A multi-rotor upright vehicle

An aircraft and multi-rotor technology, applied in the field of aircraft, can solve the problems of small load, high maintenance cost, and easy loss of control, and achieve the effects of reducing the speed of descent, improving wind resistance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

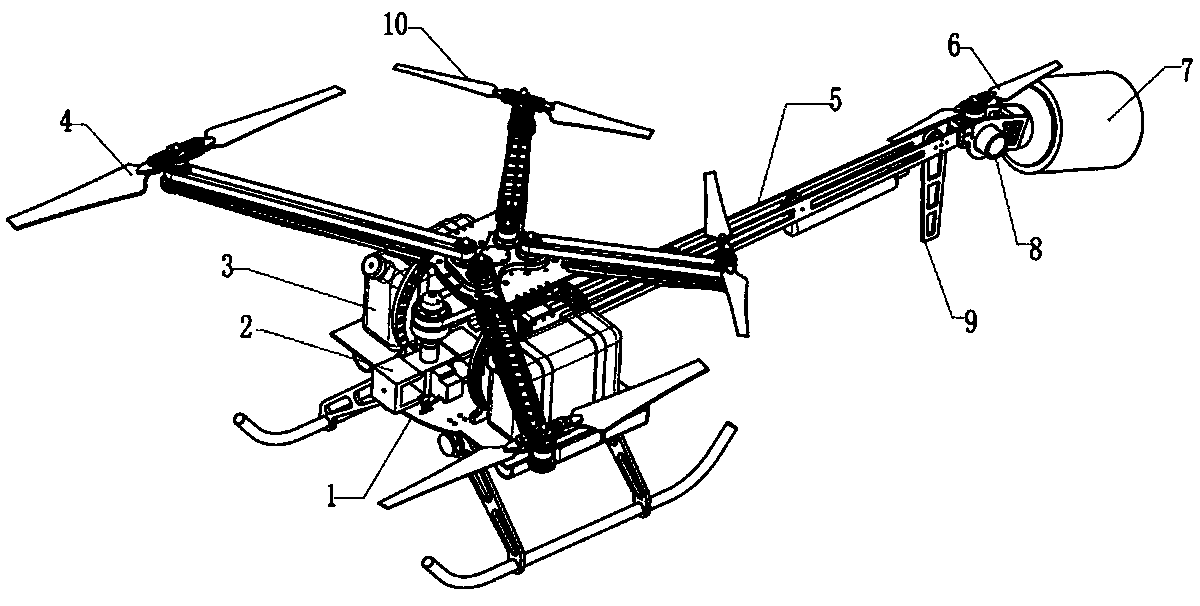

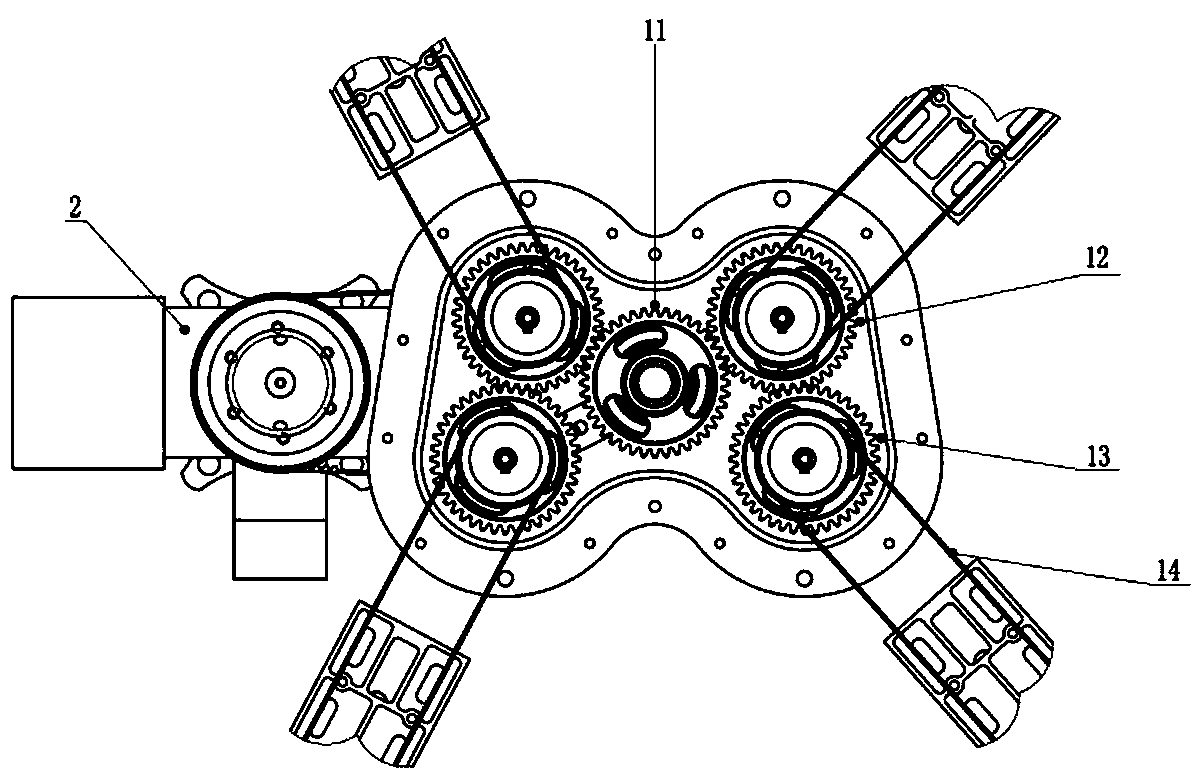

[0027] As shown in the figure, the present invention is a multi-rotor helicopter. , comprising a frame 1, a driving device, a transmission mechanism, a rotor bracket, a plurality of rotors, an empennage 5, a synchronizer, a protection device 7, a direction control device and a controller, the rotor bracket is arranged on the frame 1, and the plurality of rotors Set on the rotor bracket, the empennage 5 is connected with the frame 1; the driving device, controller and synchronizer are all arranged in the frame 1, the synchronizer is connected with the driving device, and the synchronizer is connected with multiple The branch