A container automatic loading and unloading machine

An automatic loading and unloading and container technology, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of high labor intensity, low efficiency, and long time, and achieve the effect of high precision, high efficiency, and fast steering speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

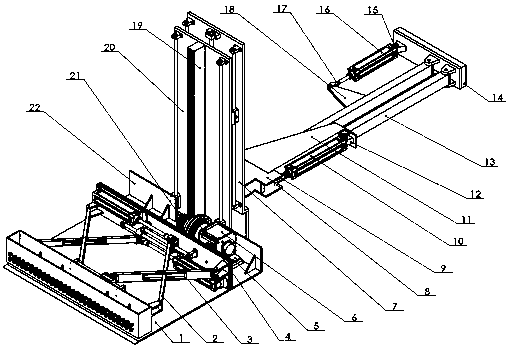

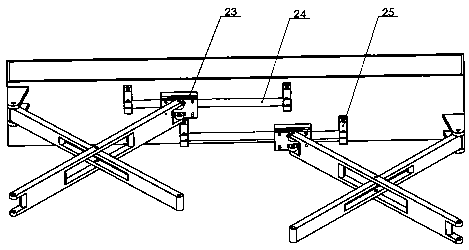

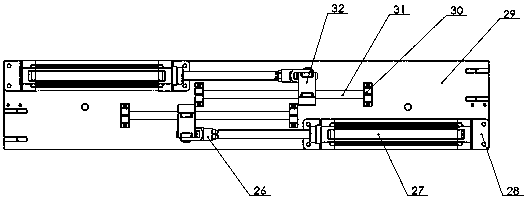

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 As shown, an automatic container loading and unloading machine is characterized in that it includes a shovel pallet 1, an inner link 2, an outer link 3, an RV reducer 4, a servo motor support base 5, a servo motor 6, a support plate A 7, Steering plate 8, rear cylinder L joint 9, rear cylinder L 10, rear cylinder L support plate 11, rear cylinder L support 12, steering link 13, fixed plate 14, rear cylinder R support 15, rear cylinder R 16, Rear cylinder R joint 17, support rib 18, rack 19, support plate B 20, gear 21, connecting plate 22, front linear bearing 23, front light bar A 24, front light bar support A 25, front cylinder joint 26 , Front cylinder 27, front cylinder support 28, support plate C 29, front light bar support B 30, front light bar B 31, three-phase joint 32, bull's eye bearing 33, vacuum suction cup 34, front plate 35, stepping Motor 36, stepping motor support seat 37, couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com