Mechanical active suspension system

An active suspension, mechanical technology, applied in the field of vehicle suspension system, can solve the problems of high price, insufficient performance and high maintenance cost of active suspension system, achieve good self-locking characteristics, low manufacturing cost and large lifting range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

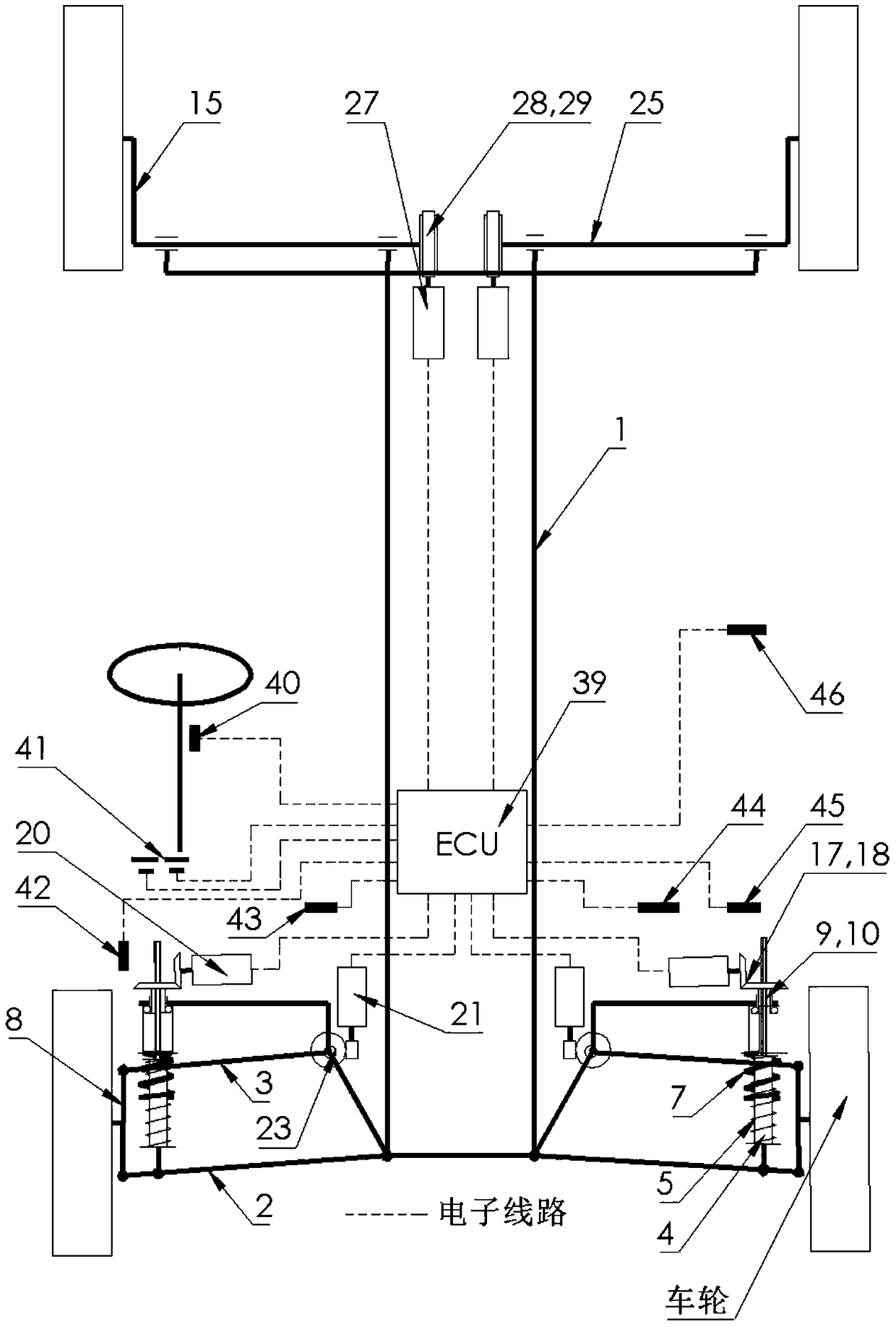

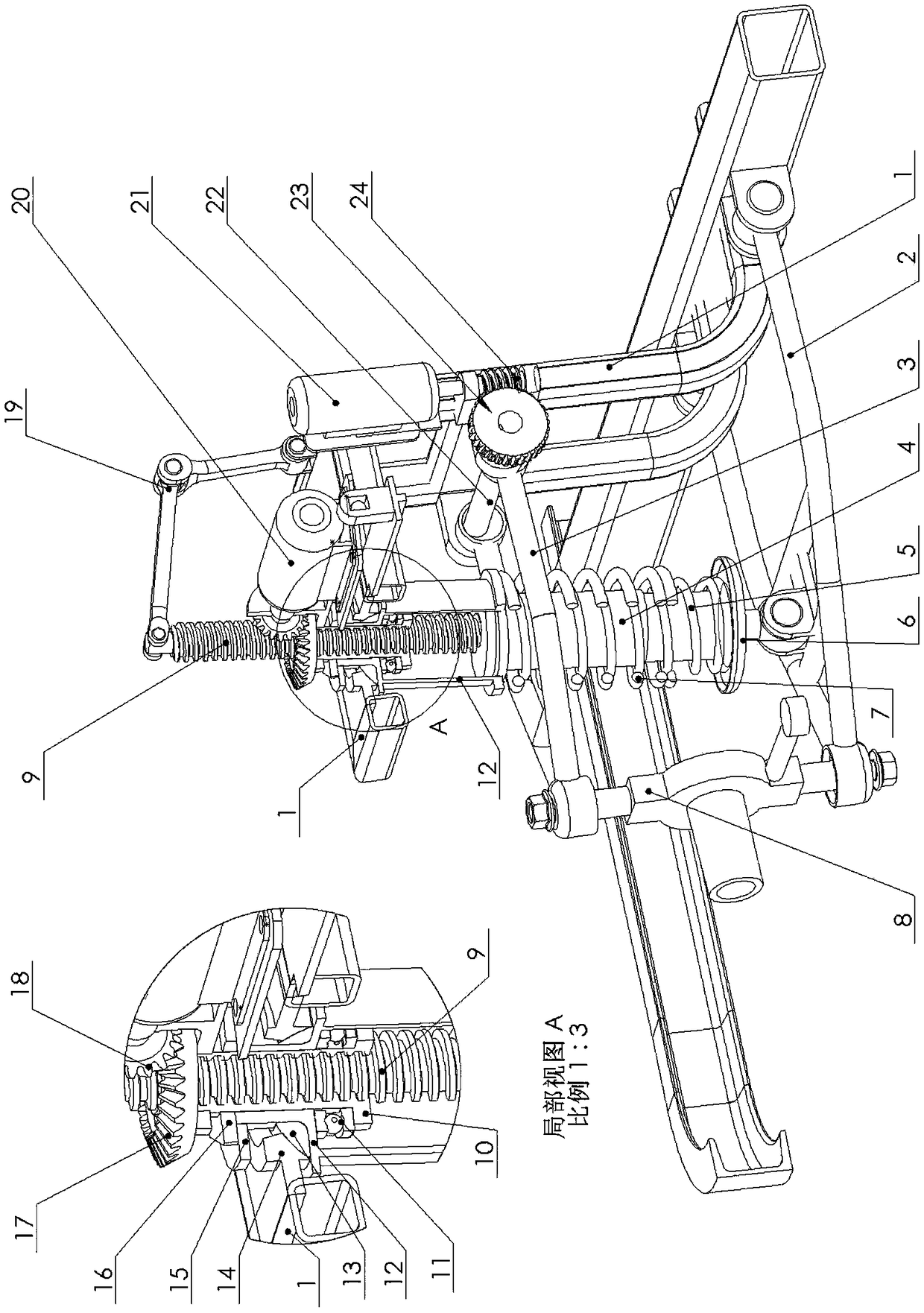

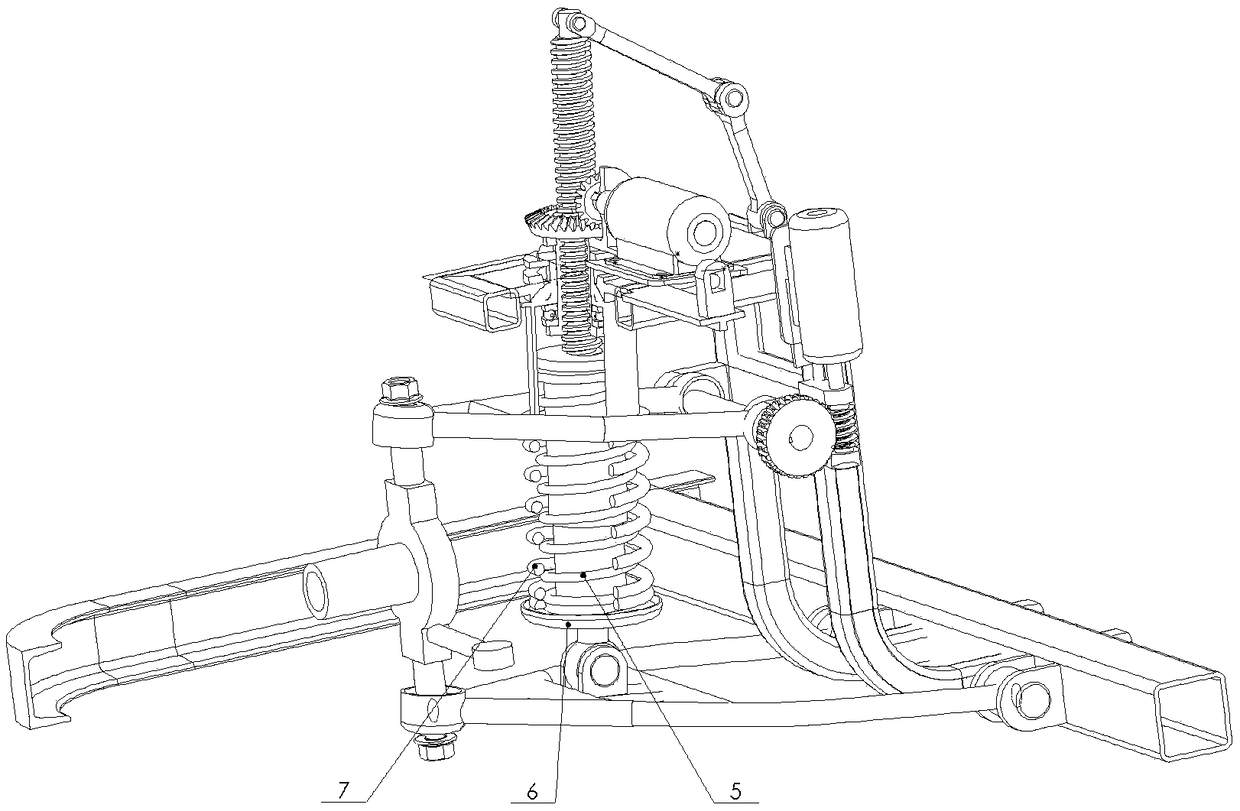

[0028] Hereinafter, exemplary embodiments of the present invention will be described with reference to the drawings. Throughout the specification, the same reference numbers represent the same parts, and the same parts in the left-right symmetrical mechanism will omit repeated reference numbers and descriptions. The accompanying drawings are only for better describing the concept of the present invention, and the understanding of the concept of the present invention is not limited to the accompanying drawings.

[0029] 1. The height adjustment of the suspension.

[0030] Such as figure 1 , figure 2 As shown, figure 2 It is an embodiment of unequal-length double wishbone front suspension. The lower cross arm 2, the upper cross arm 3 and the bogie 8 constitute a double wishbone suspension mechanism. The upper end of the main spring 5 and the shock absorber 4 are connected in series with the screw rod 9, and the lower end of the shock absorber 4 adopts a pin shaft and The lower cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com