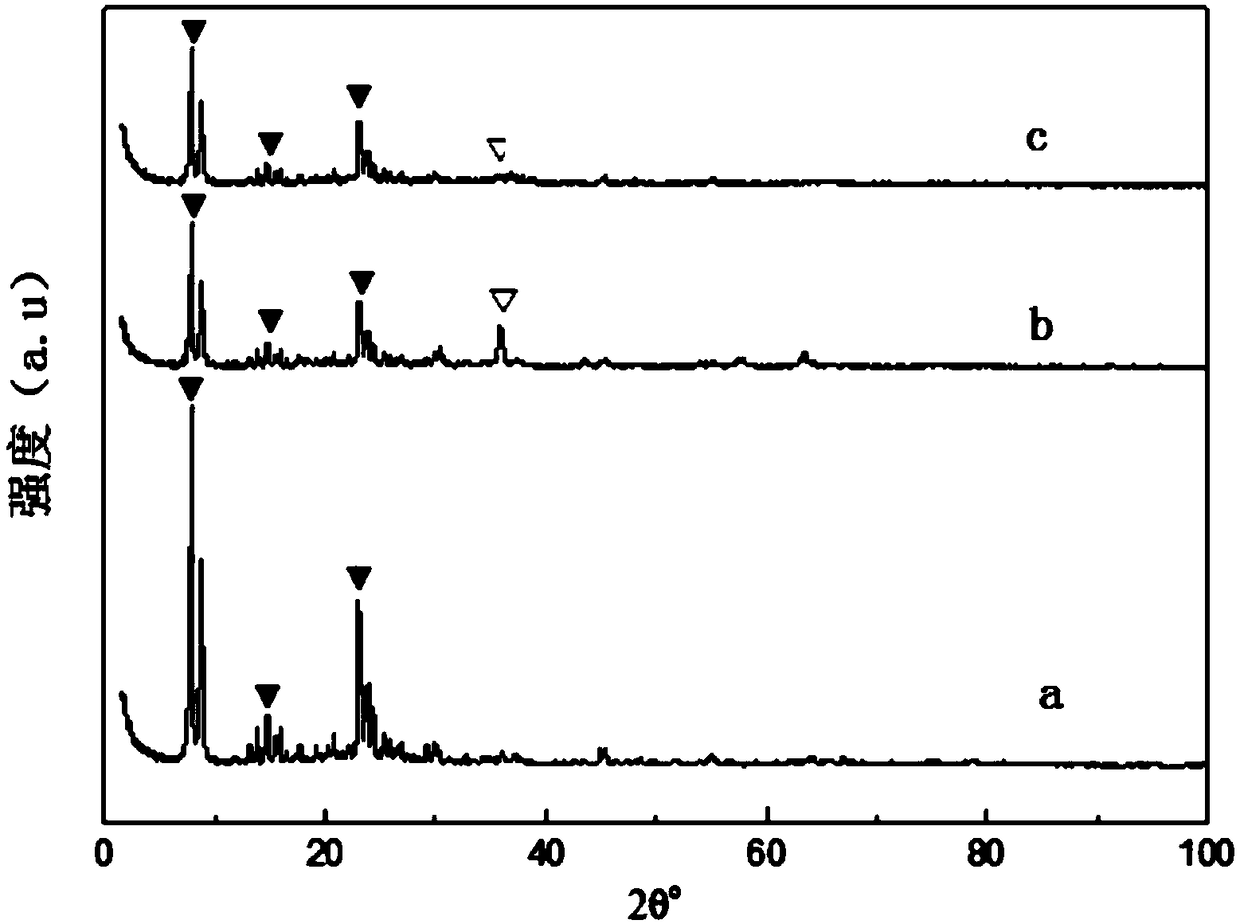

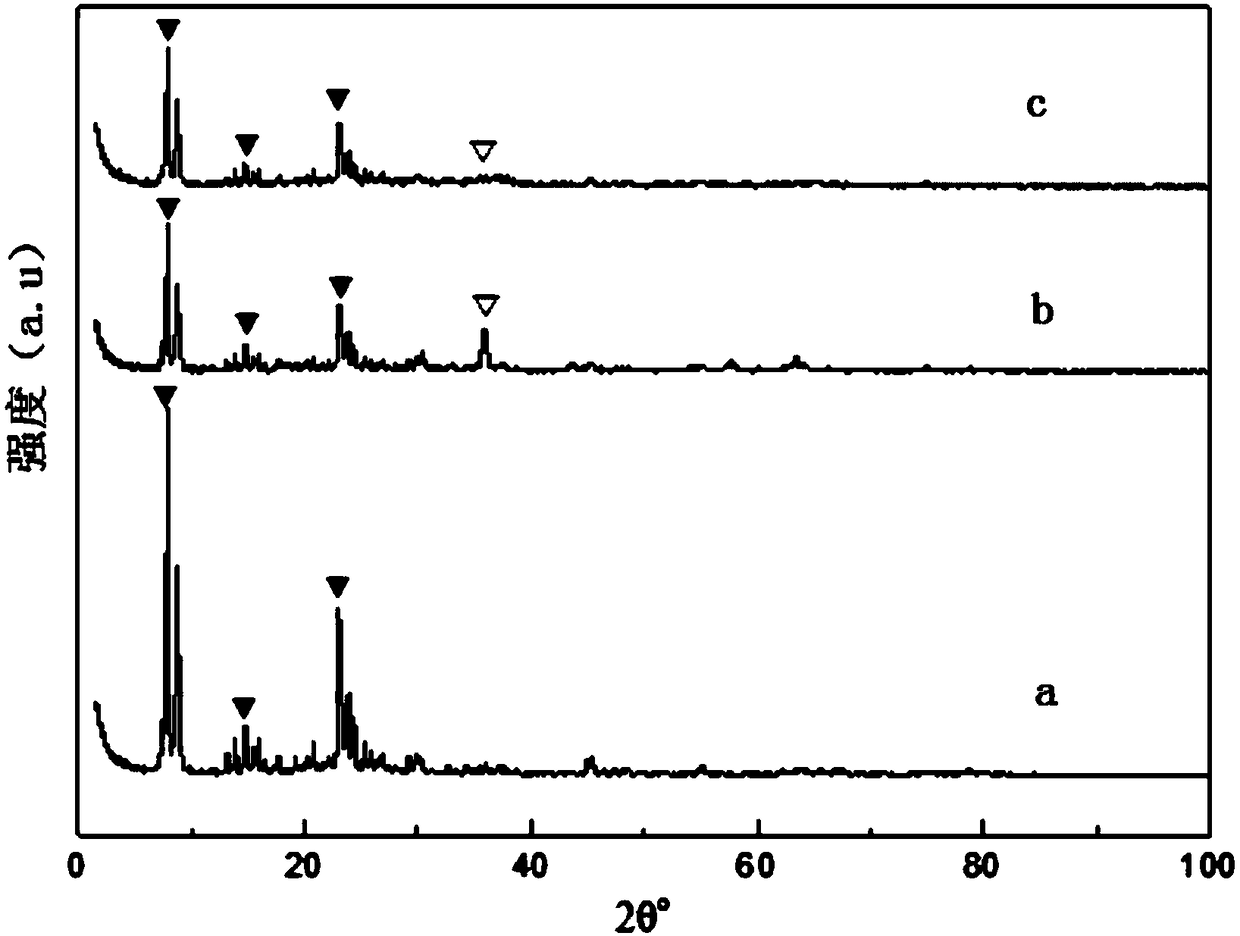

Image

Examples

Embodiment 1

[0042] A kind of preparation method of metal oxide / HTS-1 titanium silicon molecular sieve catalyst:

[0043] Step 1, by molar ratio Cu:Mn:Nd=0.9:2:0.1, Mn 2+ Concentration is 1.4mol / L as the benchmark, weigh Cu(NO 3 ) 2 ·3H 2 O (99.5%) 15.2973g, Mn (NO 3 ) 2 (50%w / w) 50.1060g, Nd(NO 3 ) 3 ·6H 2 O (99%) 3.0995g, join in the beaker that fills 100mL distilled water, obtain metal nitrate solution;

[0044] Step 2. Immerse 2.1 g of HTS-1 titanium-silicon molecular sieves in the metal nitrate solution, rotate at 50 r / min, stir at a constant temperature of 35°C for 24 hours, and alternately wash and filter the impregnated solid-liquid mixture with ethanol and deionized water for 2 ~3 times, put the obtained solid into a blast drying oven, dry at 60°C for 300min, grind the obtained solid into powder, heat up to 550°C for 180min in a muffle furnace at a heating rate of 3°C / min, and then cool down naturally. get the primary catalyst;

[0045] Step 3, place the primary catalyst...

Embodiment 2

[0051] A kind of preparation method of metal oxide / HTS-1 titanium silicon molecular sieve catalyst:

[0052] Step 1, by molar ratio Cu:Mn:Nd=0.8:2:0.2, Mn 2+ Concentration is 1.4mol / L as a benchmark, weigh Cu(NO 3 ) 2 ·3H 2 O (99.5%) 13.5976g, Mn (NO 3 ) 2 (50%w / w) 50.1060g, Nd(NO 3 ) 3 ·6H 2 O (99%) 6.1990g joins in the beaker of 100mL distilled water, obtains metal nitrate solution;

