Winding device of glass fiber felt production line

A technology of glass fiber mat and winding device, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc., and can solve the problems of unsatisfactory low cost, rapid quantitative production, slow manual replacement, and many human resources. , to achieve the effect of reducing manpower input, avoiding uneven winding and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation of the present invention will be further described below in conjunction with the examples.

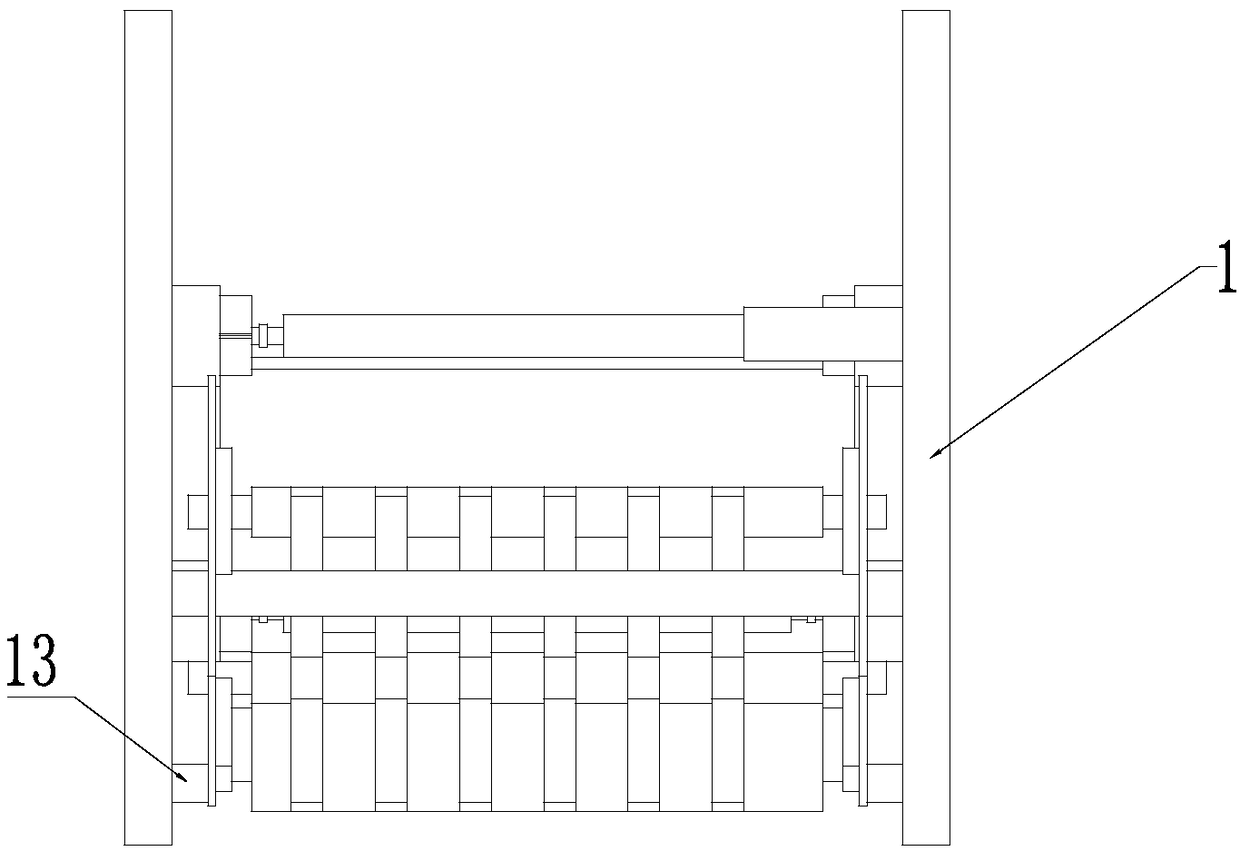

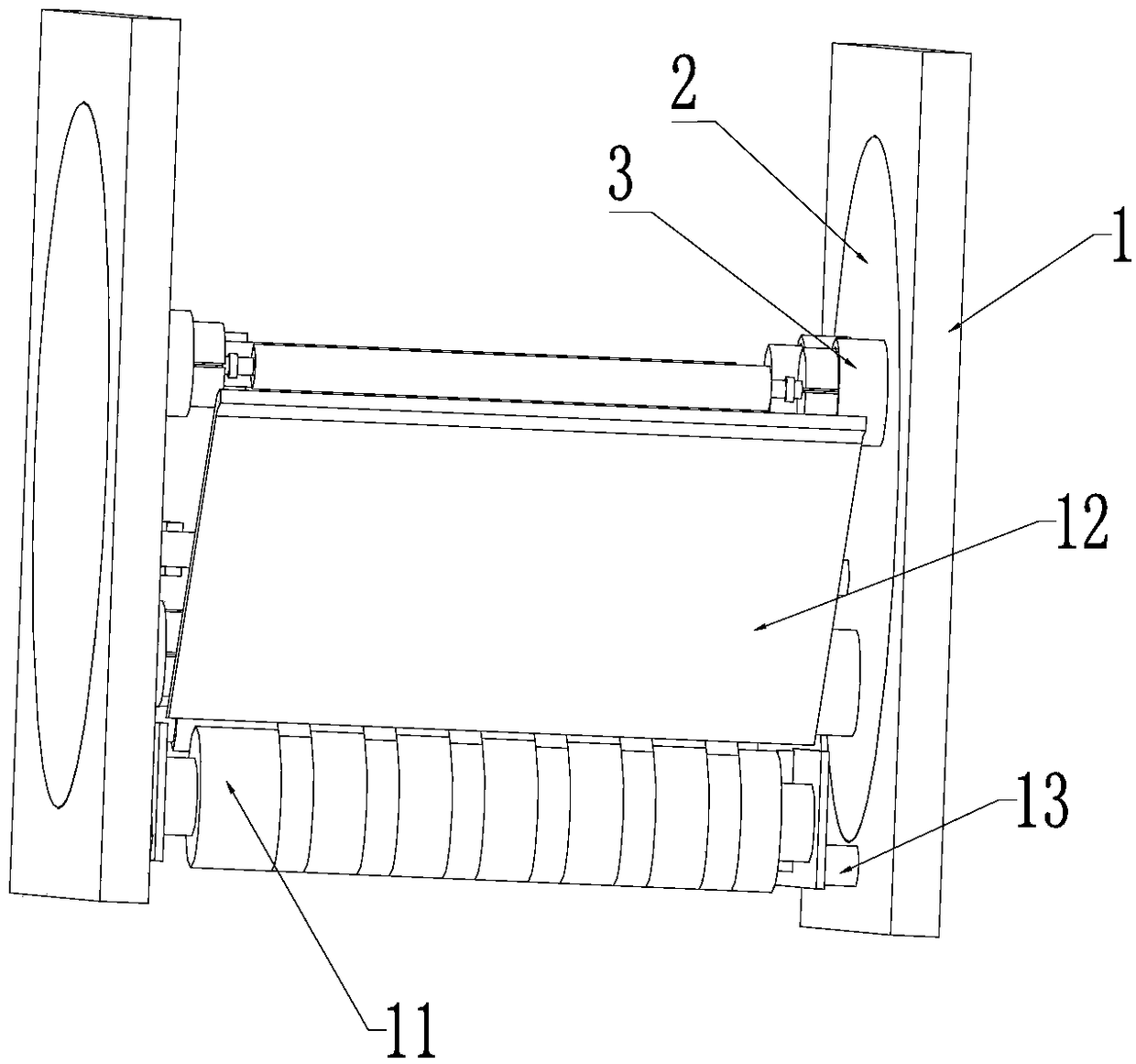

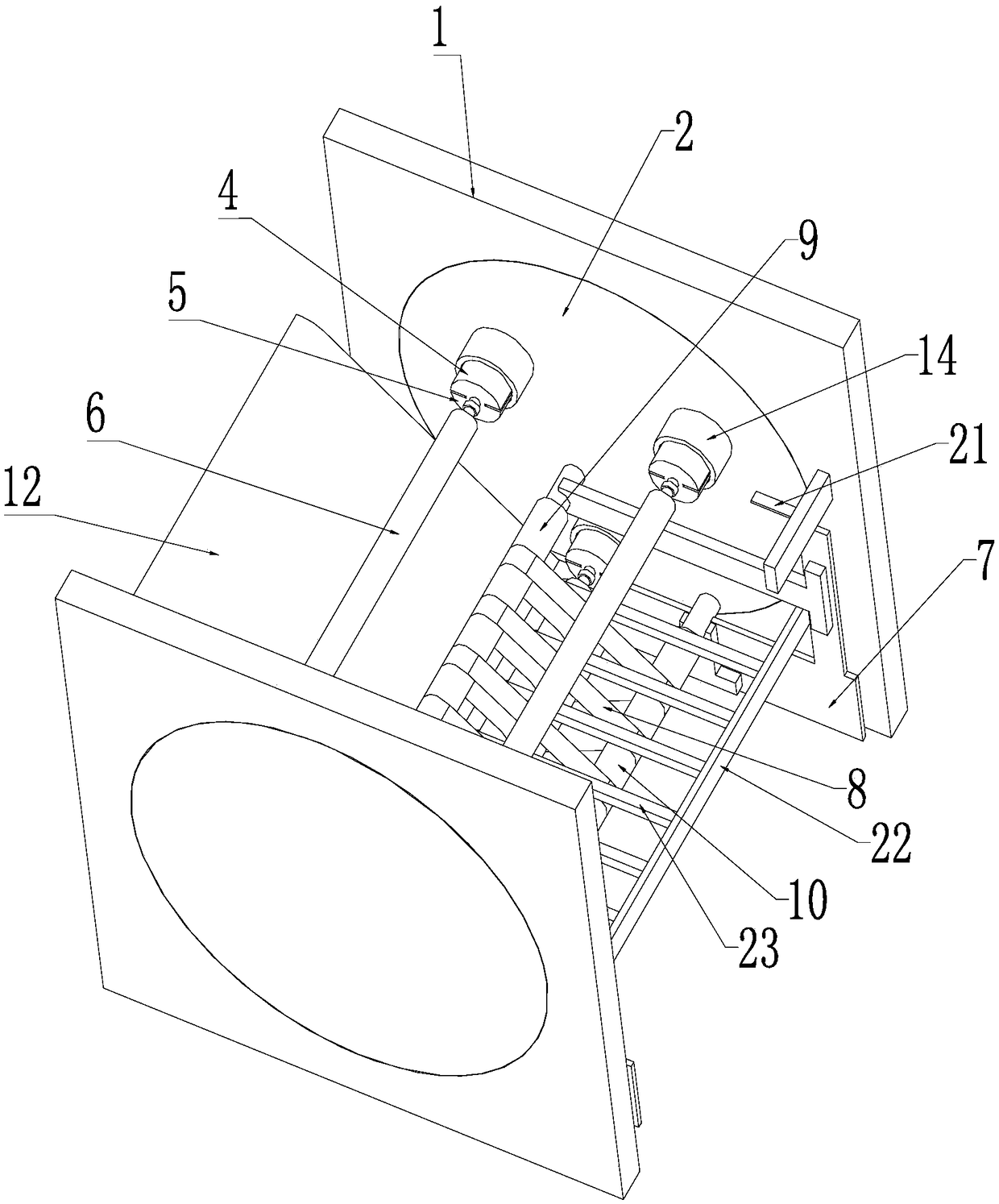

[0042] The winding device in the glass fiber mat production line includes a cutting device for cutting glass fiber strands, a settling chamber, a powder spreading device, a drying device, a compacting and shearing device, and a winding device.

[0043] The winding mechanism, the winding mechanism includes a first bracket assembly and a second bracket assembly oppositely arranged, the first bracket assembly includes a first bracket, a first rotating structure installed on the first bracket, and a first rotating structure installed on the first bracket. The first fixed seat on the rotating structure, the first fixed seat at least includes a fixed seat A, a fixed seat B, and a fixed seat C, and is distributed in the first circumferential direction centered on the rotation axis of the first rotating structure, wherein, The positions of the fixing seat A a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com