rotors are connected; the empennage 5 is provided with a direction control device and a protection device 7; the controller is connected with the drive device and the protection device 7 respectively, and a synchronizer is used to control the drive device to drive the multi-rotors to rotate, so that the symmetrical rotors have the same The rotating speed an...

Embodiment 2

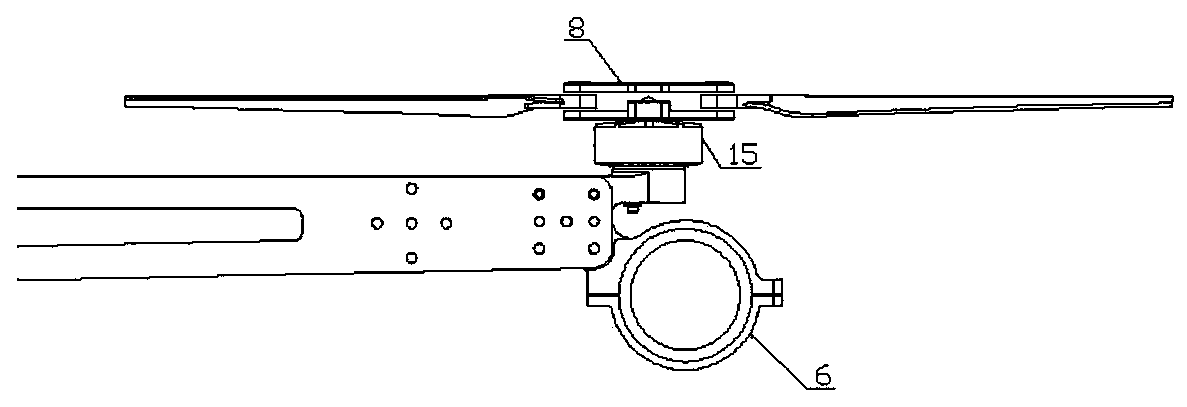

[0037] This embodiment is basically the same as Embodiment 1, the difference is that the direction control device also includes motors 15 arranged symmetrically up and down, and the motors 15 are respectively connected with propellers 6, and the central axes of the propellers 6 are all located on the same vertical plane. Inside. One of the motors 15 is forward rotation, and the other is reverse rotation. The two propellers 6 of the guiding device have a speed difference when they rotate. When controlling the guiding like this, compared with embodiment 1, the safety can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com