[0053] Step 2. Immerse 2.1 g of HTS-1 titanium-silicon molecular sieves in the metal nitrate solution at a speed of 50 r / min, and stir at a constant temperature of 35°C for 1080 min. Alternately wash and filter the impregnated solid-liquid mixture with ethanol and deionized water 2 ~ 3 times, the obtained solid was put into a blast drying oven, dried at 60°C for 500min, the obtained solid was ground into powder, roasted for 180min at a heating rate of 4°C / min at 540°C in a muffle furnace, and cooled naturally to obtain primary catalyst;

[0054] Step 3. Place the primary catalyst in t...

Embodiment 3

[0060] A kind of preparation method of metal oxide / HTS-1 titanium silicon molecular sieve catalyst:

[0061] Step 1, by molar ratio Cu:Mn:Sm=0.7:2:0.3, Mn 2+ Concentration is 1.4mol / L as a benchmark, weigh Cu(NO 3 ) 2 ·3H 2 O (99.5%) 11.8979g, Mn (NO 3 ) 2 (50%w / w) 50.1060g, Sm(NO 3 ) 3 (99%) 7.1351g, join in the beaker of 100mL distilled water, obtain metal nitrate solution;

[0062] Step 2. Immerse 2.1 g of HTS-1 titanium-silicon molecular sieves in the metal nitrate solution, rotate at 50 r / min, stir at a constant temperature of 35°C for 1200 min, and alternately wash and filter the impregnated solid-liquid mixture with ethanol and deionized water for 2 ~3 times, put the obtained solid into a blast drying oven, dry at 60°C for 400 minutes, grind the obtained solid into powder in a muffle furnace at a heating rate of 3°C / min at 550°C, roast for 3 hours, and naturally cool down to obtain primary catalyst;

[0063] Step 3. Place the primary catalyst in the metal nitra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com